Method for processing bearing support

A processing method and technology of bearing housings, which are applied in the processing field of bearing housings or other similar products, can solve problems such as the reduction of the input-output ratio of bearing housings, the influence of the accuracy of bearing housings, and the increase in labor intensity of operators, so as to reduce the The effect of input-output ratio, reduction of skill requirements and operating intensity, and saving of equipment input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

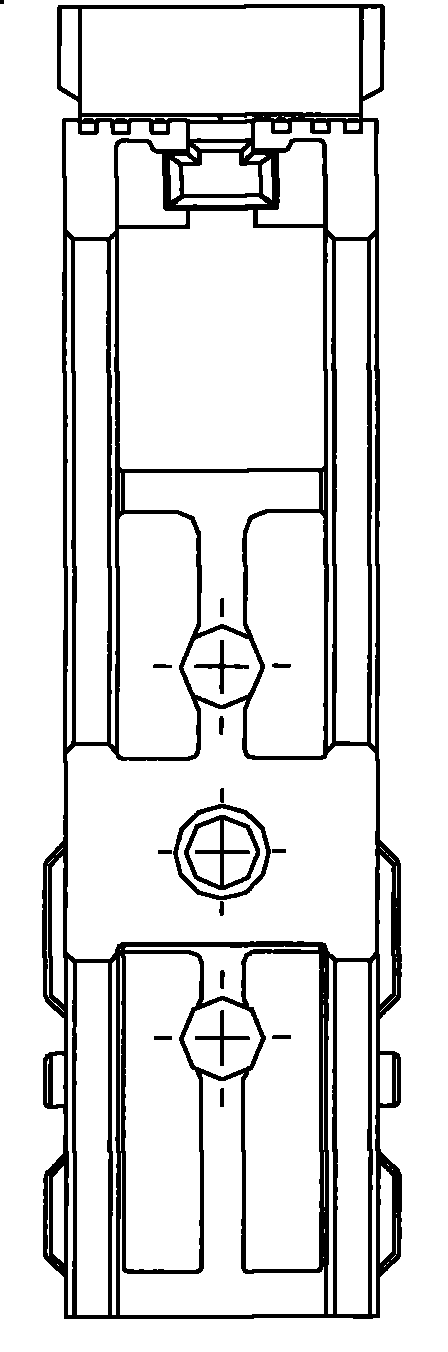

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

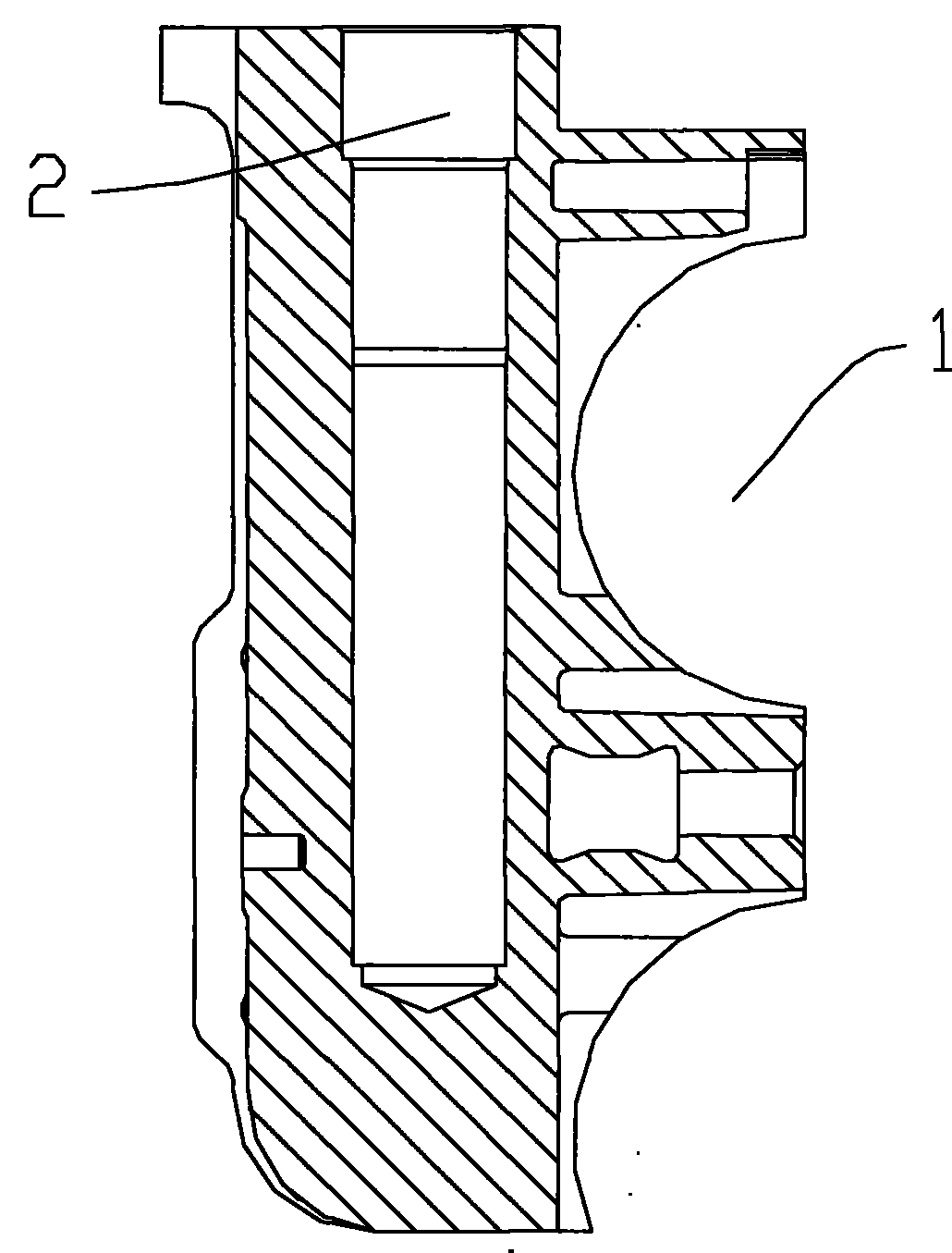

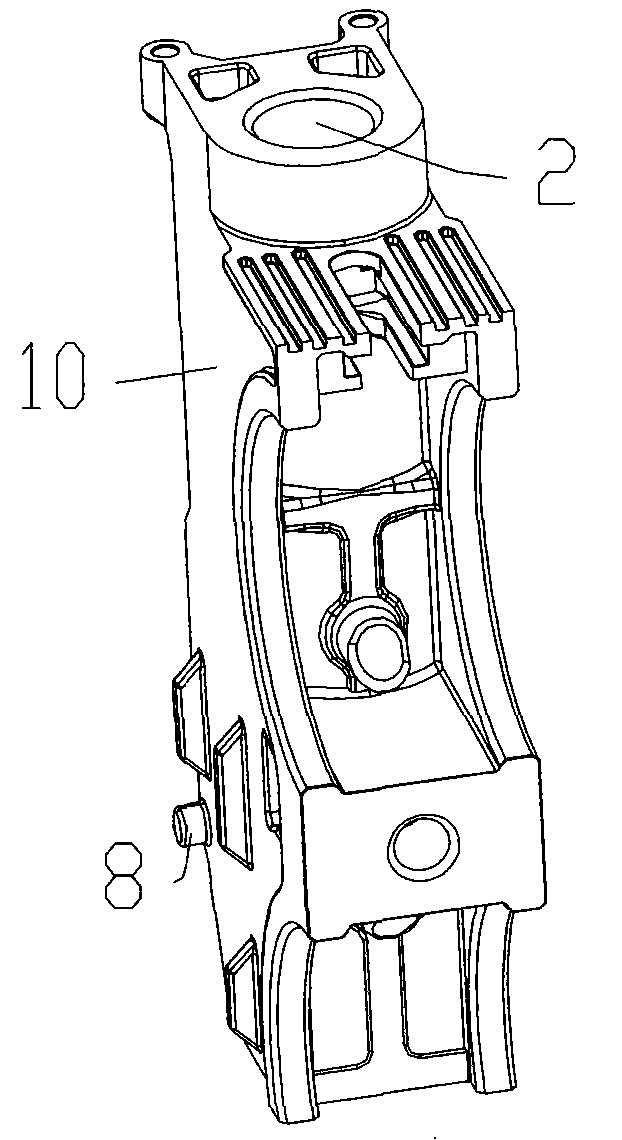

[0021] The machining tooling of the four-axis machining center consists of three major systems, including a positioning system, a locking mechanism and a rotation system. The positioning system is composed of a wedge-shaped pressing block 3, a lateral positioning column 4 and a positive positioning column 5; the locking mechanism is composed of three positive supports 6 forming a triangle, a driving cylinder 7, a switch and a pressure plate (not shown); the rotation system It is composed of a bridge plate (the mounting seat of the positioning system and the locking mechanism) 9 and an L-shaped block, and is connected with the fourth axis of the machining center through positioning pins and fastening with bolts. A positive positioning column 5 and three positive supports 6 are also fixed on the bridge plate 9 .

[0022] The wedge-shaped pressing block 3 and the lateral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com