Equipment and method for producing concrete tubular pile

A technology for concrete pipe piles and concrete is applied in the field of equipment for producing concrete pipe piles, which can solve problems such as unqualified products, and achieve the effects of reducing equipment failures, reducing wear and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

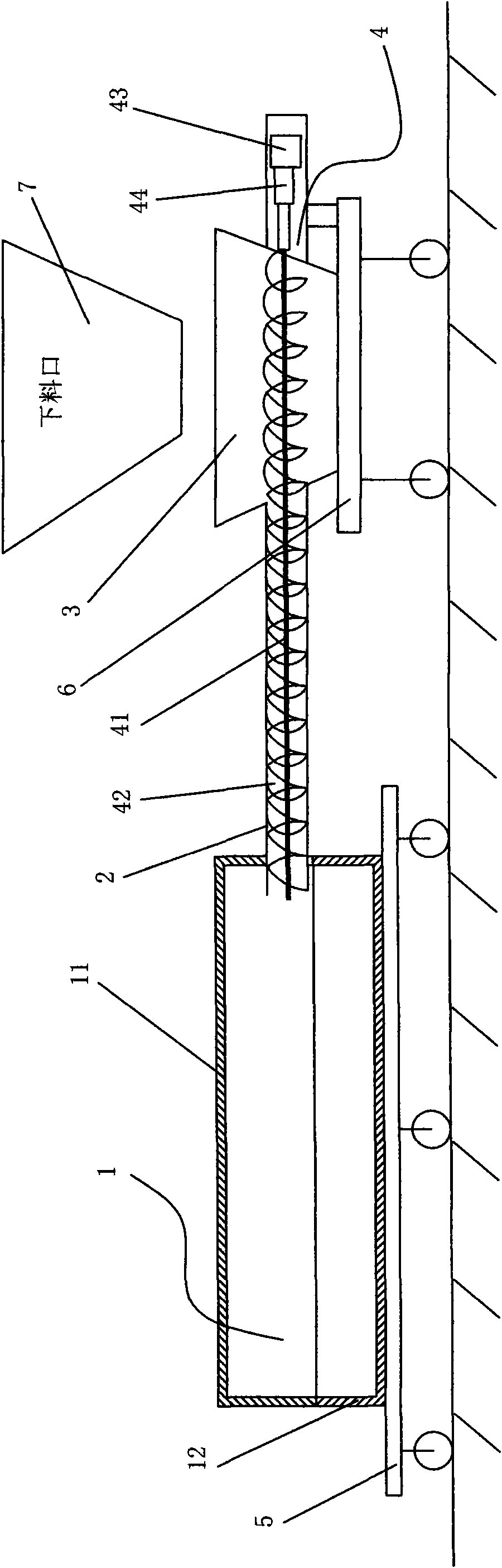

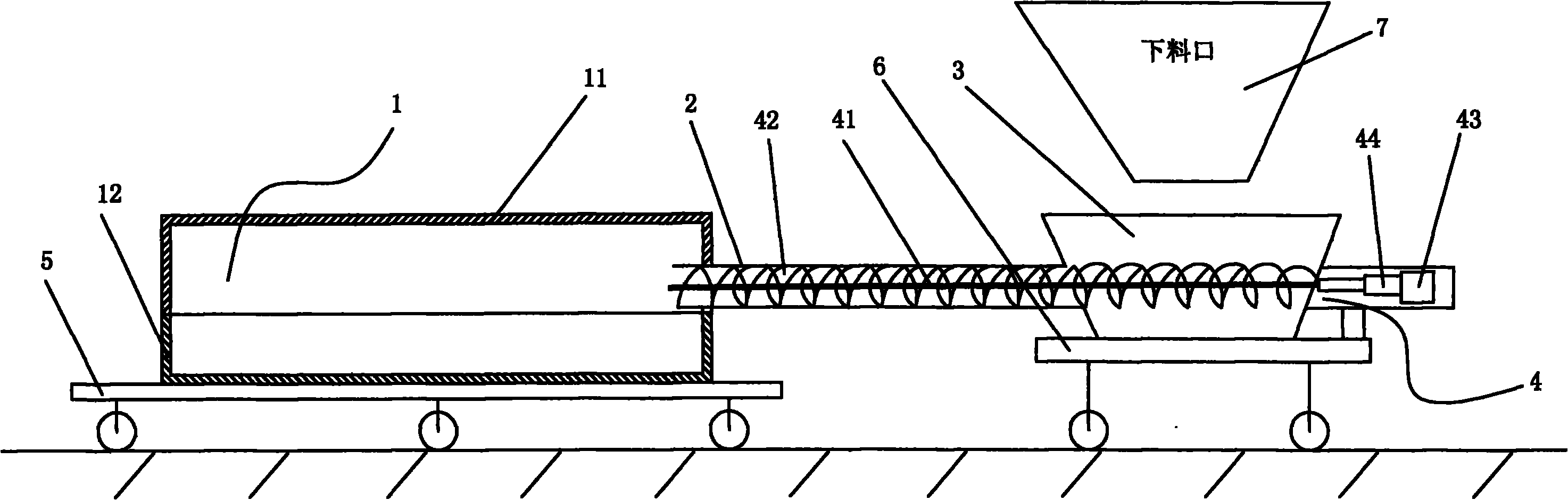

[0040] In the first embodiment, the pipe pile mold 1 is set on a flat car 5, and the material conveying steel pipe 2 is fixedly set. Moving the flat car 5 can make the pipe pile mold 1 and the material conveying steel pipe 2 move relatively.

[0041] In the second embodiment, the pipe pile mold 1 is fixedly arranged, and the material conveying steel pipe 2 is arranged on a small flat car 6 . Specifically, the material conveying steel pipe 2 is fixedly connected to the feed hopper 3 , and the feed hopper 3 is fixedly connected to the flat car 6 . Moving the small flat car 6 can make the pipe pile mold 1 and the material delivery steel pipe 2 move relatively.

[0042] In the third embodiment, the pipe pile mold 1 is arranged on a flat car 5; the material conveying steel pipe 2 is arranged on a small flat car 6, specifically, the material conveying steel pipe 2 is fixedly connected to the On the feed hopper 3, the feed hopper 3 is fixedly connected with the small flat car 6. M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com