Voltage adjustment and electricity theft prevention device for motor of oil extractor

A technology for voltage regulation and anti-theft electricity, which is applied in the direction of automatic disconnection of emergency protection devices, circuit devices, AC motor control, etc. good, the effect of improving operating efficiency and power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

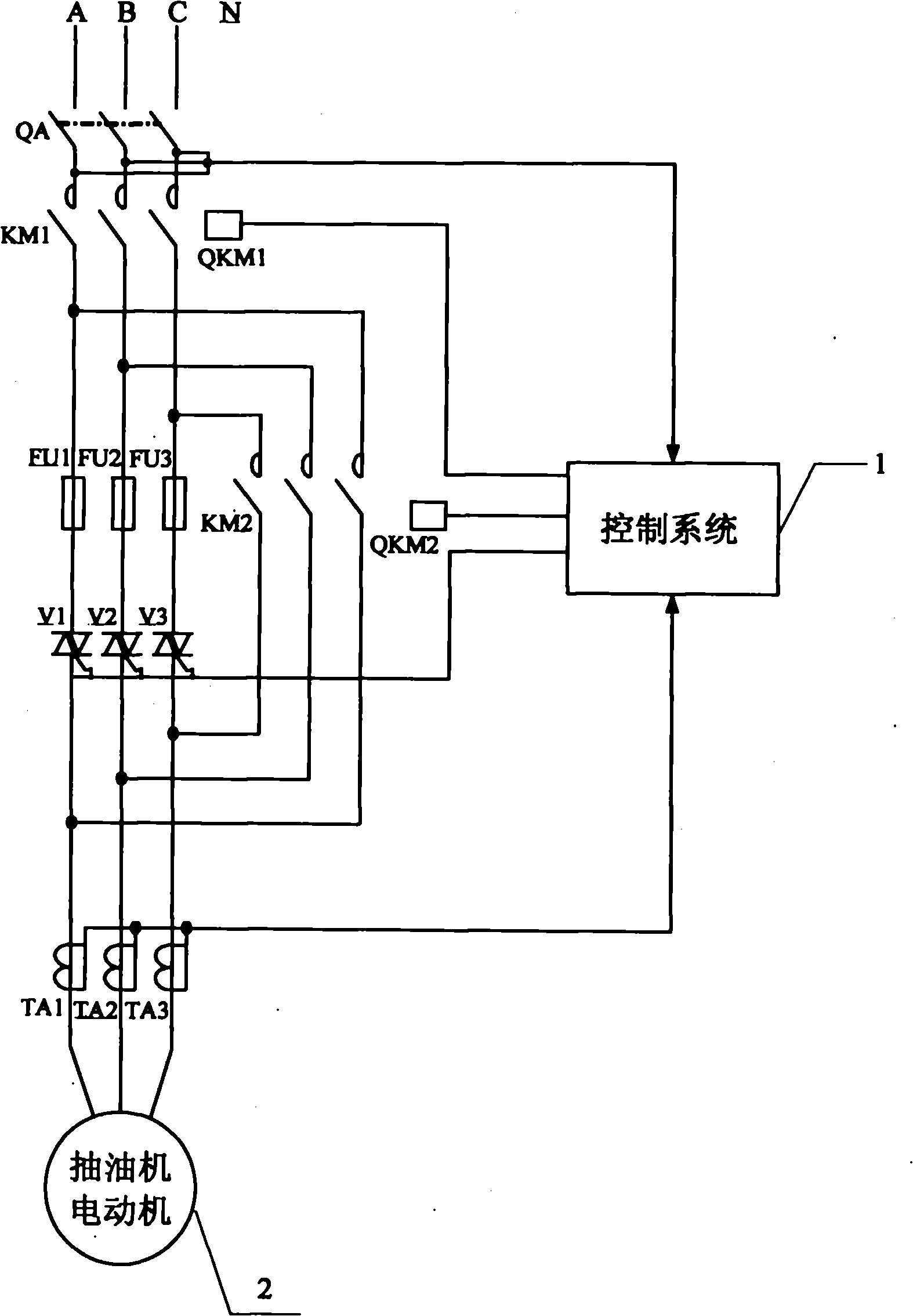

[0008] Specific implementation mode 1. Combination figure 1 Illustrate this specific embodiment, the voltage regulation and anti-theft electric device of pumping unit motor, it comprises pumping unit motor 2, it also comprises first AC contactor KM1, second AC contactor KM2, No. 1 thyristor V1, No. 2 thyristor Thyristor V2, No. 3 thyristor V3, first current transformer TA1, second current transformer TA2, third current transformer TA3 and control system 1, the A-phase static terminal and B-phase static terminal of the first AC contactor KM1 terminal and C-phase static terminal are connected to the three-phase power supply at the same time, and the A-phase dynamic terminal, B-phase dynamic terminal and C-phase dynamic terminal of the first AC contactor KM1 are respectively connected to the power input terminal of the first thyristor V1 and the second thyristor The power input terminal of V2 is connected to the power input terminal of the No. 3 thyristor V3, and the A-phase movi...

