Permanent-magnet synchronous engraving and milling electric spindle adopting internal cooling for shaft core

A technology of permanent magnet synchronization and electric spindle, which is applied in the direction of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc. It can solve the problems of long time for manual polishing, thermal elongation of the spindle and insufficient fineness, etc., and achieve reliable The effect of machining target, stable bearing temperature and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Shown in the accompanying drawings, the present invention is further described:

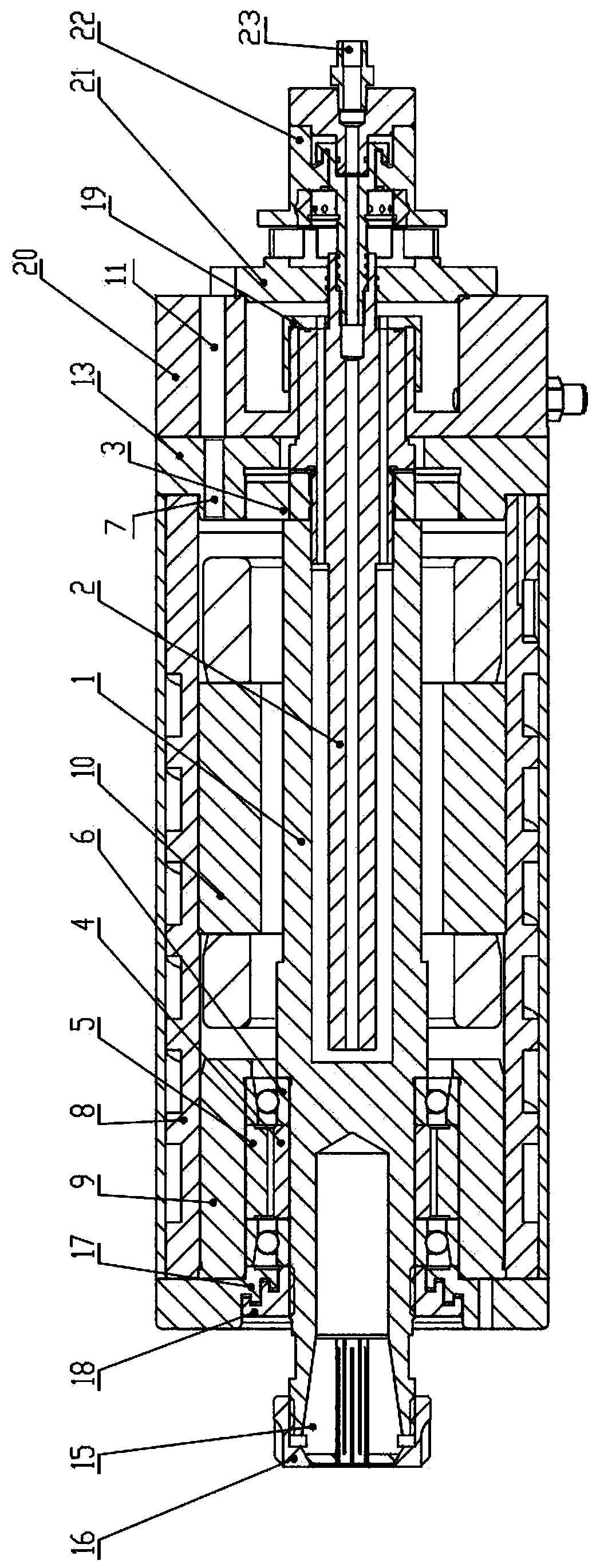

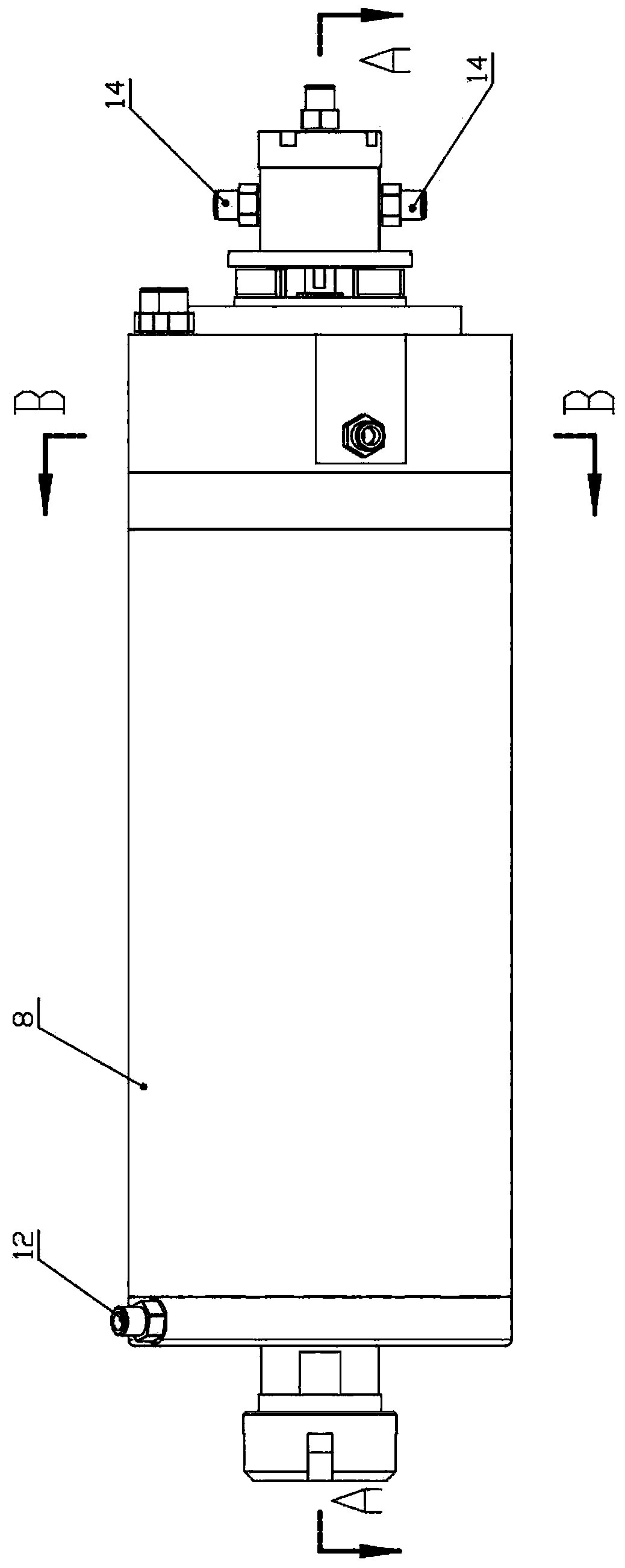

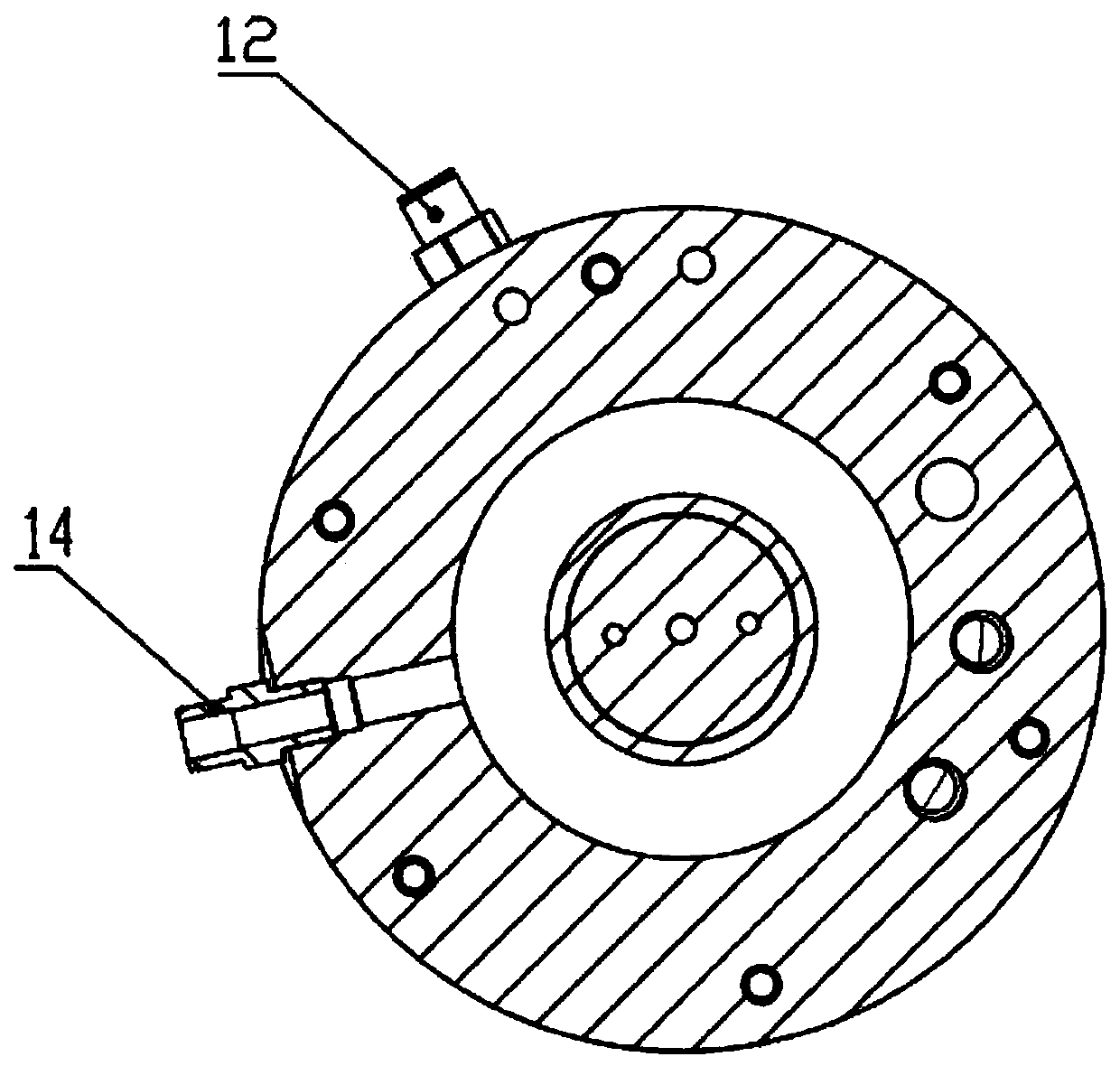

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, among them, figure 1 figure 2 A-A sectional view of the section, image 3 yes figure 2 The B-B cross-sectional view, Figure 4 is the end view of the electric spindle. The technical purpose of the present invention is to overcome the problems that the thermal elongation of the spindle core of the engraving and milling electric spindle is not well controlled and the precision of the spindle fluctuates with temperature changes. The specific technical solution is as follows: the design is a built-in rare earth permanent magnet synchronous high-speed motor-driven spindle, including a rotatable spindle core 1, a liquid splitting shaft 2 for cooling the spindle core 1, and a support for the spindle core 1. The rear bearing 3 and the front bearing 6, the water jacket housing 8 for cooling the stator 10 and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com