Toner for electrostatic image development, toner cartridge, process cartridge and image forming apparatus

A technology for developing toner and electrostatic images, which is applied to the equipment of the electric recording process using the charge pattern, the electric recording process using the charge pattern, and the developer, etc., which can solve the problem of increasing the non-static adhesion tendency of the toner and increasing the area and other problems, to achieve the effect of reliable blockage, inhibition of adhesion, and inhibition of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

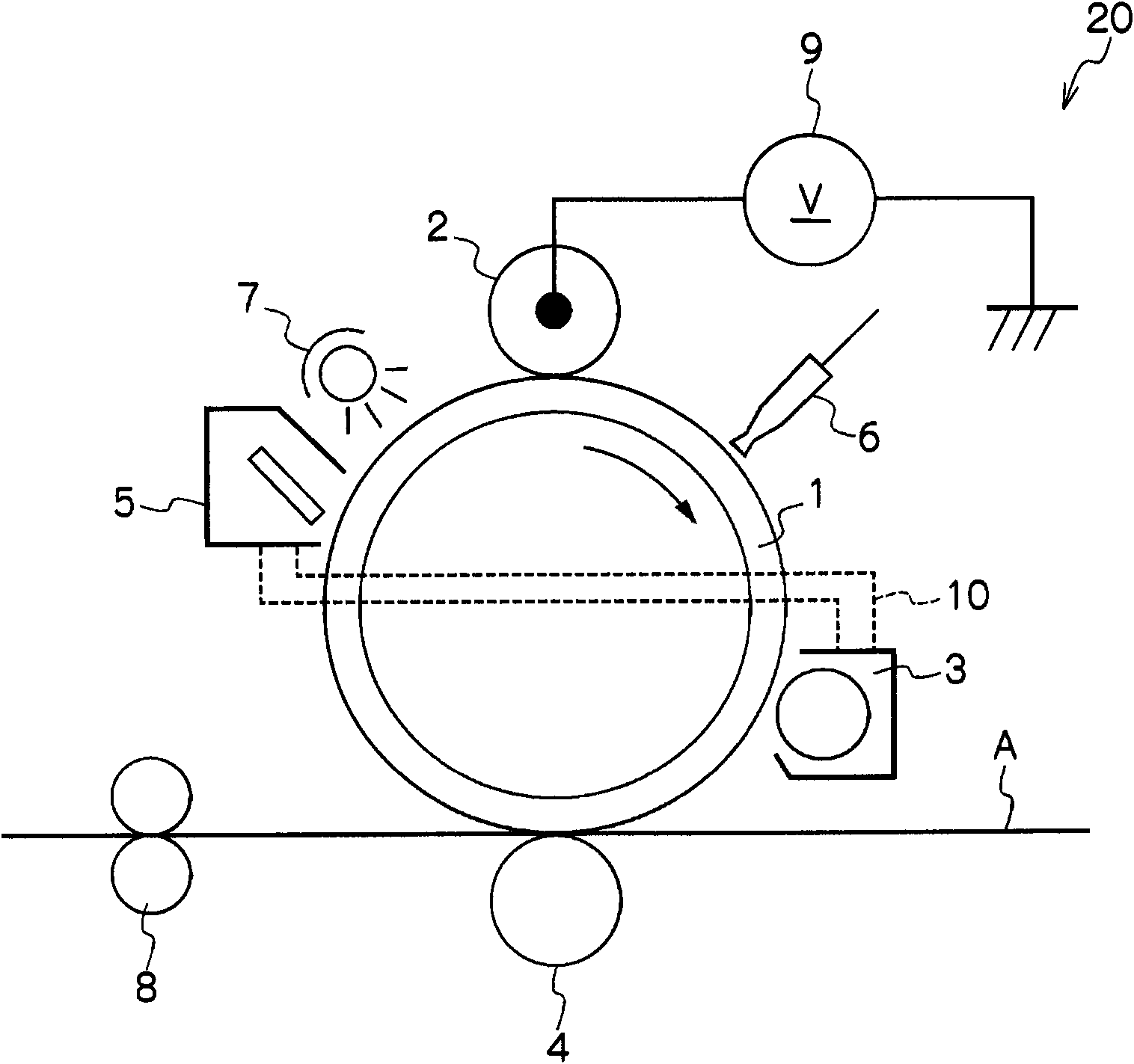

Image

Examples

Embodiment 1

[0287]

[0288] 100 parts by weight of the toner particles (1) obtained above, 1.5 parts by weight of HMDS (hexamethyldisilazane)-treated hydrophobic silica particles (primary particle diameter: 0.012 μm) and 1 part by weight of the above The obtained specific external additive particles (1) were charged into a 5 L Henschel mixer having a jacket allowing cooling water to flow therein, and were stirred using a stirring blade rotating at a peripheral speed of 28 m / s The mixture was mixed for 20 minutes at 100°C, and then coarse particles were removed by passing through a sieve having a mesh opening of 45 μm, whereby Toner (1) was obtained. The number-average number of specific external additive particles (1) attached to one particle of the toner (1) was 95.

