Clothes rack, mold for same and method for manufacturing same

A manufacturing method and technology for hangers, which are applied in the directions of hangers, clothing, and applications, can solve the problems of shrinkage marks, large warpage deformation, waste of materials, etc., and achieve the effects of reducing scrap rate, small warpage deformation, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

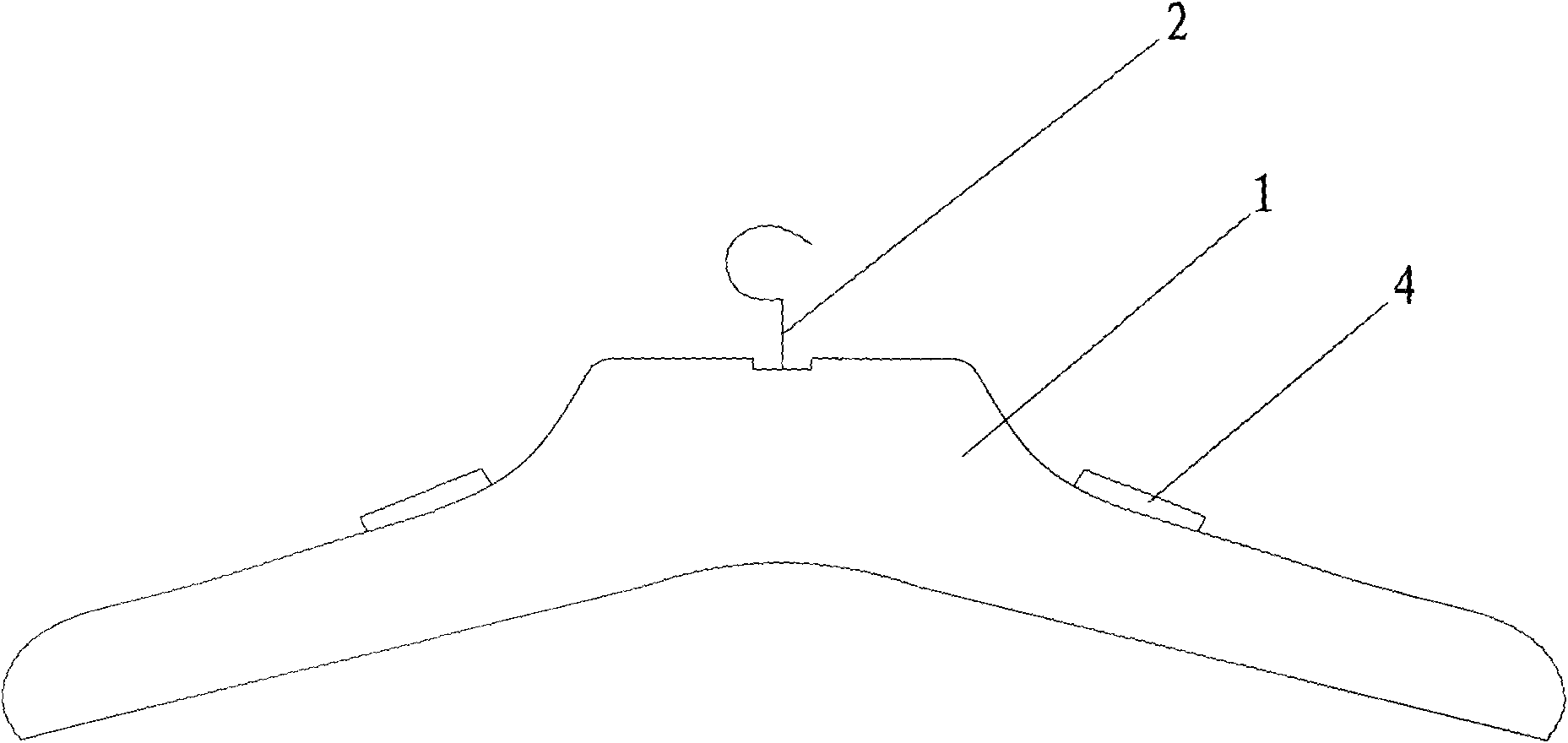

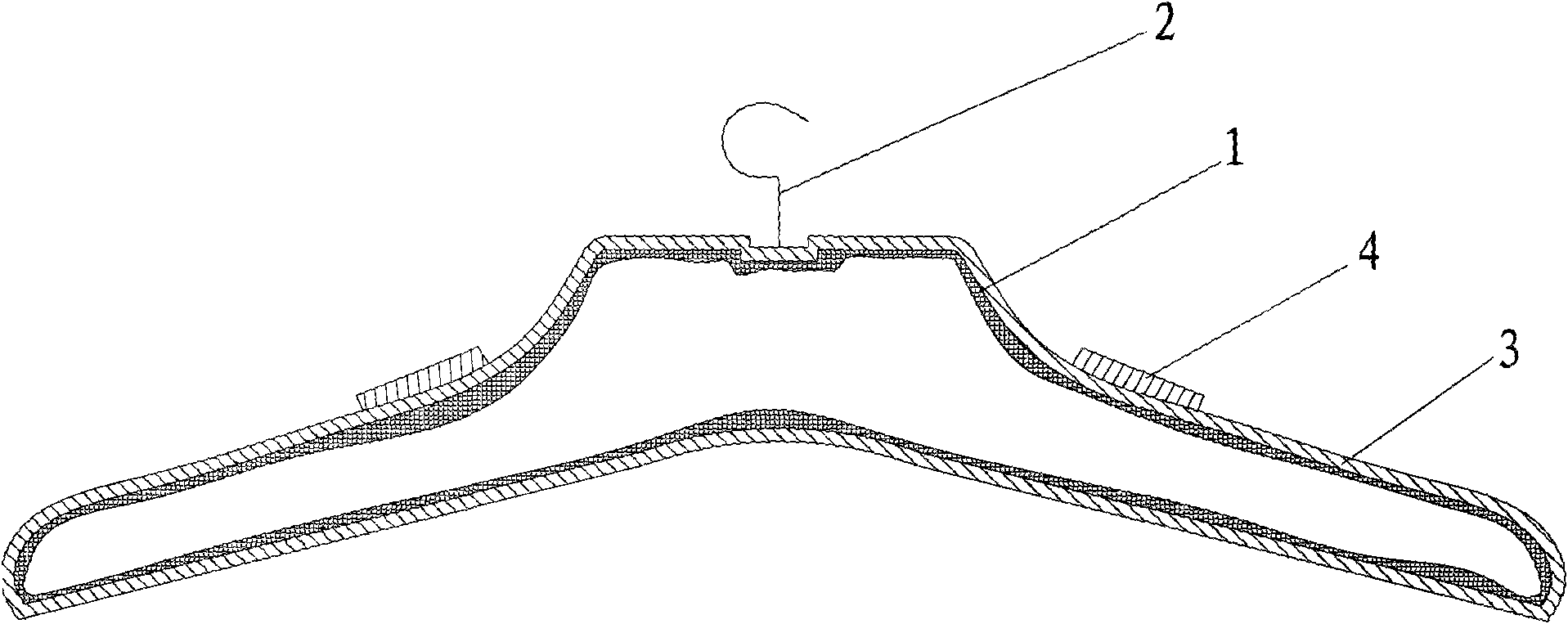

[0026] Such as figure 1 , figure 2 The shown clothes hanger includes a plastic clothes hanger body 1 and a hook 2 arranged on the clothes hanger body, and the inside of the clothes hanger body 1 is hollow. The hanger body 1 is covered with a decorative layer 3 . The shoulder position of the hanger body is provided with an anti-skid component 4 . The anti-slip component can be an anti-slip mat or an anti-slip strip. The hanger body 1 is injection molded from engineering plastics, preferably made of ABS or PS.

