Device for automatically online-detecting abrasion of pantograph pan of locomotive

A technology for automatic detection of pantograph slides, applied to measuring devices, instruments, and optical devices, etc., can solve the problems of difficult automatic analysis and judgment of pantograph photos, failure of ultrasonic waves to return to the receiving unit, and inability to obtain the surface state of slides, etc. , to achieve the effect of reducing purchase cost, convenient operation and use, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

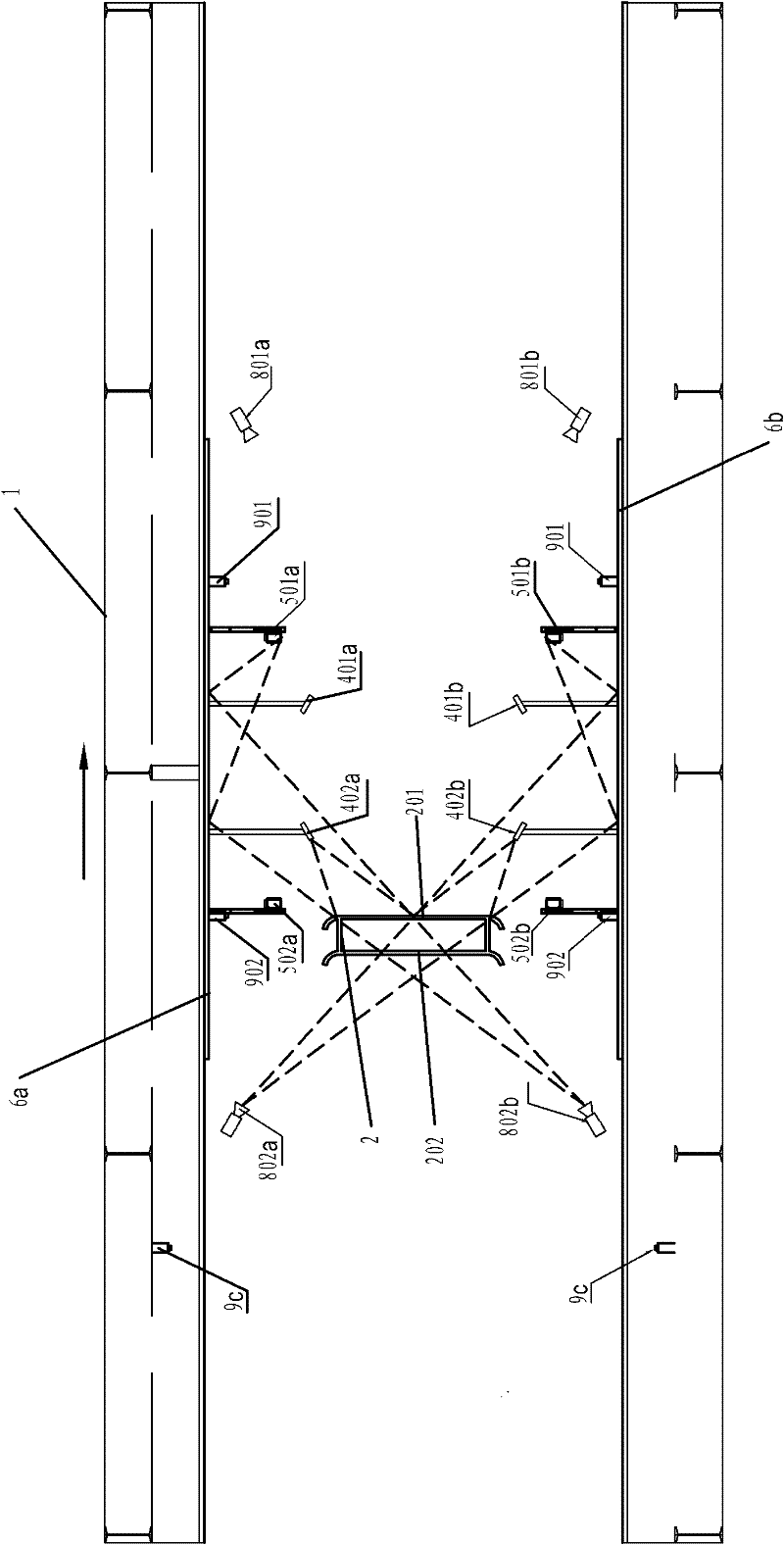

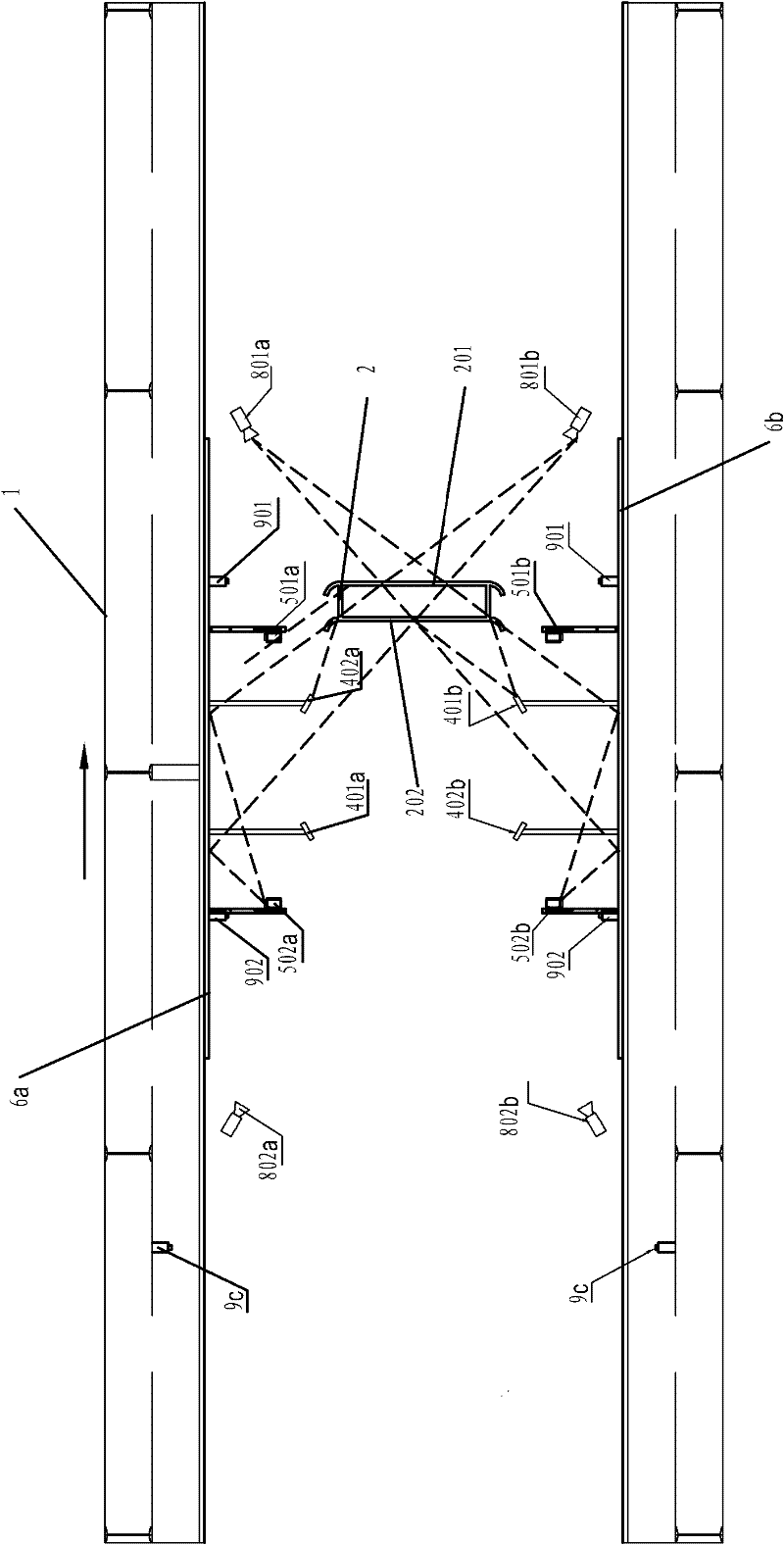

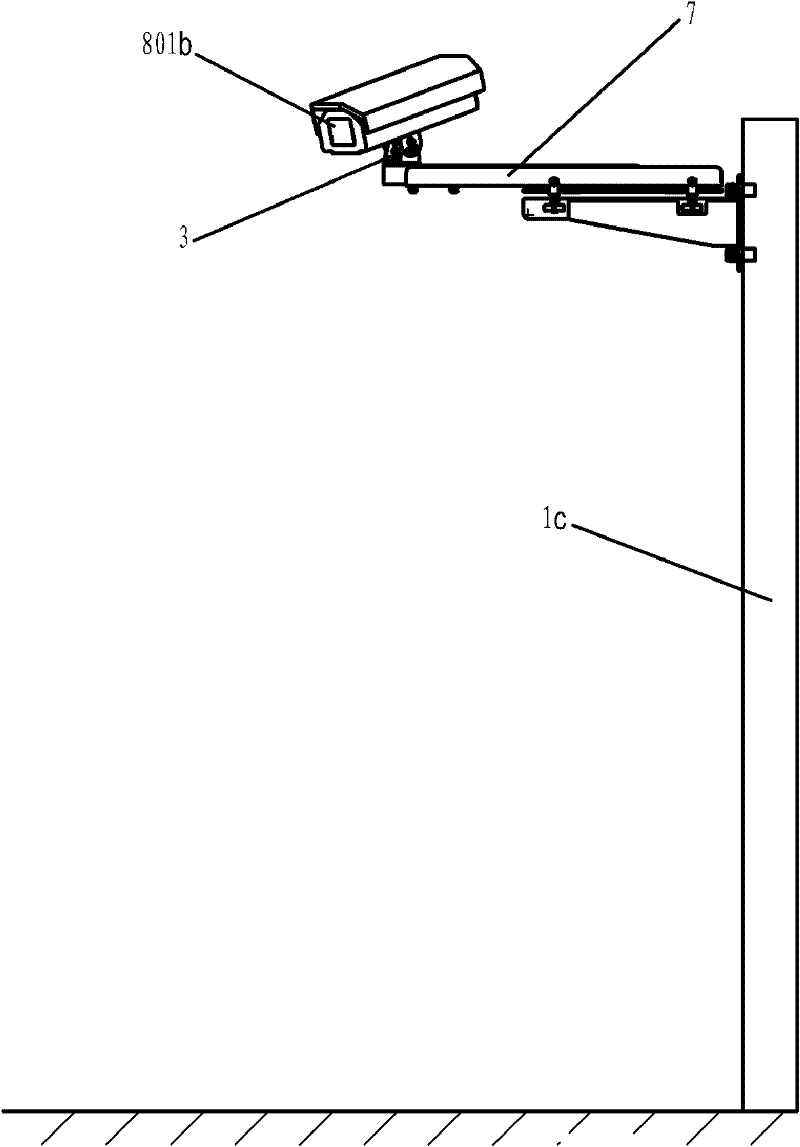

[0035] figure 1 , 2 Shown is an on-line automatic detection equipment for pantograph sliding plate wear of a locomotive, including an image sensor installed on the detection booth 1, and a data processing and control device connected with the image sensor.

[0036] Front and rear trigger switches 901 and 902 connected to the data processing and control device are respectively fixed at the front and rear positions on the side of the detection booth 1 at the same height as the locomotive pantograph 2, and the left and right sides of the detection booth 1 are respectively equipped with left and right trigger switches. , Right background panels 6a, 6b;

[0037] There are four image sensors installed on the detection booth 1, which are respectively left rear, right rear, left front, and right front image sensors 802a, 802b, 801a, 801b according to their installation positions;

[0038] figure 1 It is shown that the viewing angles of the left and right rear image sensors 802a and 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com