Multi-tube detonation lateral wave ignition device

An ignition device and transverse wave technology, applied in rocket engine devices, jet propulsion devices, intermittent jet devices, etc., can solve the problems of insufficient specific impulse, inability to keep up with the working frequency, difficulties, etc., and achieve the effect of shortening the length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

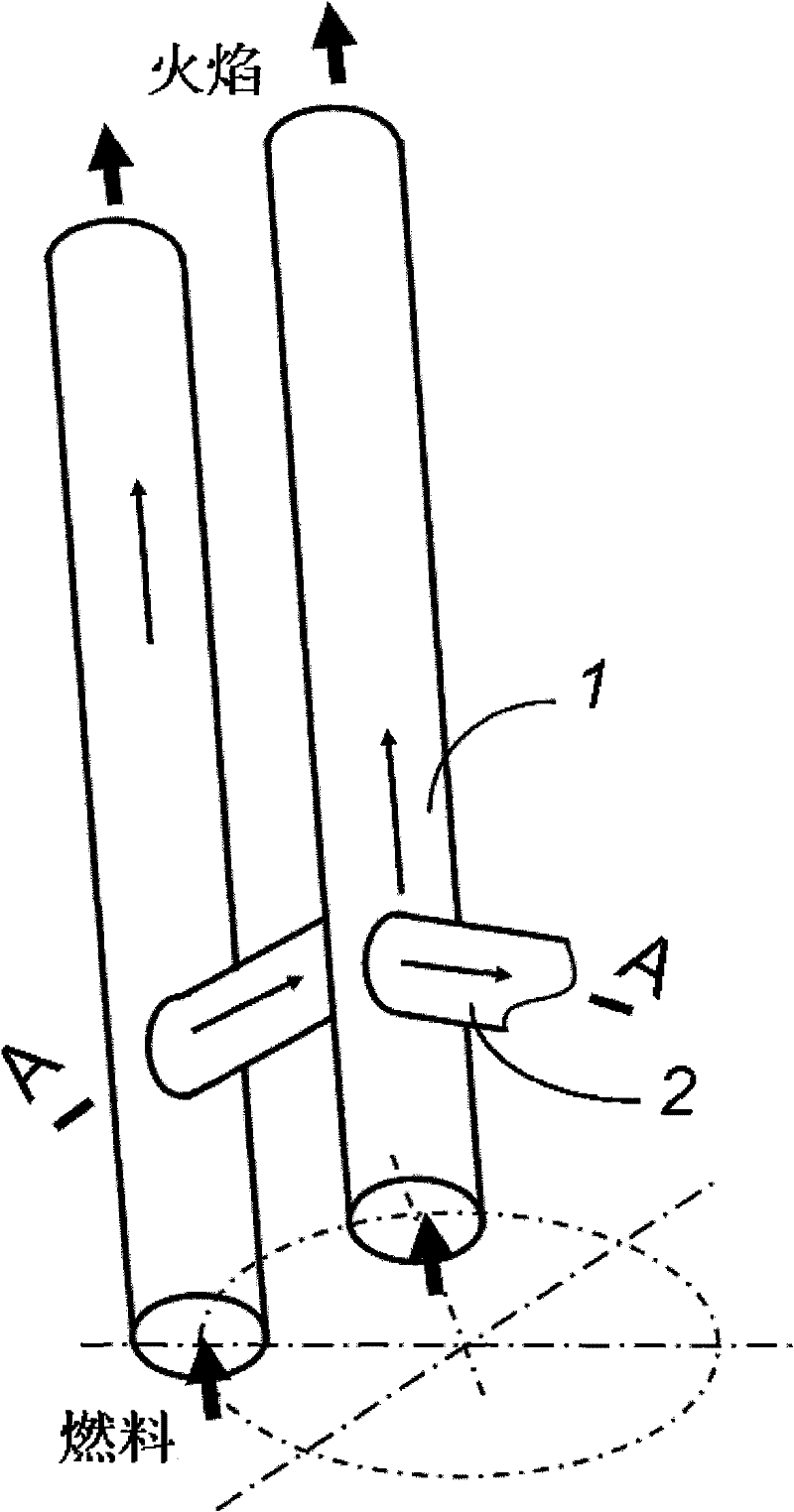

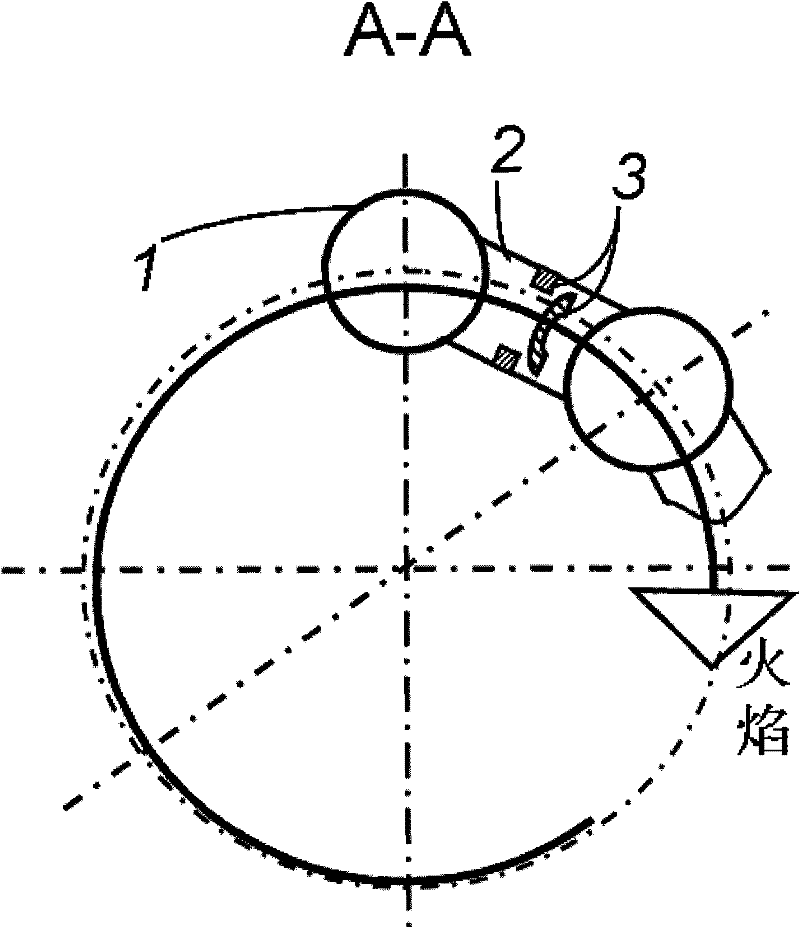

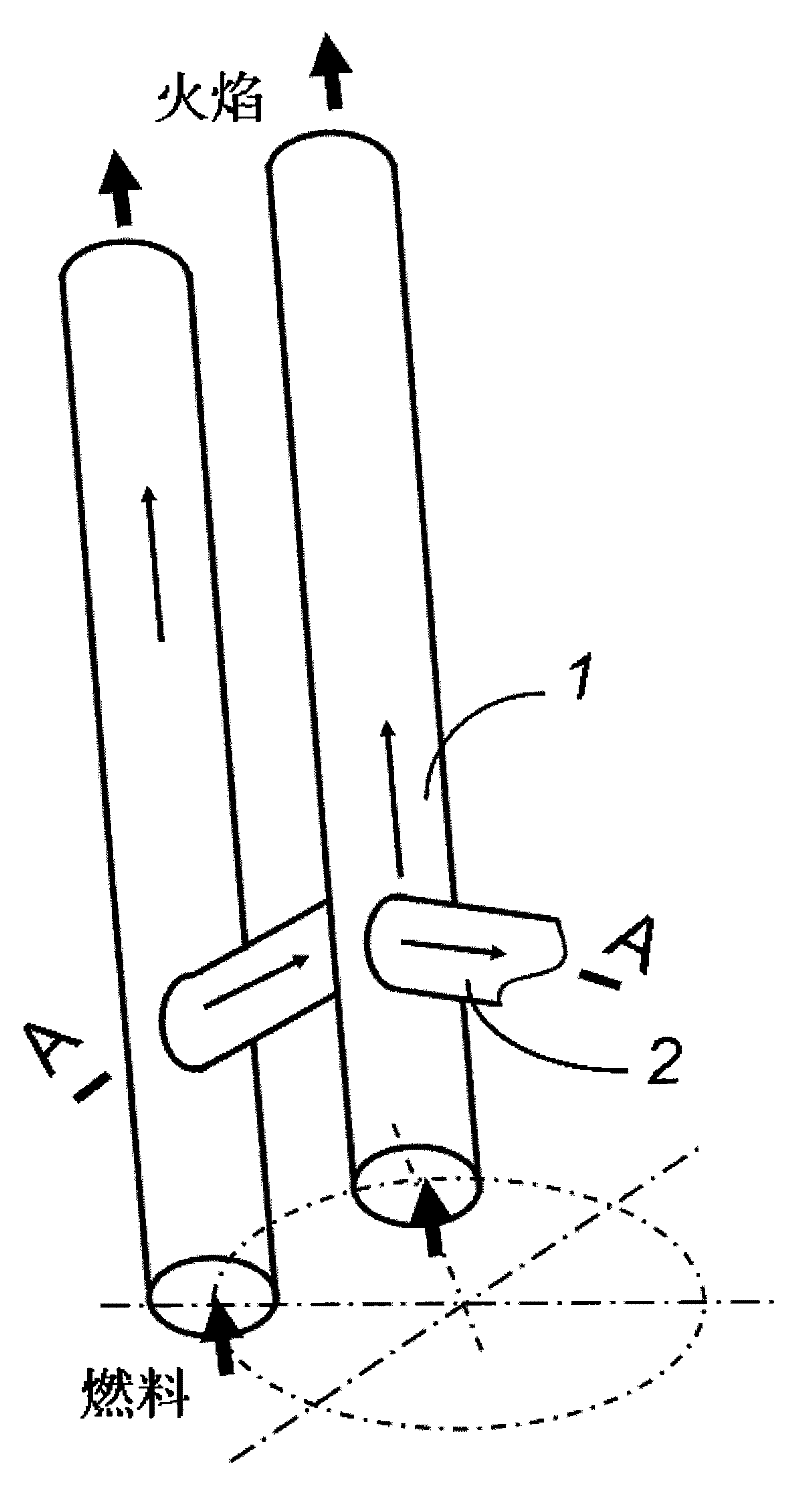

[0030] Preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing: See figure 1 and figure 2 , the multi-tube detonation transverse wave ignition device comprises a plurality of parallel parallel detonation tubes 1, a transverse flame tube 2 and a flame check valve assembly 3, adjacent detonation tubes 1 are formed by a transverse flame tube near the entrance thereof 2 are connected; a flame check valve assembly 3 is arranged in the horizontal flame tube 2; each group of detonation tube 1, horizontal flame tube 2 and flame check valve assembly 3 is arranged in a chain and connected end to end. The premixed fuel that has been charged in the detonation tube 1 is ignited by the ignition device set near the entrance of the detonation tube 1 to generate an initial flame, and the flame propagates in two ways, one is to propagate toward the outlet nozzle of the detonation tube, To generate thrust, the other path passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com