Forming apparatus

A technology of forming table and forming roller is applied in the field of forming devices for reducing diameter to achieve the effect of reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

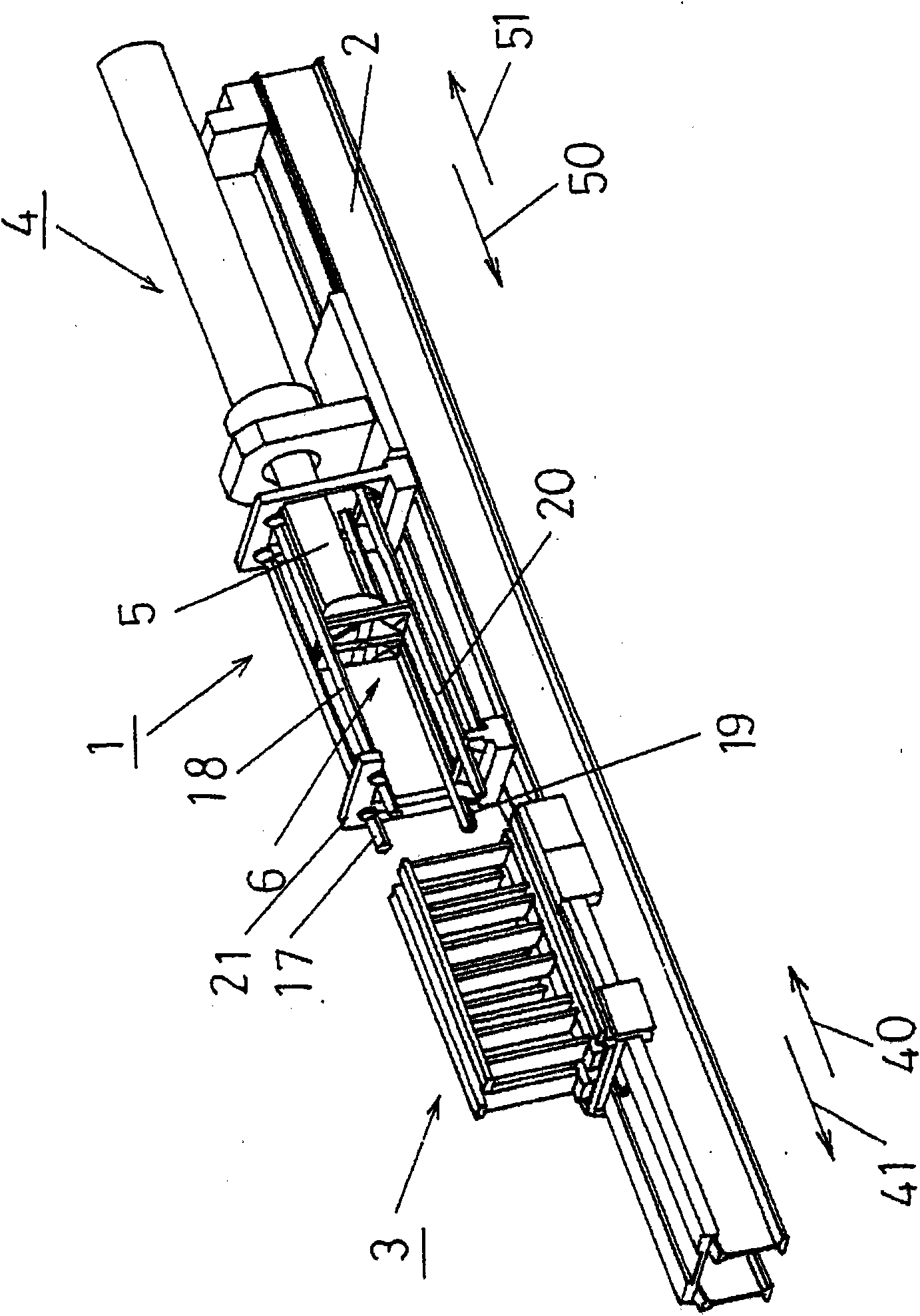

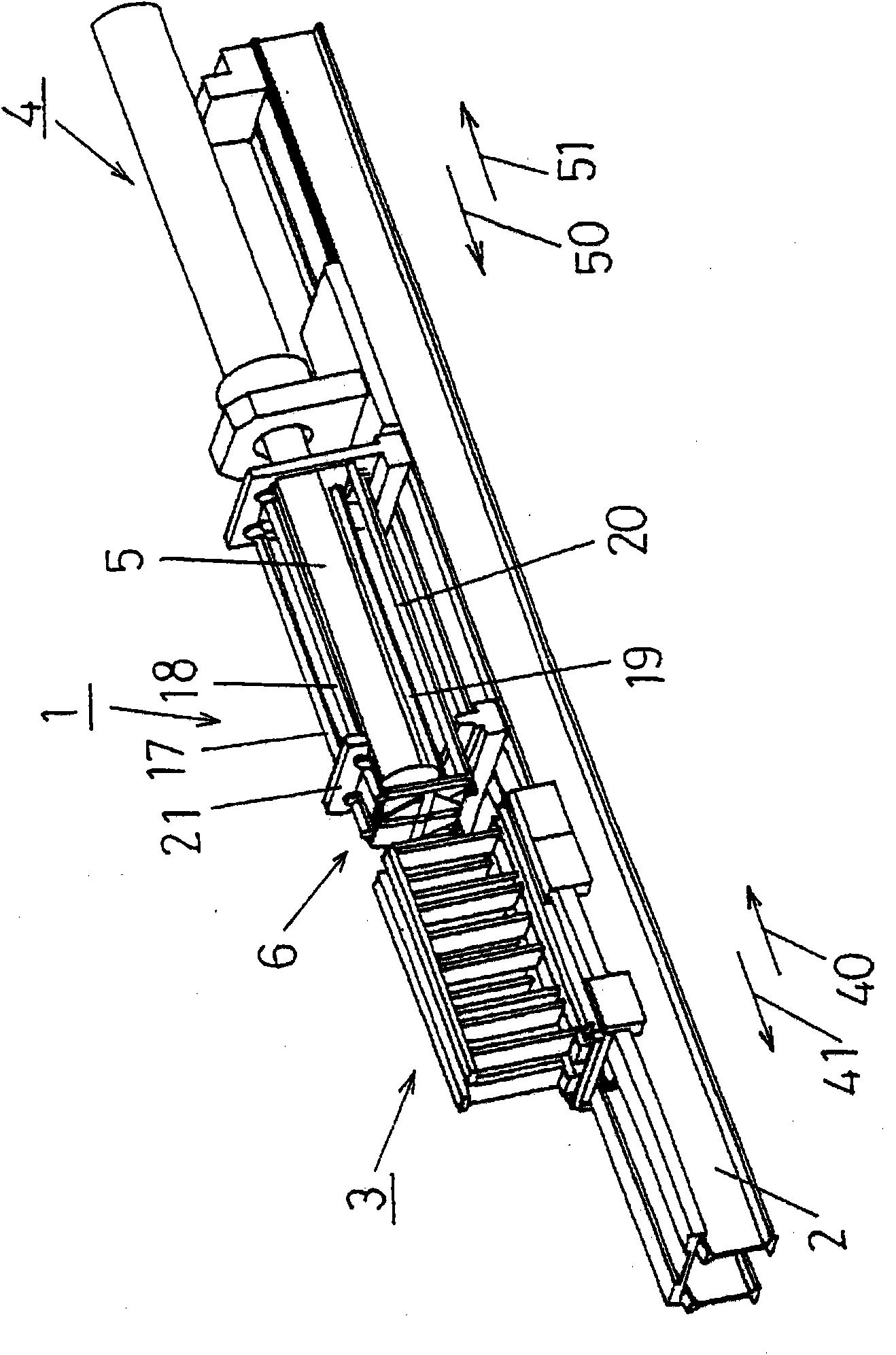

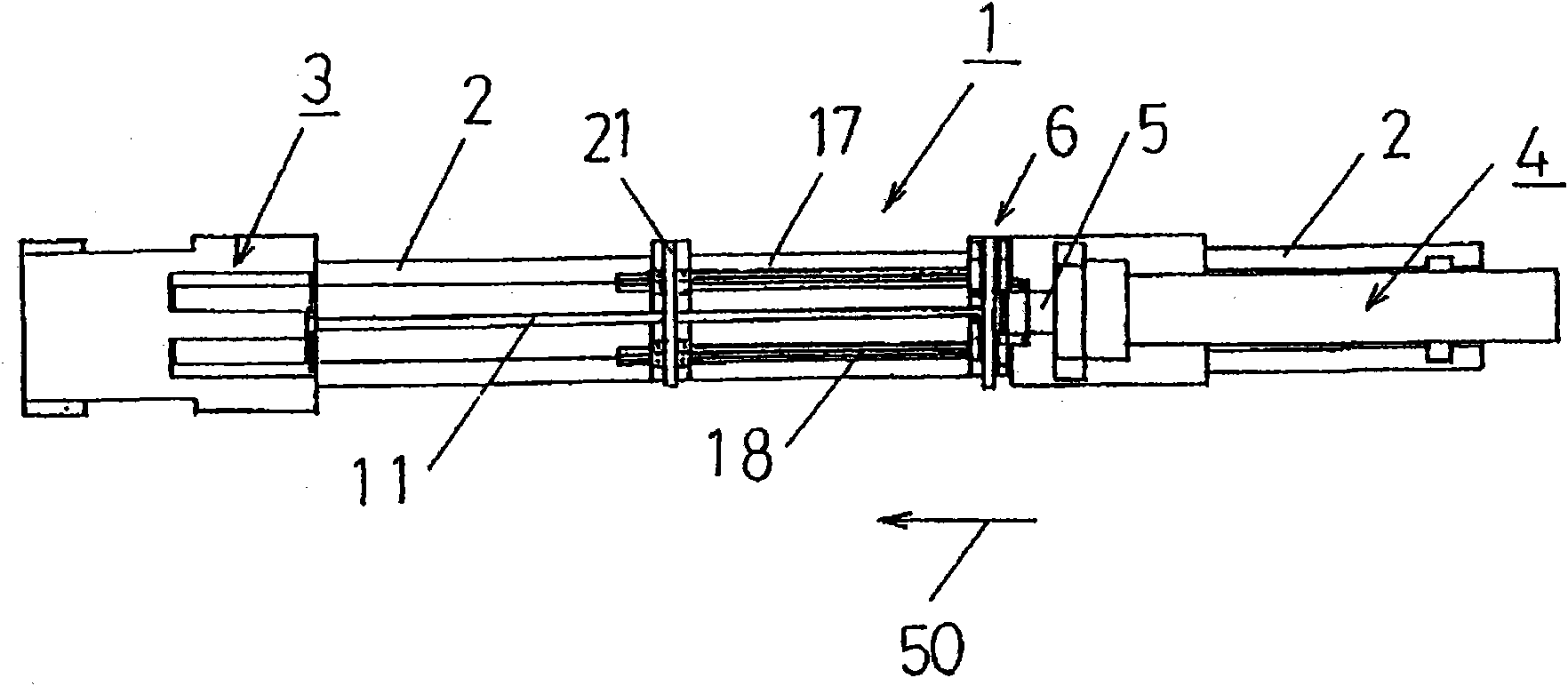

[0073] Next, preferred embodiments of the present invention will be described with reference to the drawings.

[0074] In the forming apparatus 1 , a driving device 4 and a forming stand 3 are arranged to face each other on a base 2 . The forming stand 3 is provided with at least one pair of forming rolls or a pair of forming dies.

[0075] The driving device 4 is provided with a driving rod 5 . The drive rod 5 is driven by a drive source not shown, and moves forward and backward in a direction (arrow 50 ) approaching the forming stand 3 and a direction away (arrow 51 ) from the forming stand 3 . The driving rod 5 is provided with a to-be-formed material support mechanism 6 at the front end on the side of the forming stand 3 .

[0076] In this forming apparatus 1, a material to be formed 11 such as a metal pipe is pressed by a material to be formed supporting mechanism 6 ( image 3 ), on the side of the driving device 4 ( image 3 The right end in the center), the driving ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap