Welding process for broken 34CrNi3Mo electro-hydraulic hammer lever

A welding process and electro-hydraulic hammer technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of long time consumption, waste of money, high cost of new hammer rods, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment is suitable for replacing a broken hammer shaft with a base material, that is, a 34CrNi3Mo base material matching the section of the hammer shaft is selected, and the diameter of the base material is slightly larger than the diameter of the hammer shaft. Welded to make a new hammer shaft.

[0027] Its process steps are as follows:

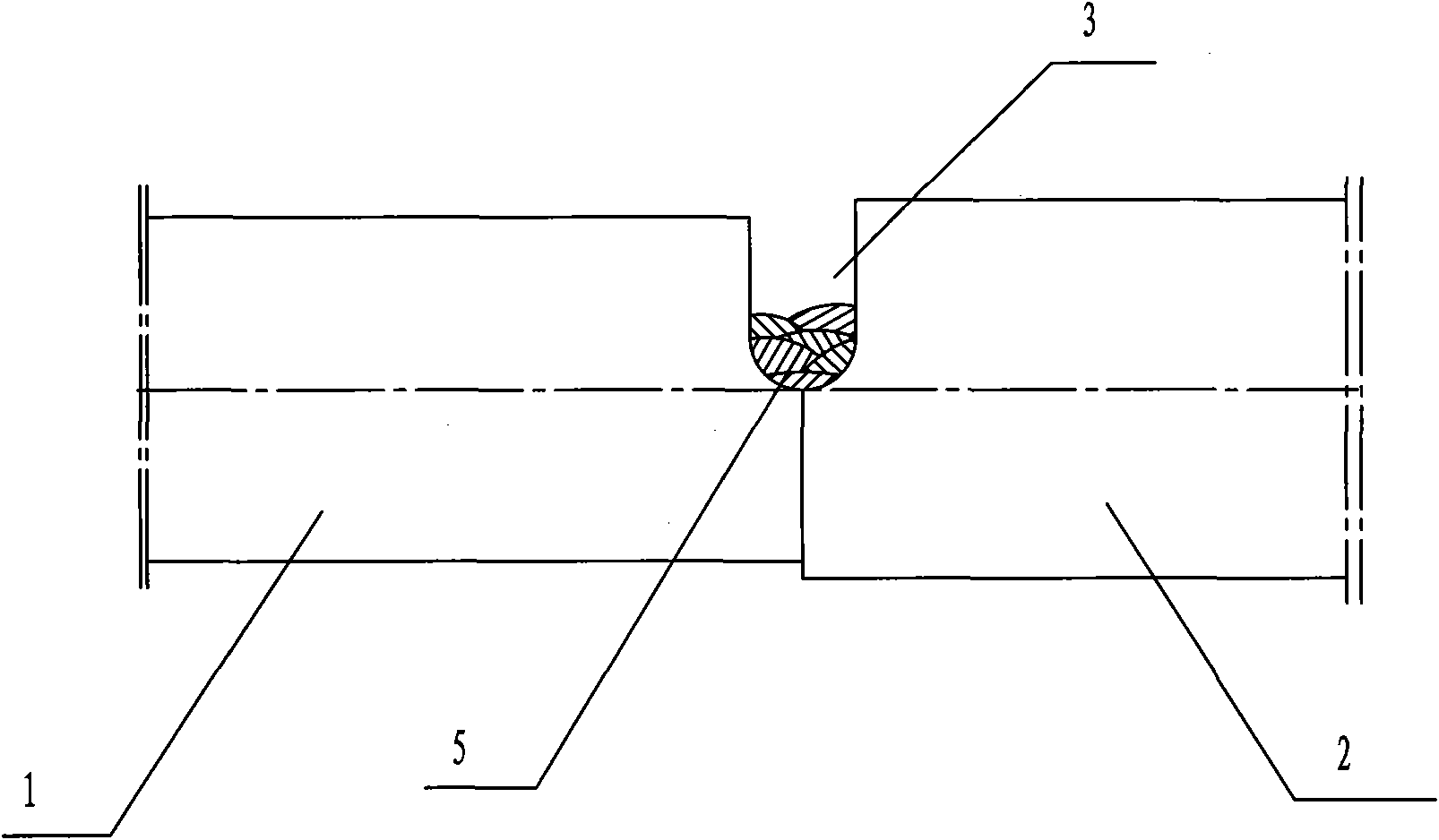

