Reference unifying installation process of large flexible gearbox

An installation process and gearbox technology, applied in the field of unified installation process of large-scale flexible gearbox benchmarks, can solve the problems of lack of uniformity, affecting the normal meshing of gears, affecting the reliability of gearbox use, etc., to achieve stability and improve use. Reliable, easy-to-achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

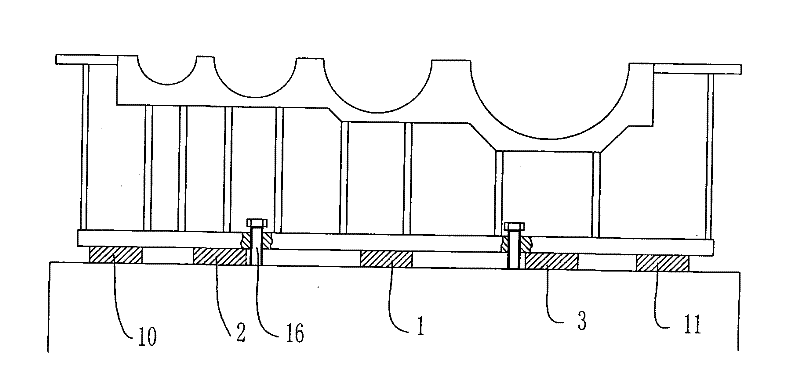

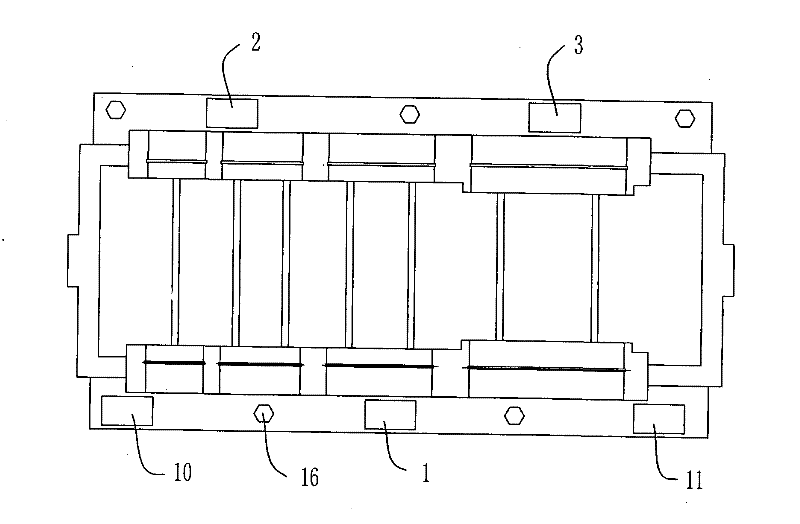

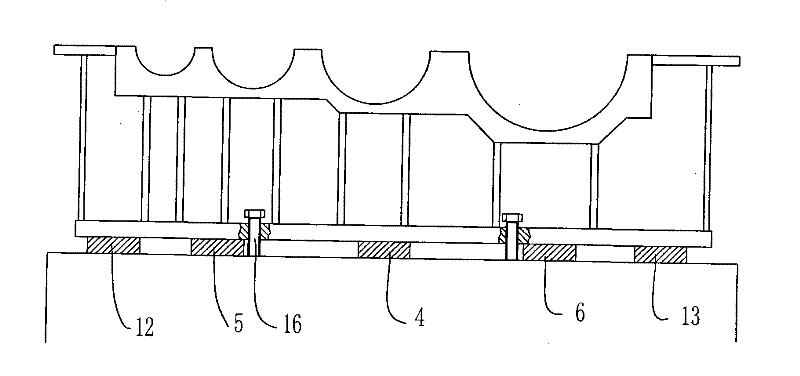

[0023] The process steps of the method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] See Figure 1 to Figure 6 : The benchmark unified installation process of the large flexible gearbox shown includes the following steps:

[0025] (A) Processing stage: ① first place the first block 1, the second block 2, and the third block 3 on the machine tool workbench, three equal-height blocks, ② hang the box on the machine tool workbench, And mark the supporting positions of the first pad 1, the second pad 2, and the third pad 3 on the box installation datum plane, ③ place the adjustment pad between the box installation datum plane and the machine table, and use Use a feeler gauge to check and adjust the gap between the pads and the installation reference surface of the box, so that the box can keep in good contact with these pads in a free state. ④In the first pad 1, the second pad 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com