Controllable high-pressure high-flow generating device and control method thereof

A technology of a generating device and a control method, which is applied to fluid pressure actuation devices, fluid pressure actuation system testing, mechanical equipment, etc., can solve problems such as high hardware cost, high system power, and uncontrollable output flow rate, and achieve extended The effect of flow output time, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

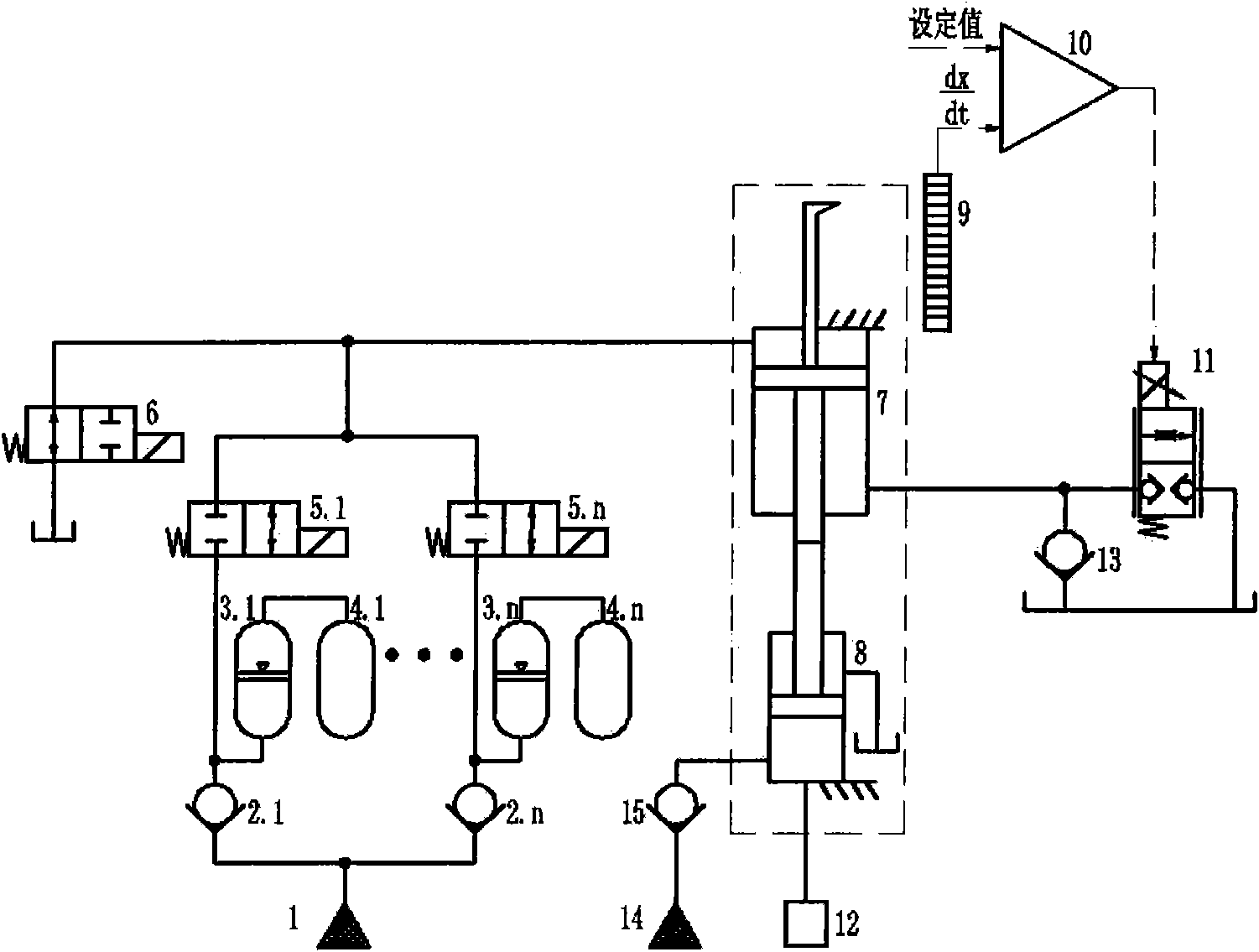

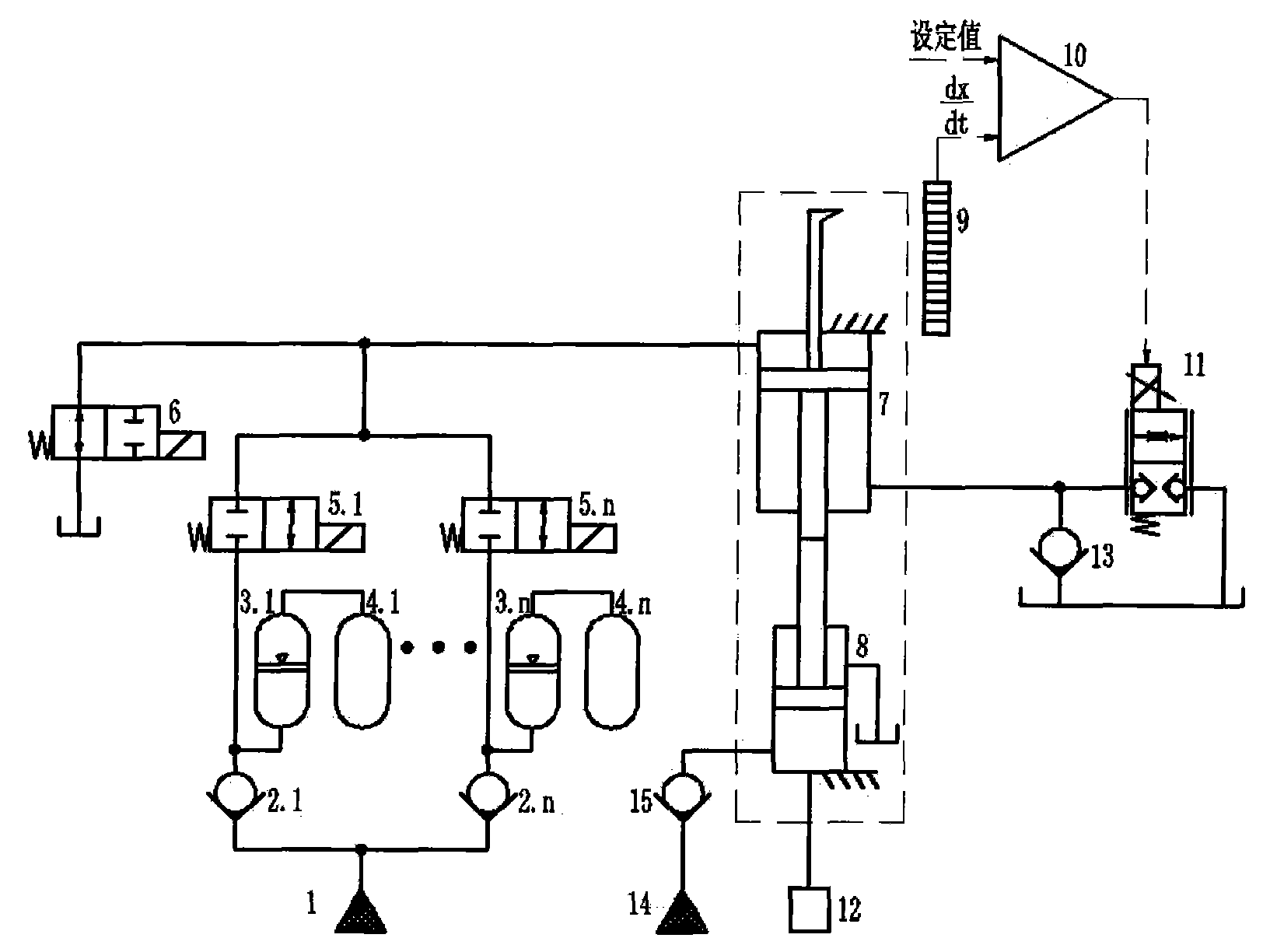

[0011] The preferred embodiment of the controllable high pressure and large flow generating device of the present invention is:

[0012] It includes a pump source, an accumulator group, a supercharger, a control valve group, and a flow detection and control device. The supercharger includes a low-pressure end hydraulic cylinder and a high-pressure end hydraulic cylinder with relatively fixed cylinders and piston rods facing each other. The pump source is connected to the rodless chamber of the hydraulic cylinder at the low pressure end through a plurality of pipelines connected in parallel, and each pipeline is provided with a separate accumulator and a two-position two normally closed directional control valve. The hydraulic cylinder is connected with a flow control device.

[0013] The accumulator set includes multiple piston accumulators and gas cylinders.

[0014] A one-way valve and a reversing valve are respectively arranged between the pump source and the accumulator o...

specific Embodiment

[0026] Specific examples, such as figure 1 shown, including:

[0027] 1. Hydraulic system, specifically including:

[0028] Pump source 1:

[0029] The pump source 1 can adopt different configurations and parameters according to the needs, and the illustration only shows the function symbol of the pump source;

[0030] Accumulator:

[0031] Various forms of accumulators can be used, such as figure 1 Shown is a better solution, using one or more piston accumulators (number: 3.1, 3.2...3.n) combined with one or more gas cylinders (number: 4.1, 4.2...4.n), the The method can make full use of the volume of the accumulator itself under a small pressure drop.

[0032] The combination of the accumulator in the specific embodiment is that a piston accumulator and a gas cylinder group form an accumulator, and the number of accumulators formed is two or more, connected in parallel, and multiple The accumulators output the flow sequentially by opening at the same time or relaying. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com