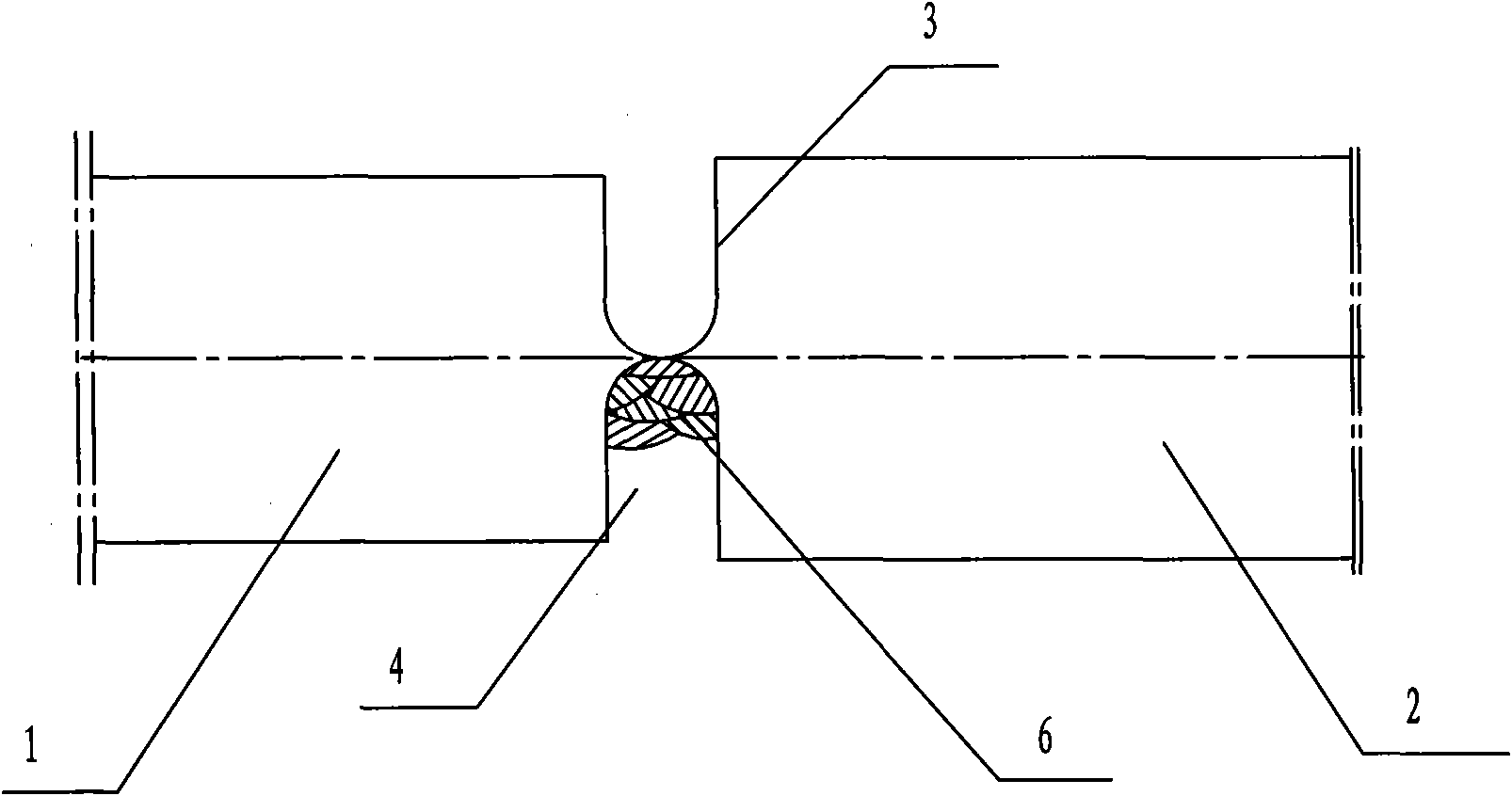

[0028] (1), the broken hammer shaft fracture section 1 is docked with a piece of 34CrNi3Mo base material 2 matching the section;

[0029] (2), at the hammer shaft fracture section 1 described in step (1) and the 34CrNi3Mo base material 2 interface, open the U-shaped groove 3 on one side with the gas cutting mode, (because the base material is carried out very suitable when adopting gas cutting The preheating temperature does not need to be repeated, and the method is simple) The bottom end of the U-shaped groove 3 reaches the horizontal centerline position between the fractured section of the hammer rod and the base material...

