Thin-film solar panel array

A technology of solar panels and solar cells, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., and can solve problems such as shedding, self-heavyness, and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

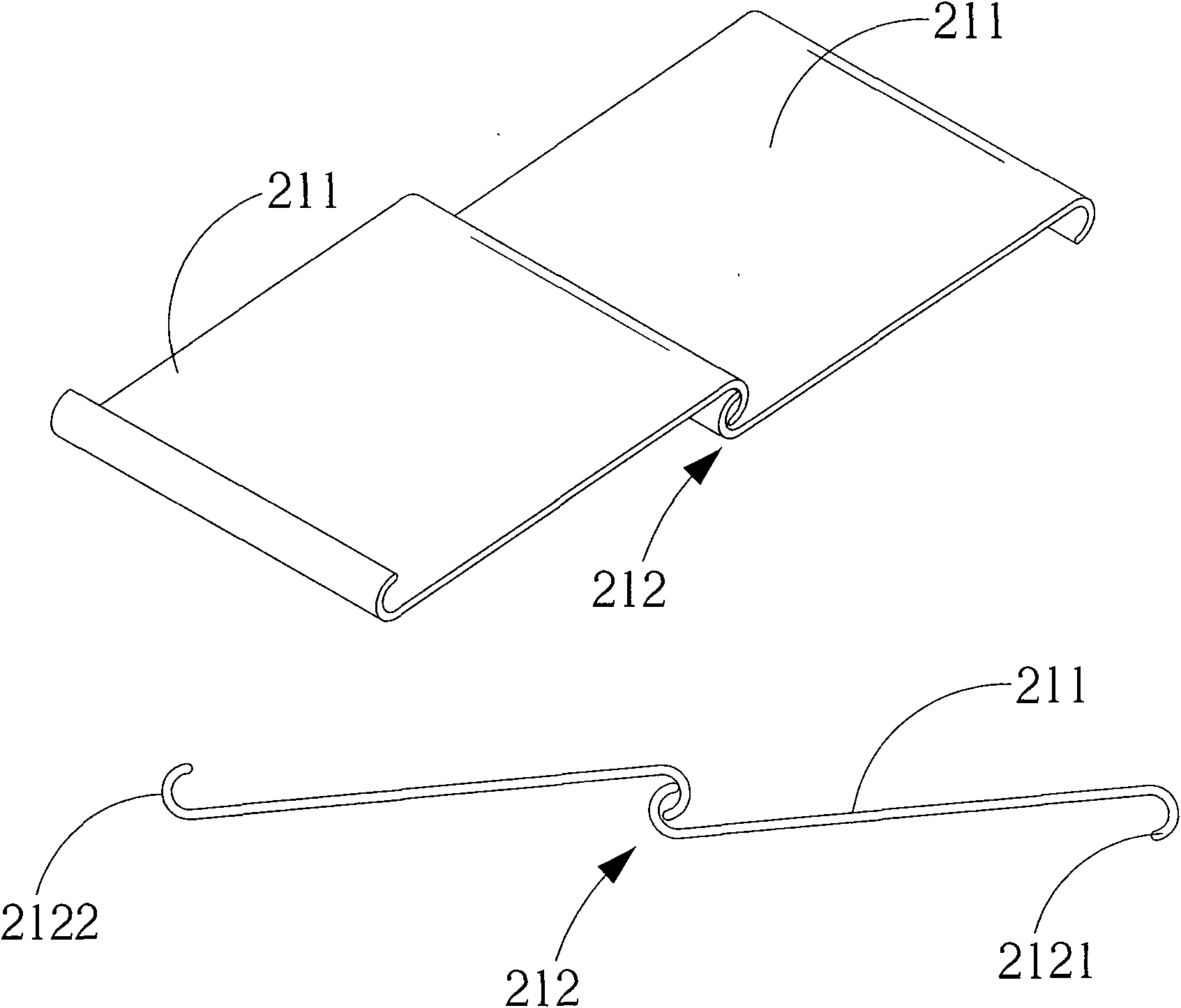

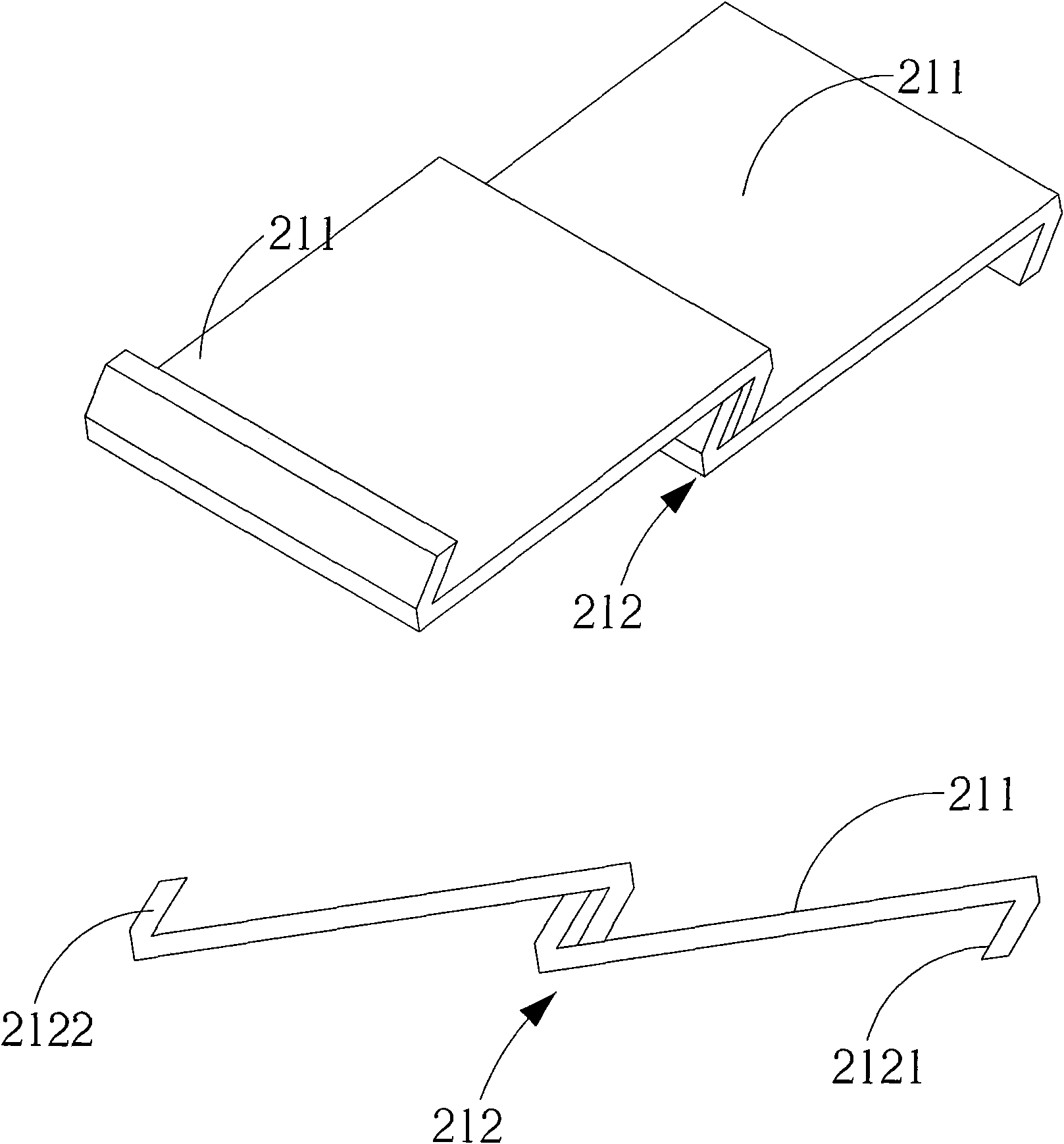

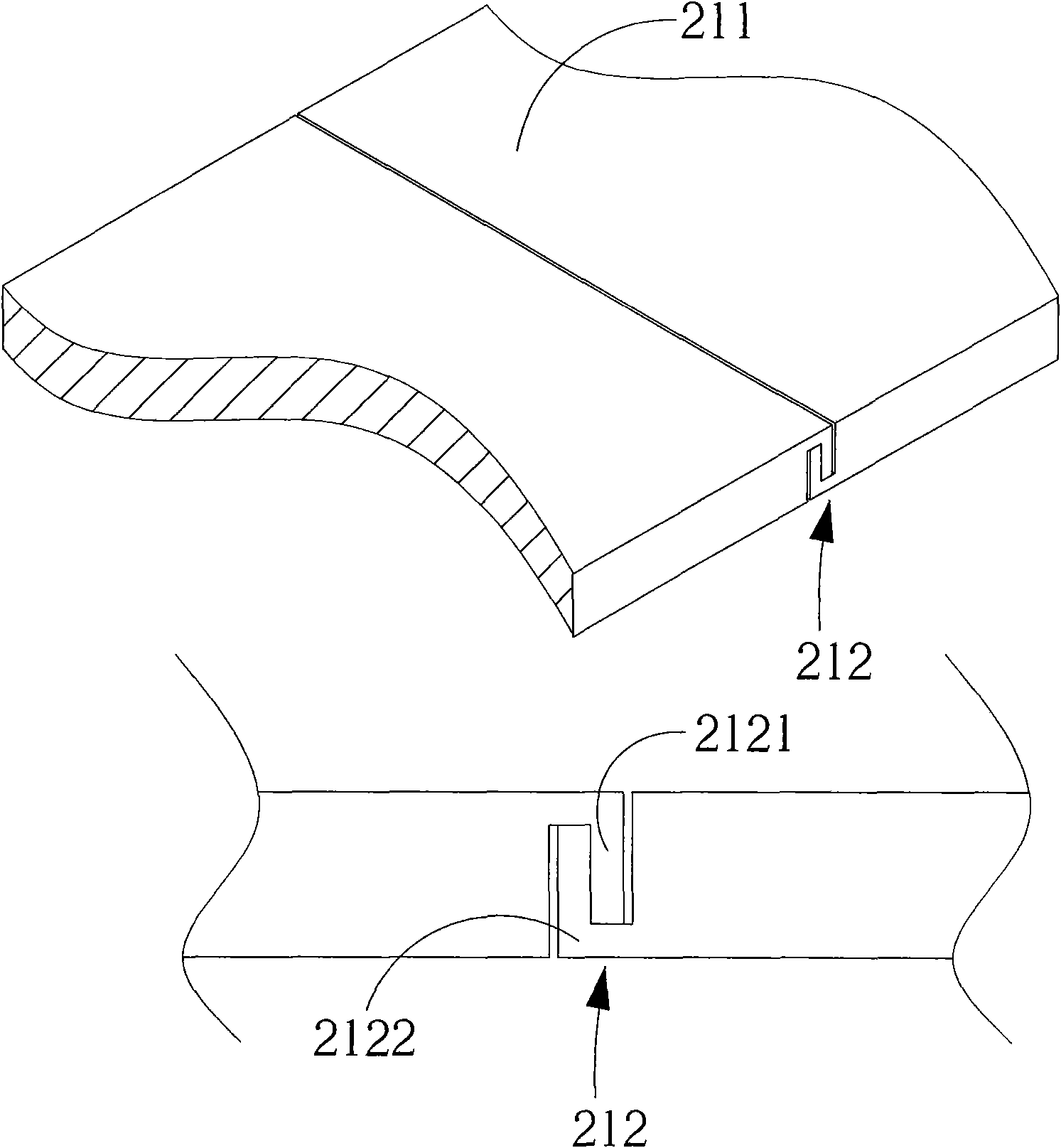

[0032] See Figure 1 to Figure 9 , the present invention is a thin film solar panel array, including a fixing frame 1, and a thin film solar panel chain 2. The thin film solar panel chain 2 includes a first thin film solar panel component 21 and a second thin film solar panel component 22 .

[0033] The fixing frame 1 is used for setting on an inclined plane, and includes a supporting beam 11 arranged transversely on the upper part of the fixing frame 1 .

[0034] Each of the first thin film solar cell panel member 21 and the second thin film solar cell panel member 22 includes a thin film solar cell panel 211 and a fixing member 212 .

[0035] The thin film solar panel 211 includes a conductive glass, a back electrode is attached to the back of the conductive glass, and a resin coating is coated on the back of the back electrode and the edge of the conductive glass and the back electrode, and the back electrode is separated from the air. isolated.

[0036] The fixing part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com