Novel spring detecting mechanism

A detection mechanism and a new type of technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unsuitable spring detection, scattered structure of the measurement workpiece, poor measurement accuracy, etc., and meet the requirements of convenient detection, compact equipment structure, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

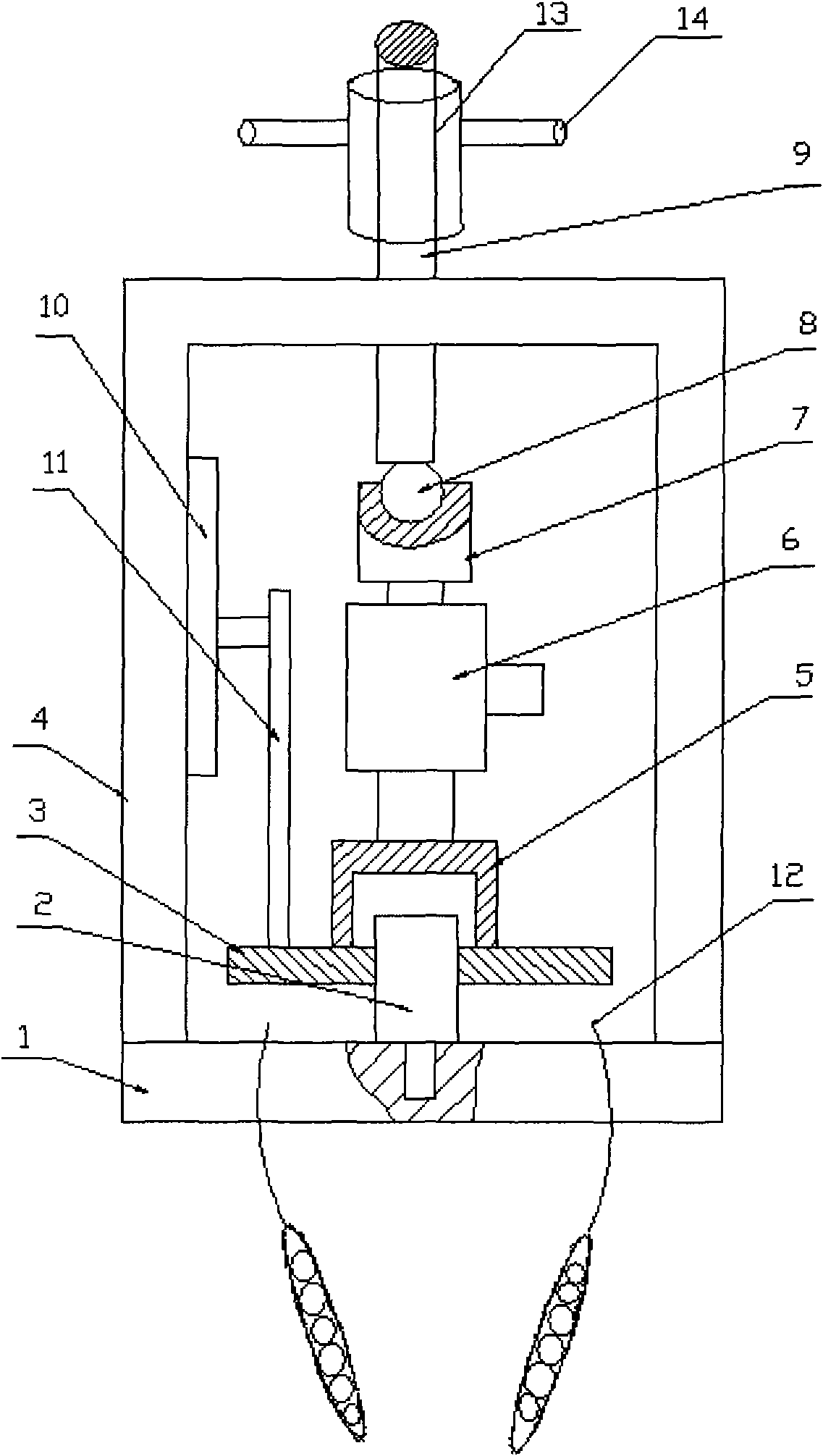

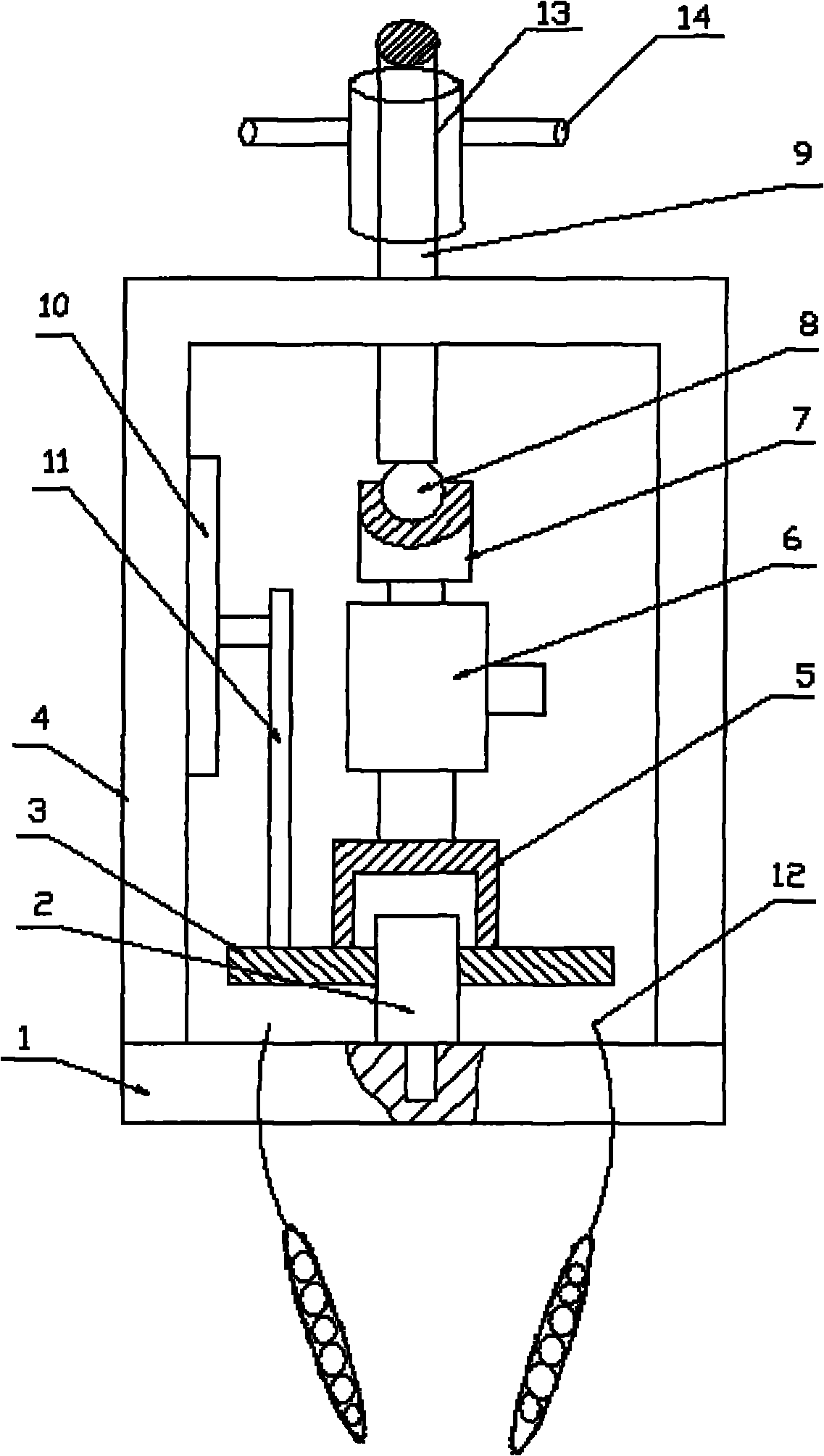

[0009] The support (4) is fixedly connected with the base (1) to form a mouth-shaped structure, the grating scale (10) is fixedly installed on the side of the support (4), and the lead screw (9) is screwed into the top of the support (4). Install the mandrel (2) on the base (1), and install the moving contact bracket (11) of the grating ruler on the pressure plate (3). A joint (7) and a pressure head (3) are respectively fixedly installed at the upper and lower ends of the pressure sensor (6). Take the center hole of the spring (12) as the positioning reference, place the spring (12) on the mandrel (2) above the base (1), and place the spring (12) so that the big mouth of the spring (12) faces the base (1), place the pressure plate (3) on the spring (12), and at the same time, align the mandrel (2) with the center hole of the pressure plate (3), and connect the pressure head ( 5) Place it at the center of the pressure plate (3), connect the moving contact of the grating scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com