Embodiment 2

[0036] This embodiment is suitable for directly welding together the broken two-section hammer shank to restore the hammer shank.

[0037] Its specific process steps are as follows:

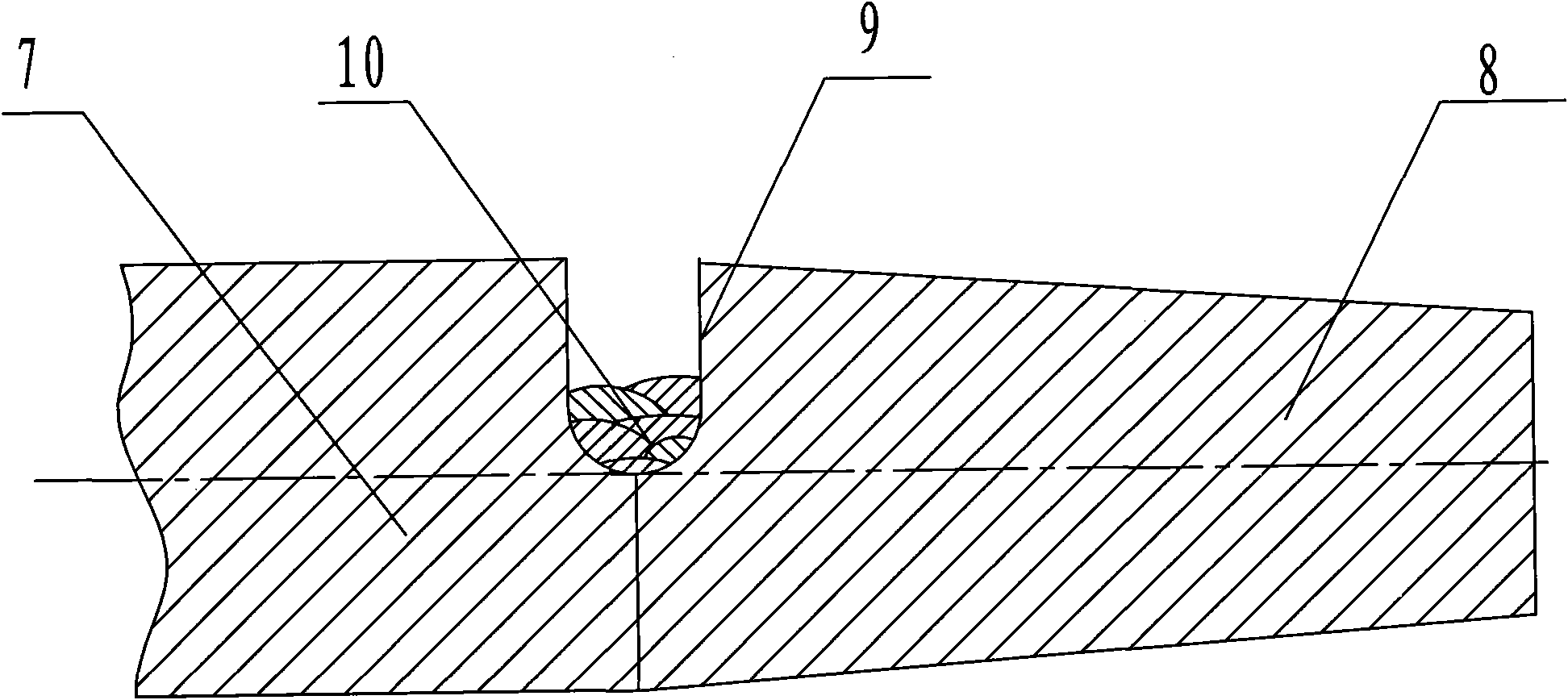

[0038] (1), butt joint placement of the broken two sections of hammer rod fracture sections 7 and 8;

[0039] (2) At the interface of the fractured section of the two hammer shafts, a U-shaped groove 9 is opened on one side by means of gas cutting, and the bottom end of the U-shaped groove 9 reaches the horizontal centerline of the hammer shaft. Add welding material 10, welding material 10 is J107Cr material, and use multi-layer and multi-pass welding for 5-7 times;

[0040] (3), U-shaped groove 11 is opened on the other side of the two hammer rod fracture sections processed in step (2), and U-shaped groove 11 is opposite to the bottom end of U-shaped groove 9 in step (2). Add welding consumables 12 to the groove 11, and the welding consumables 12 is J107Cr material, which is welded in a multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com