Improved production process of braking rail

A production process and a technology for braking rails, applied in metal rolling and other directions, can solve the problems of high energy consumption, complex process, waste of raw materials, etc., and achieve the effect of improving safety and reliability, simple process flow, and consistent line combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

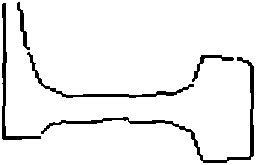

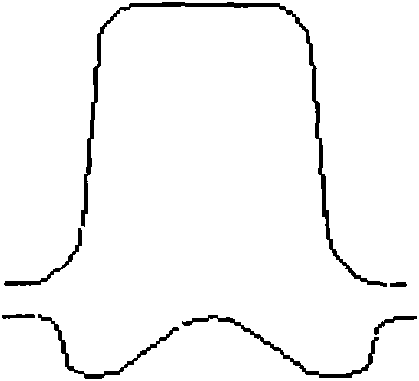

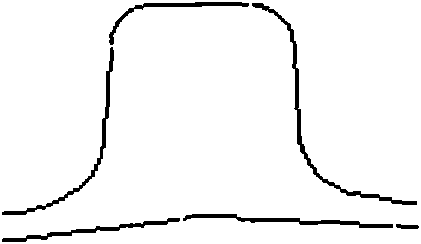

[0016] The brake rail is rolled from a rectangular billet or square billet. The steel billet is rolled along the center line of the thickness by rollers with different functions, and rolled sequentially according to the thickness requirements of the shape of the brake rail to form a whole. The rolls are divided into billet rolls, semi-formed rolls and formed rolls

[0017] The rolling method of the brake rail is to heat the rectangular billet or square billet to a high temperature above 1100°C in the heating furnace, and then send it to the billet rolling mill for rolling. Different pass shapes, and the passes are configured on the rolls, and multiple passes of different shapes can be configured according to the length of the roll body. The upper and lower rollers form a pass. When working, the upper and lower rollers rotate simultaneously, and the rolled piece is rolled into different shapes, and finally rolled into the shape of the brake rail. In the rolling process, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com