specific Embodiment approach 2

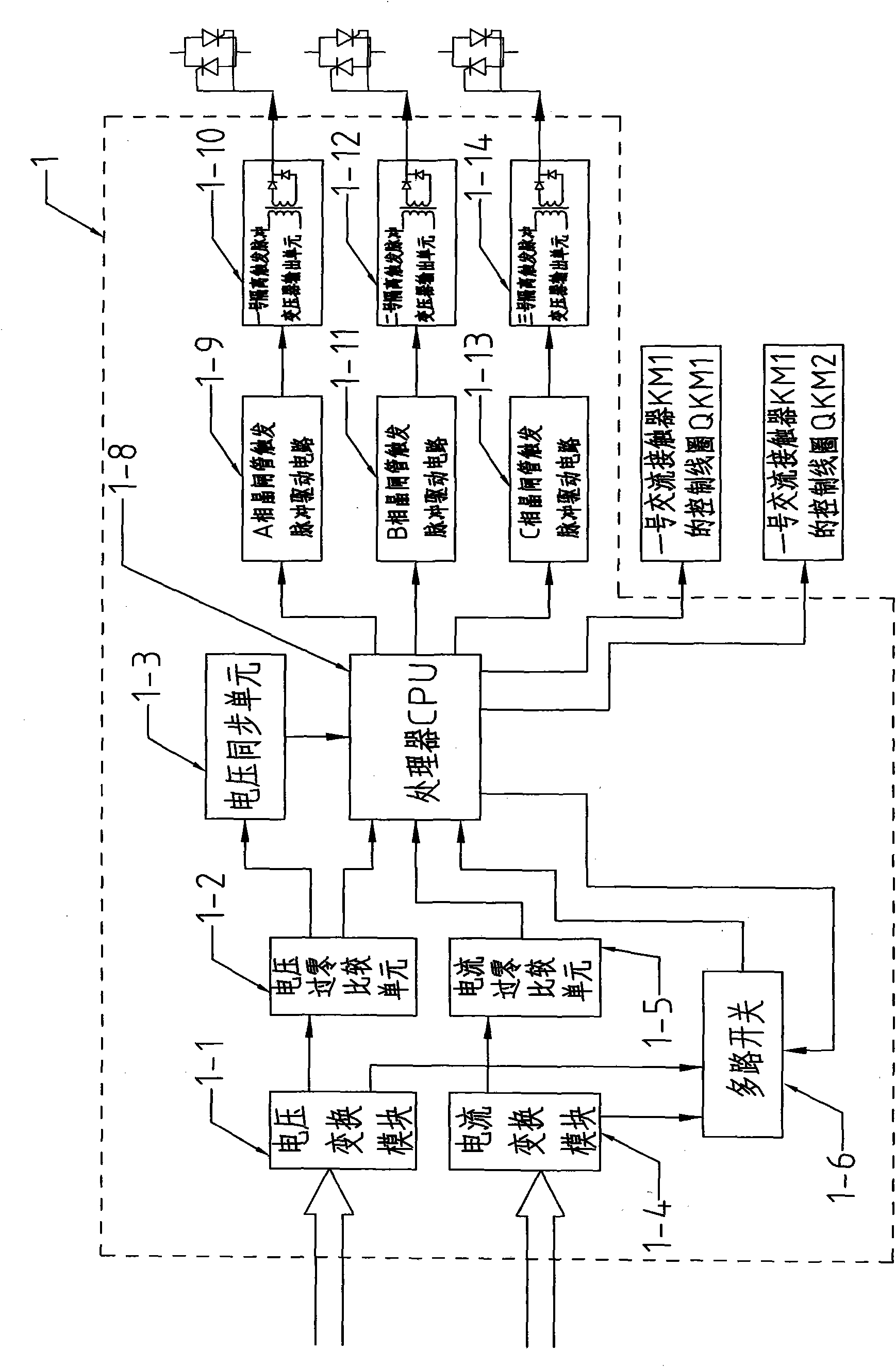

[0015] Specific embodiment two, combine figure 2 Describe this specific embodiment, the difference between this specific embodiment and the voltage regulation and anti-theft electric device of the pumping unit motor described in the first specific embodiment is that the control system 1 includes a voltage conversion module 1-1, a voltage zero-crossing comparison unit 1 -2. Voltage synchronization unit 1-3, current conversion module 1-4, current zero-crossing comparison unit 1-5, multi-way switch 1-6, processor CPU 1-8, A-phase thyristor trigger pulse drive circuit 1-9, No. 1 isolated trigger pulse transformer output unit 1-10, B-phase thyristor trigger pulse drive circuit 1-11, No. 2 isolated trigger pulse transformer output unit 1-12, C-phase thyristor trigger pulse drive circuit 1-13 and No. 2 isolated trigger The pulse transformer output unit 1-14, the No. 1 output terminal of the voltage conversion module 1-1 is connected to the input terminal of the voltage zero-crossing...

