Scale error compensation strategy for rotary type strapdown inertial navigation gyroscope

A scale error, strapdown inertial navigation technology, applied in the field of inertial navigation, can solve the problems of positive and negative asymmetry, optical gyro scale factor error, inertial element scale factor error, etc., to achieve the effect of improving accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

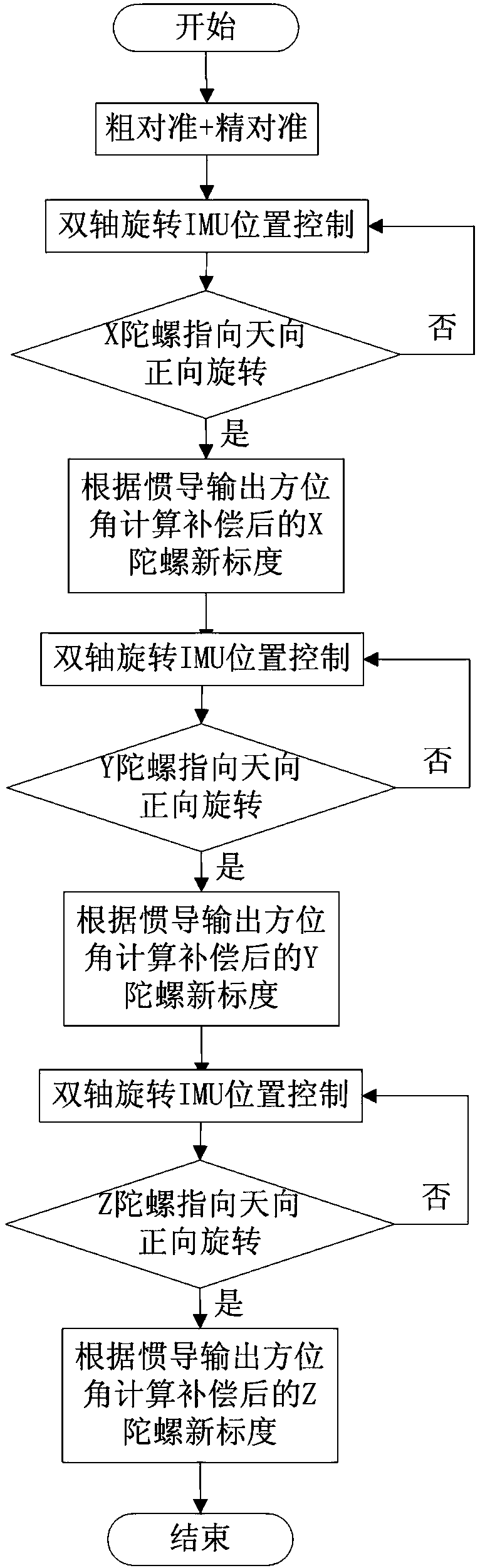

[0024] A scale error compensation strategy for a rotary strapdown inertial navigation gyro, such as figure 1 shown, including the following steps:

[0025] Step 1. The inertial navigation equipment is powered on, initialized and roughly aligned.

[0026] (1) The inertial navigation equipment is powered on, and the two rotating shafts rotate to their respective zero positions according to the preset control command;

[0027] (2) Staple the initial position, complete the rough alignment process according to the preset rough alignment scheme, and obtain the rough alignment result.

[0028] Step 2, two-axis rotation modulation fine alignment.

[0029] The inertial navigation enters the fine alignment stage, and begins to perform periodic rotation with a predetermined plan. After the fine alignment is completed, the inertial navigation enters the nav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com