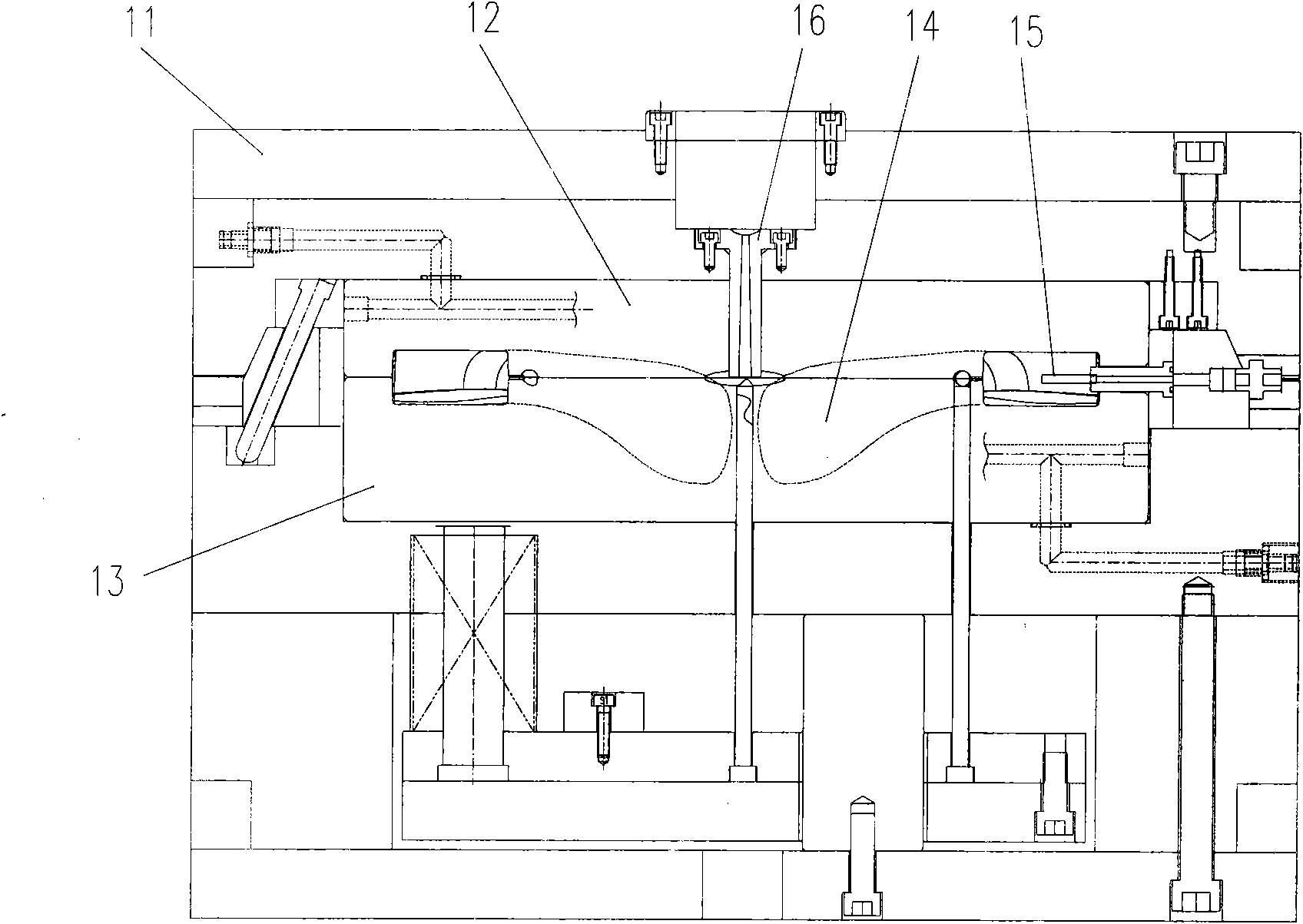

[0027] Such as image 3 and Figure 4 The mold of the shown clothes hanger comprises mold frame 11, nozzle 16, the clothes hanger mold cavity 14 that front mold 12 and rear mold 13 constitute, and mold cavity 14 is provided with blowing needle 15. There is a plastic melt collection cavity 19 outside the mold cavity, and a diversion groove 17 communicates the plastic melt collection cavity 19 with the mold cavity 14, and the diversion groove 17 is away from the blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com