Gas compressor

A technology of gas compressors and cylinder blocks, which is applied in liquid fuel engines, mechanical equipment, machines/engines, etc., and can solve the problems of large-scale and weight gas compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

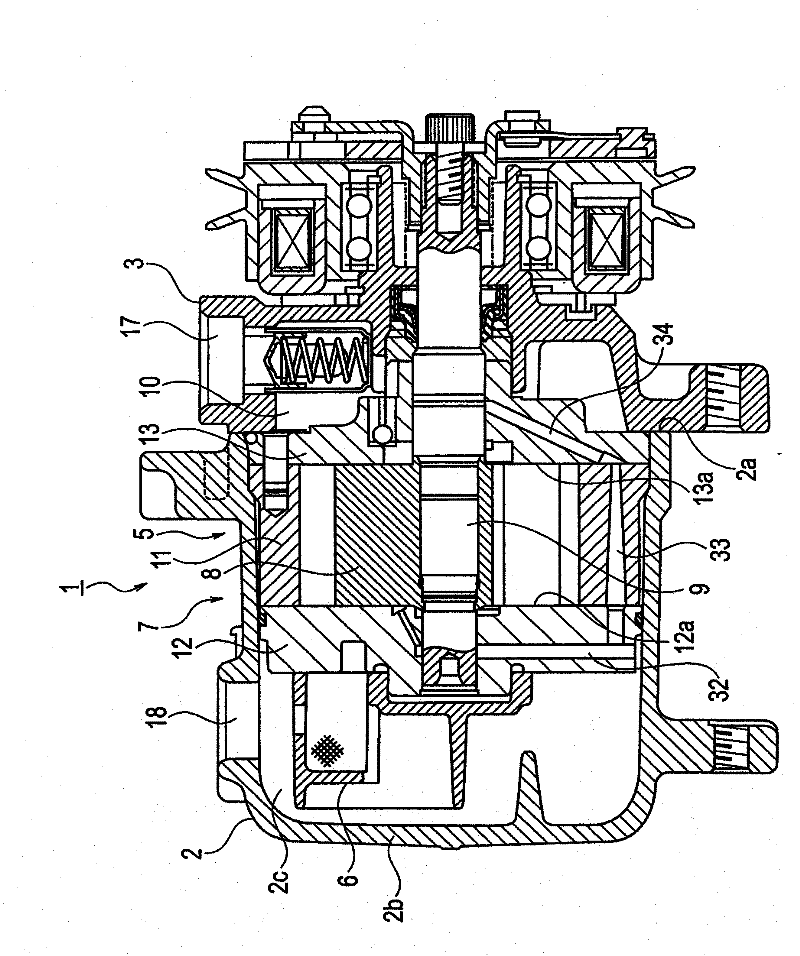

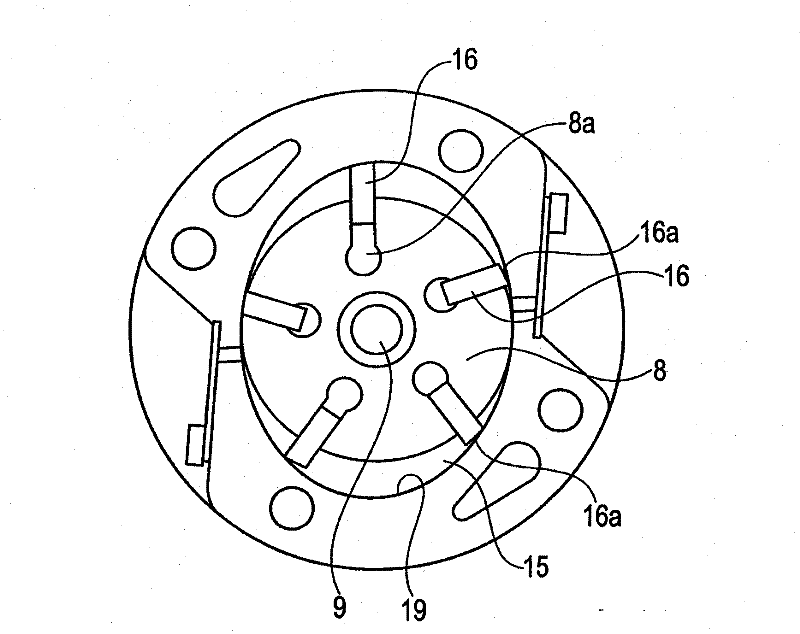

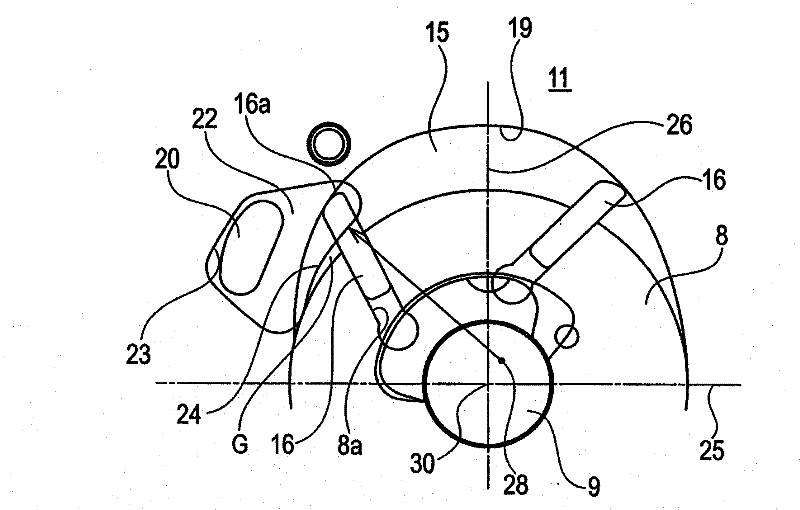

[0017] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

[0018] The gas compressor 1 of this embodiment is a vane rotary compressor. like figure 1 As shown, the gas compressor 1 has a housing 2 and a compression mechanism 5 .

[0019] The housing 2 has a bottomed cylindrical shape whose rear end is closed by a bottom wall 2b. The compression mechanism 5 and the gas-liquid separation unit 6 are accommodated in the housing portion 2c inside the casing 2 . A discharge port 18 for the refrigerant is formed on the upper portion of the casing 2 . An opening 2 a is formed at the front end of the housing 2 . On the side of the opening 2a of the housing 2, a front cylinder head (head) 3 is fixed. On the front cylinder head 3, a suction port 17 for sucking refrigerant into the compression mechanism 5 is formed. The suction port 17 communicates with the suction chamber 10, and the suction chamber 10 communicates with the suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com