Horizontal seamed energy dissipation prestressed shear wall structure

A prestressed and shear wall technology, applied in the direction of structural elements, walls, building components, etc., can solve the problems of poor energy dissipation capacity and large structural displacement, and achieve simple structure, small residual structural deformation, and good self-resetting ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

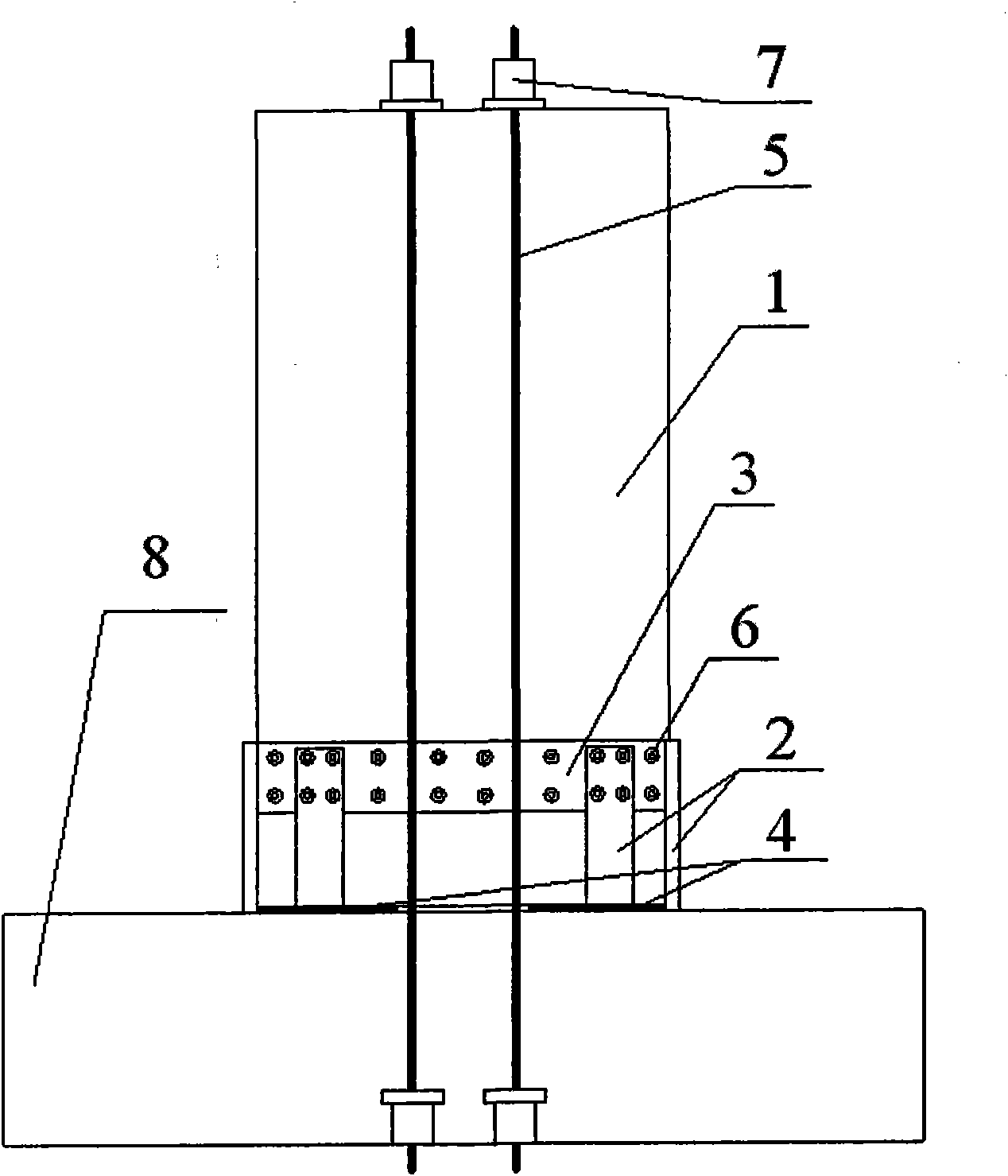

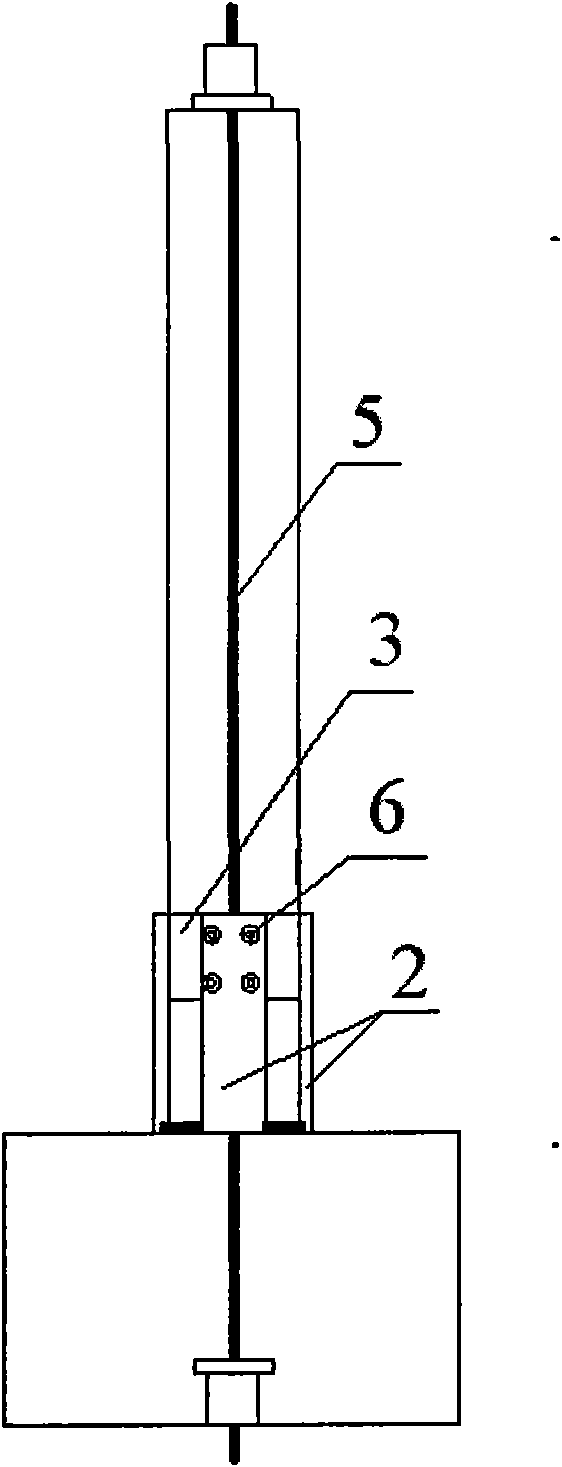

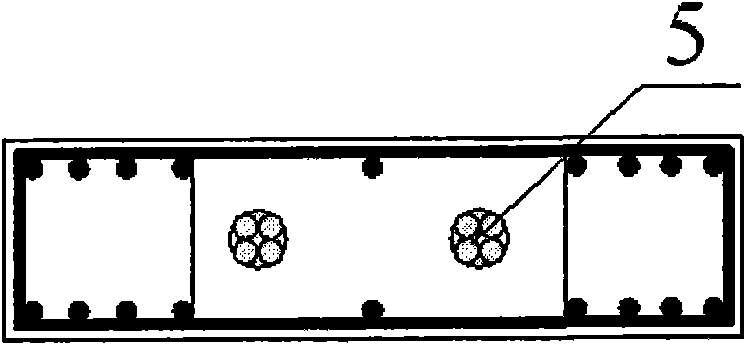

[0027] Such as Figure 1-4 As shown, a horizontal slotted energy-dissipating prestressed shear wall structure of the present invention includes a reinforced concrete wall 1, an energy-dissipating device 2, connecting steel plates 3, horizontal joints 4, prestressed tendons 5, high-strength bolts 6, and anchor fittings 7 and foundation 8, the section of the prestressed shear wall is rectangular (such as Figure 3-4 ), the bottom of the reinforced concrete wall 1 is provided with a foundation 8, and symmetrical horizontal joints 4 are arranged in the horizontal direction of the reinforced concrete wall 1, and the horizontal joints 4 are arranged at the bottom of the reinforced concrete wall or at positions of different heights. The steel bar is disconnected at the horizontal joint 4, the reinforced concrete wall 1 is provided with a connecting steel plate 3, the energy dissipation device 2 spans the horizontal joint 4 up and down, one end is connected with the connecting steel p...

Embodiment 2

[0029] The prestressed shear wall section of the present invention is L type (as Figure 5-6 ), all the other structures are the same as in Embodiment 1, and will not be described in detail here.

Embodiment 3

[0031] Prestressed shear wall section of the present invention is T-shaped (as Figure 7-8 ), all the other structures are the same as in Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com