specific Embodiment approach 3

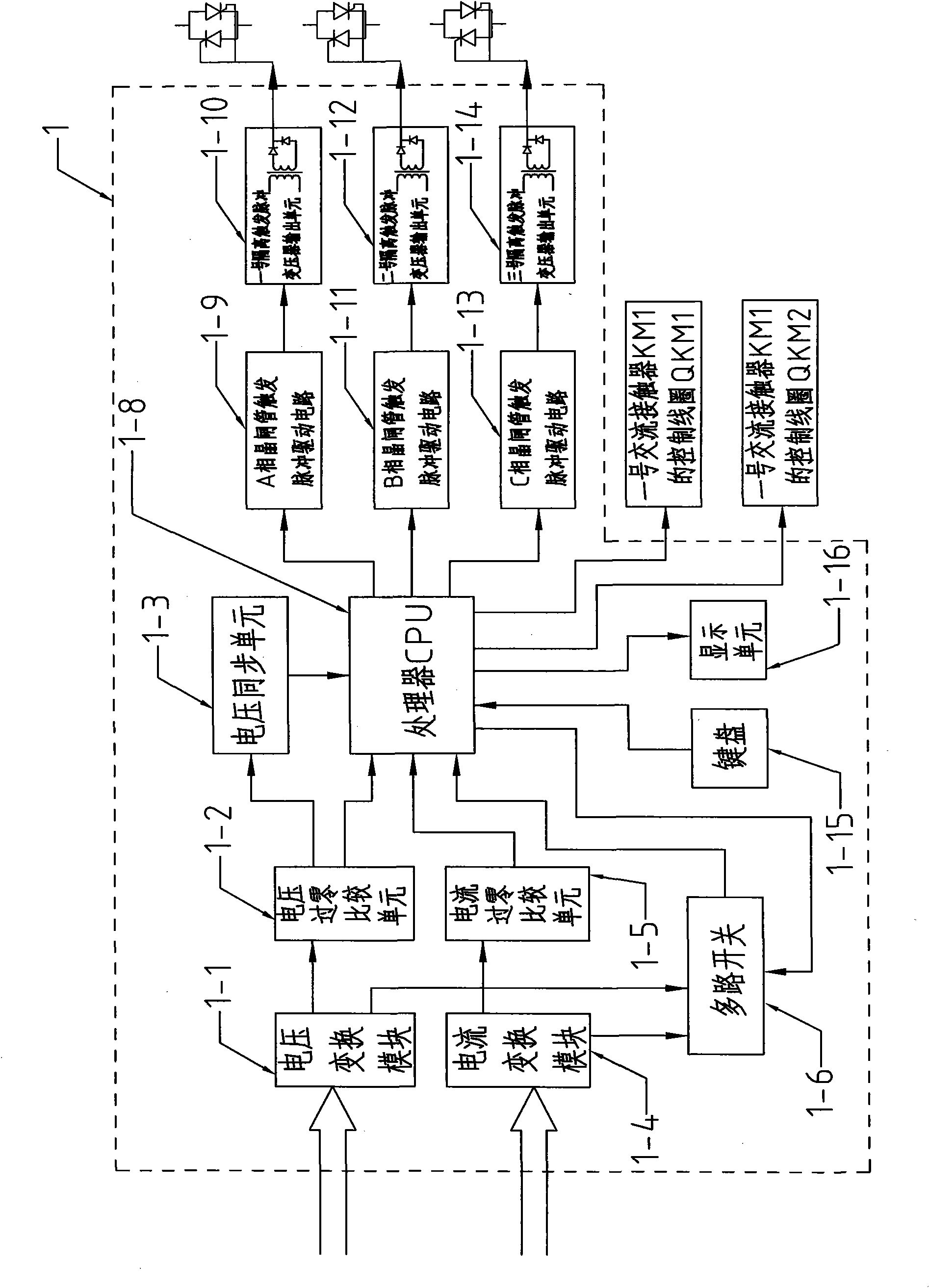

[0020] Embodiment 3. The difference between this embodiment and the voltage regulation and anti-theft electric device of the pumping unit motor described in Embodiment 2 is that it also includes a keyboard 1-15, and the keyboard signal output of the keyboard 1-15 End is connected with the keyboard signal input end of processor CPU1-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com