Scanning gauge

A technology of scanning gauges and indicator tables, which is applied in the field of scanning gauges, can solve the problems of unrealistic measurement, low rotation accuracy, unreasonable structure, etc., and achieve the effect of simple structure, smooth rotation, and convenient reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

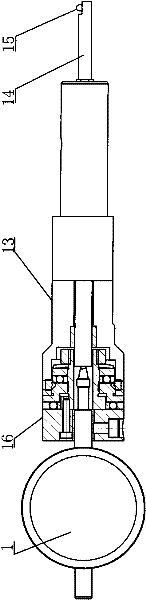

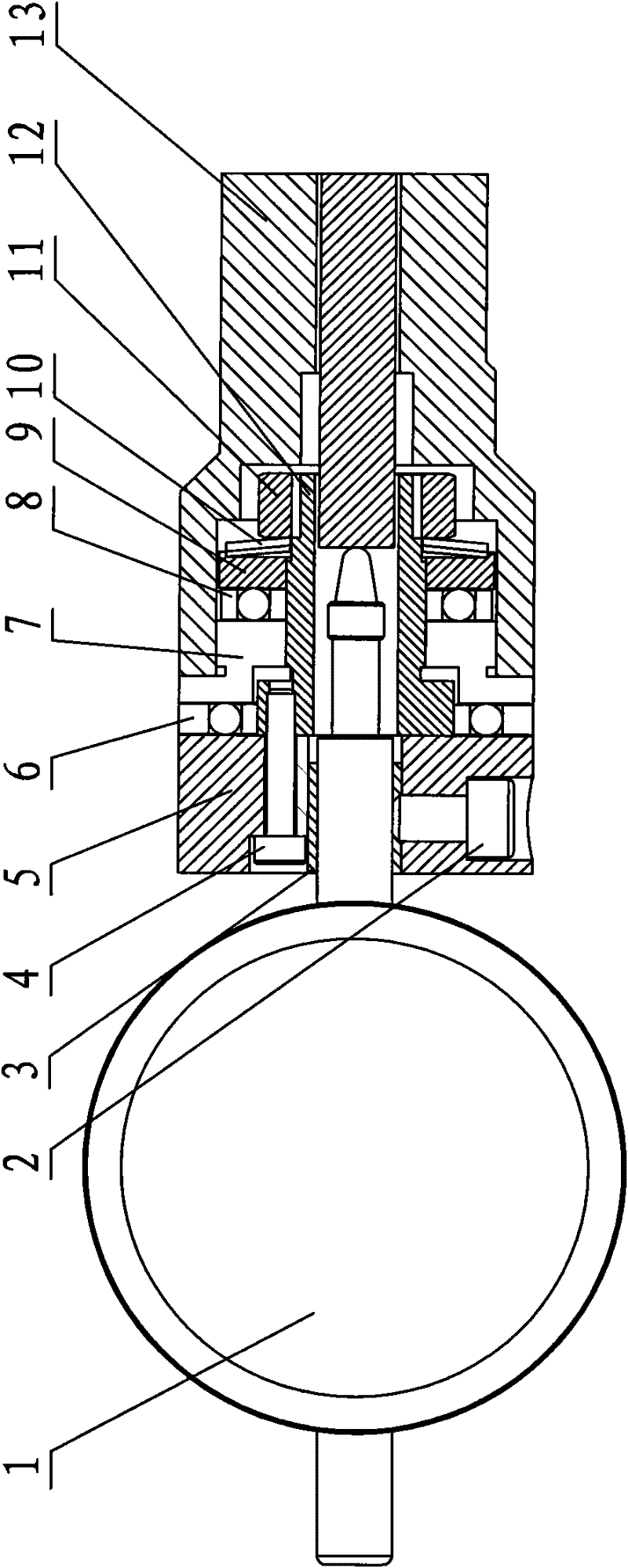

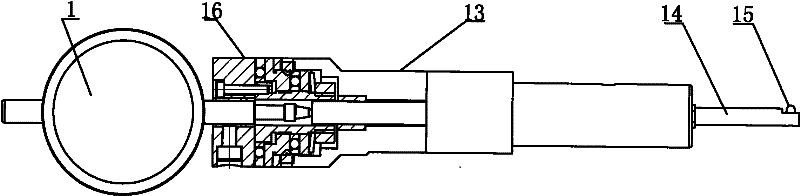

[0017] The present invention, a kind of scanning gauge, its specific embodiment is:

[0018] Such as figure 1 and figure 2 As shown, the measuring head 15, the measuring rod 14, the handle 13, the rotating mechanism 16 and the indicating table 1 are sequentially connected, wherein the other end of the measuring rod 14 passes through the handle 13 and is connected with the contact head of the indicating table 1, and the rotating mechanism 16 will The indicating meter 1 and the handle 13 are connected into an integral structure, and the handle 13 can be rotated arbitrarily, and the indicating meter 1 can be kept still, and the measurement result can be read directly by looking at the meter, so as to achieve the purpose of quick measurement.

[0019] The rotating mechanism 16 includes a table base 5 and a fixed sleeve 12, and one end of the table base 5 is provided with an end face bearing I6, a connecting piece 7, an end face bearing II8, a retaining piece 9, a disc spring 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com