[0289] 10 parts by weight of the obtained toner was mixed with 100 parts by weight of a carrier for Apeos Port-II C7500 manufactured by Fuji Xerox Co., Ltd. to prepare a developer, and the developer was disposed in an ima...

Embodiment 2~10

[0291]

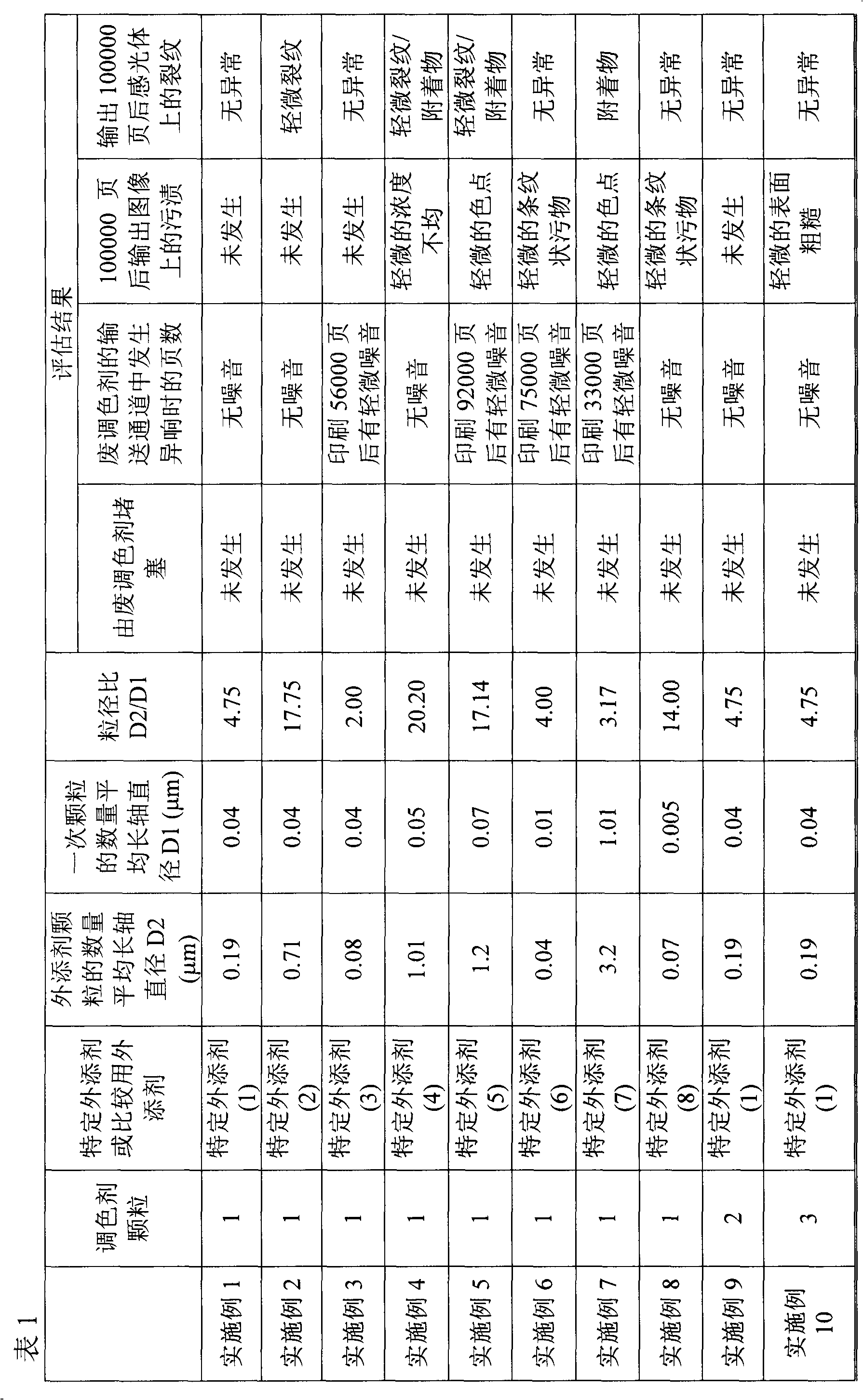

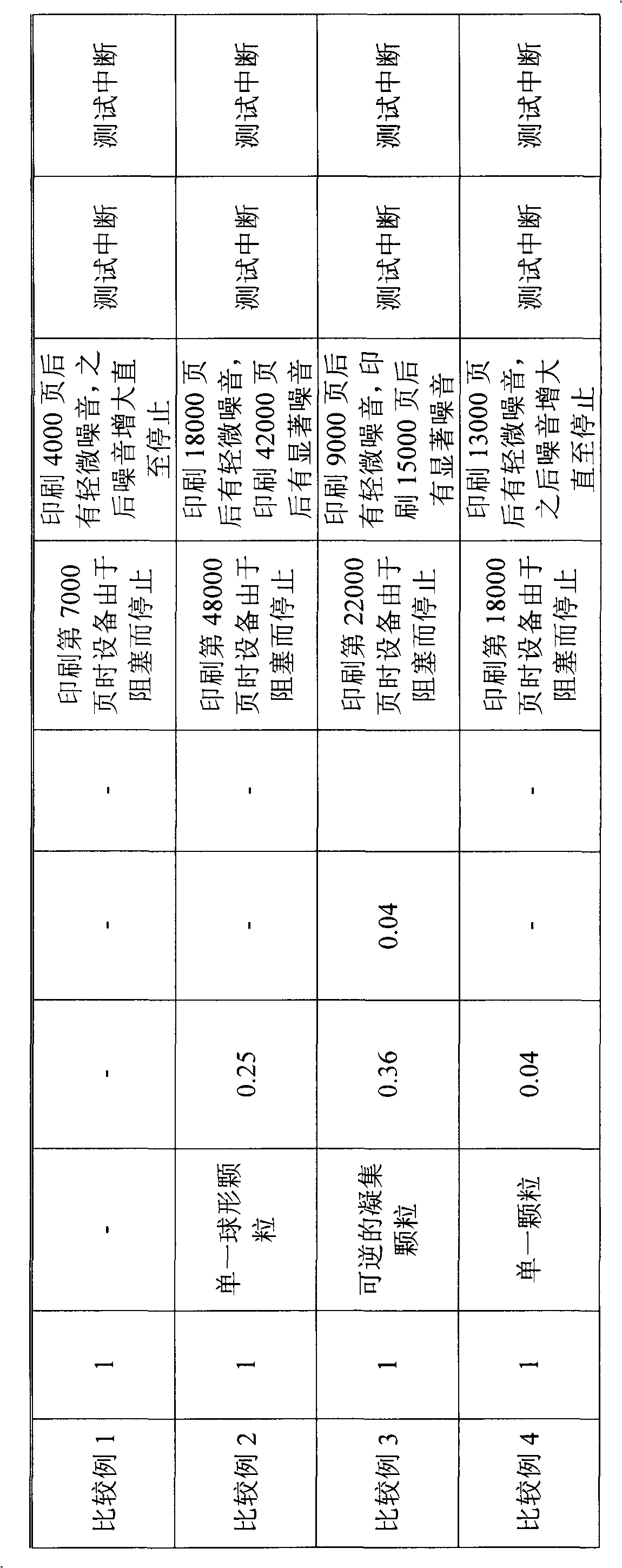

[0292] Toners (2) to (10) were obtained in the same manner as the preparation of toner (1) except that the toner particles, specific external additive particles and other ingredients were combined as shown in Table 1 . The number average number of specific external additive particles attached to one particle of each toner is: 7 in Example 2, 350 in Example 3, 6 in Example 4, 4 in Example 5, In Example 6, it was 400, in Example 7, it was 1.5, in Example 8, it was 280, in Example 9, it was 71, and in Example 10, it was 87.

[0293] When each of these toners was configured in an image forming apparatus in the same manner as in Example 1 and evaluated, redispersion of the specific external additive particles to the primary particles was hardly observed. At this time, the redispersion rate was 2 number % in Example 2, 5 number % in Example 3, 0 number % in Example 4, 12 number % in Example 5, and 12 number % in Example 6. 7 number % in Example 7, 10 number % in Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com