Lower bracket assembly of car radiator

A radiator and bracket technology, which is applied in the field of the lower bracket assembly of the car radiator, can solve the problems of poor rigidity of the radiator installation point, unsteady installation of the radiator, difficult operation, etc., so as to improve the accuracy and prevent unstable installation. or abnormal noise phenomenon, the effect of labor-saving operation of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

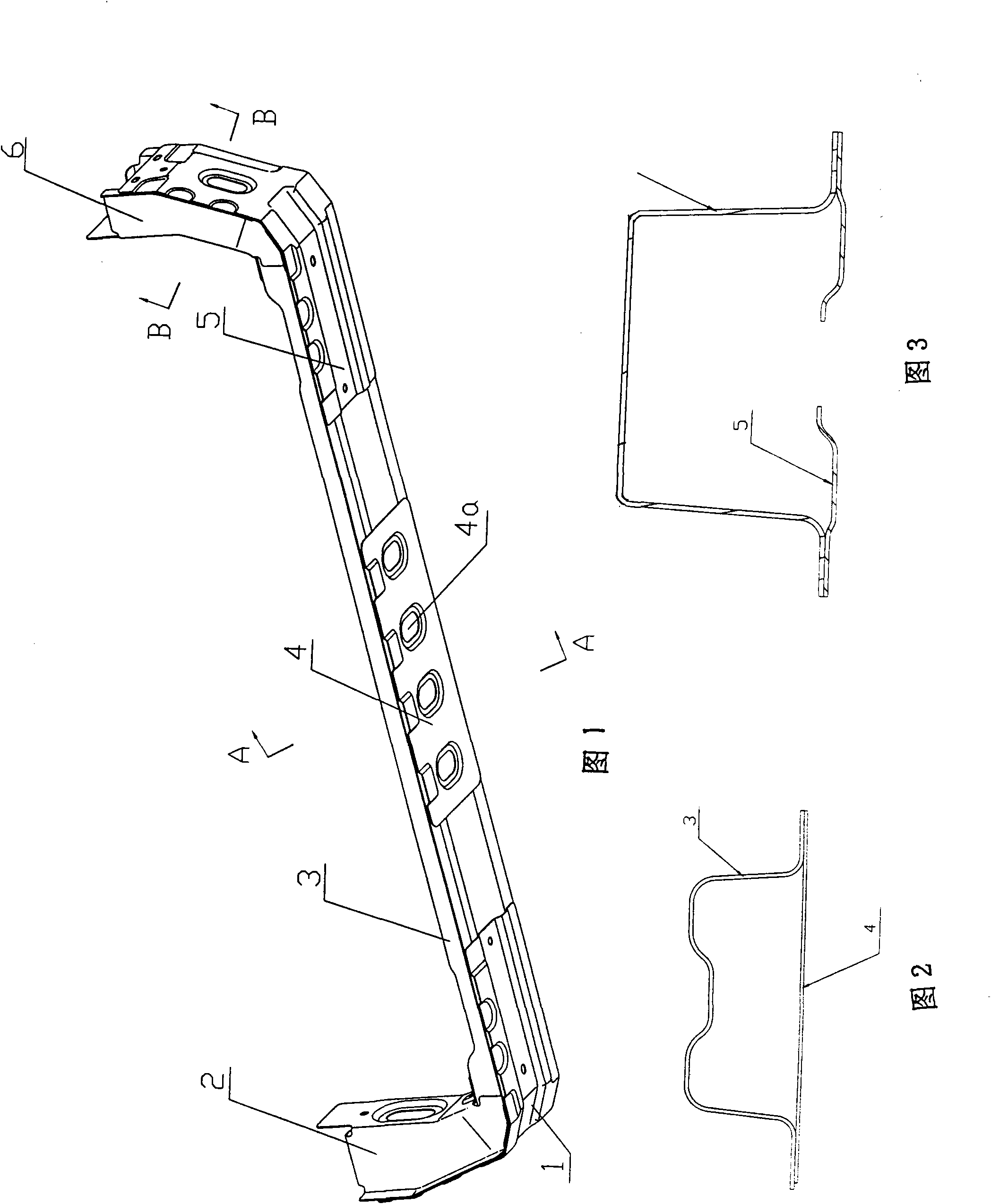

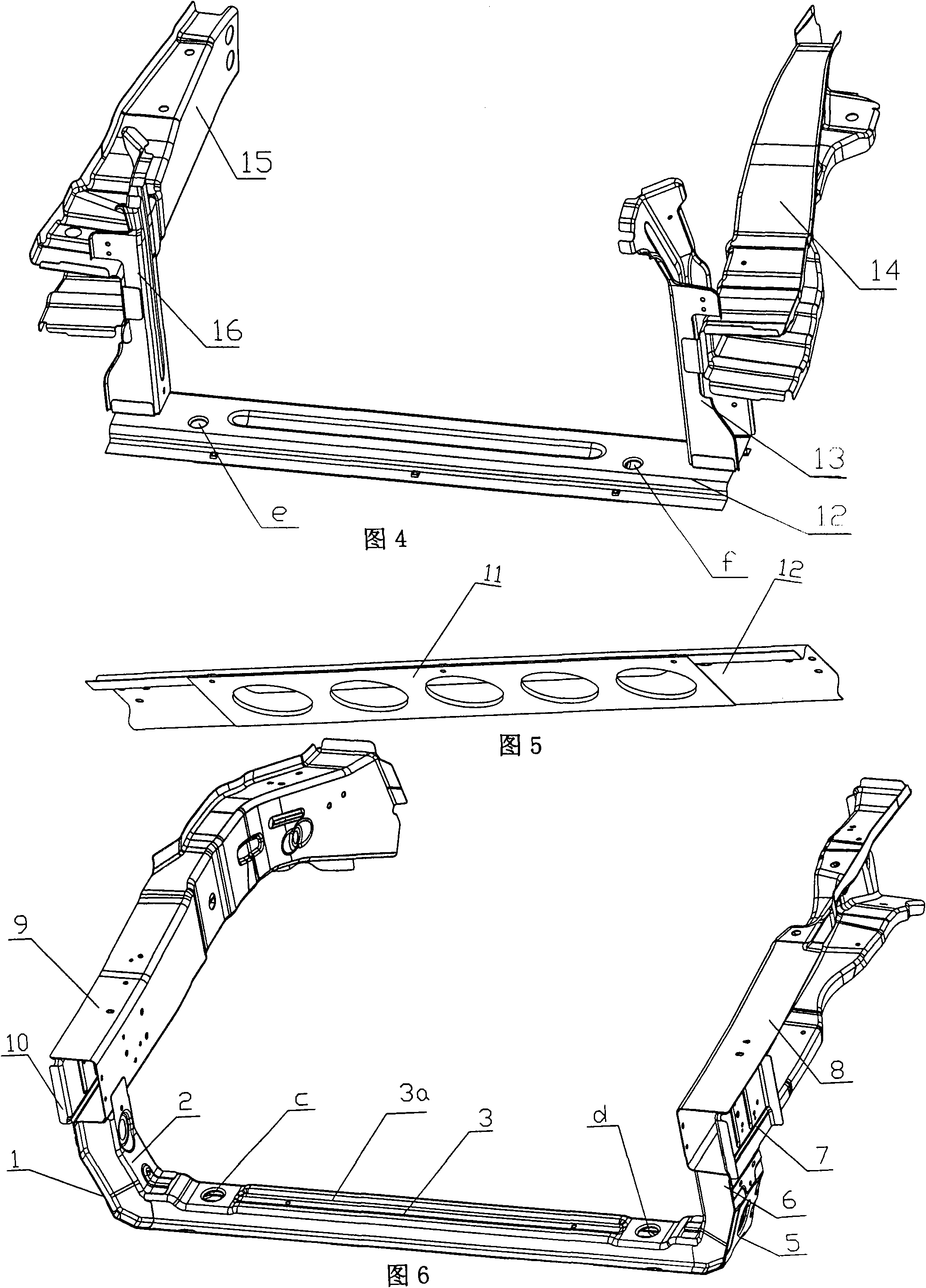

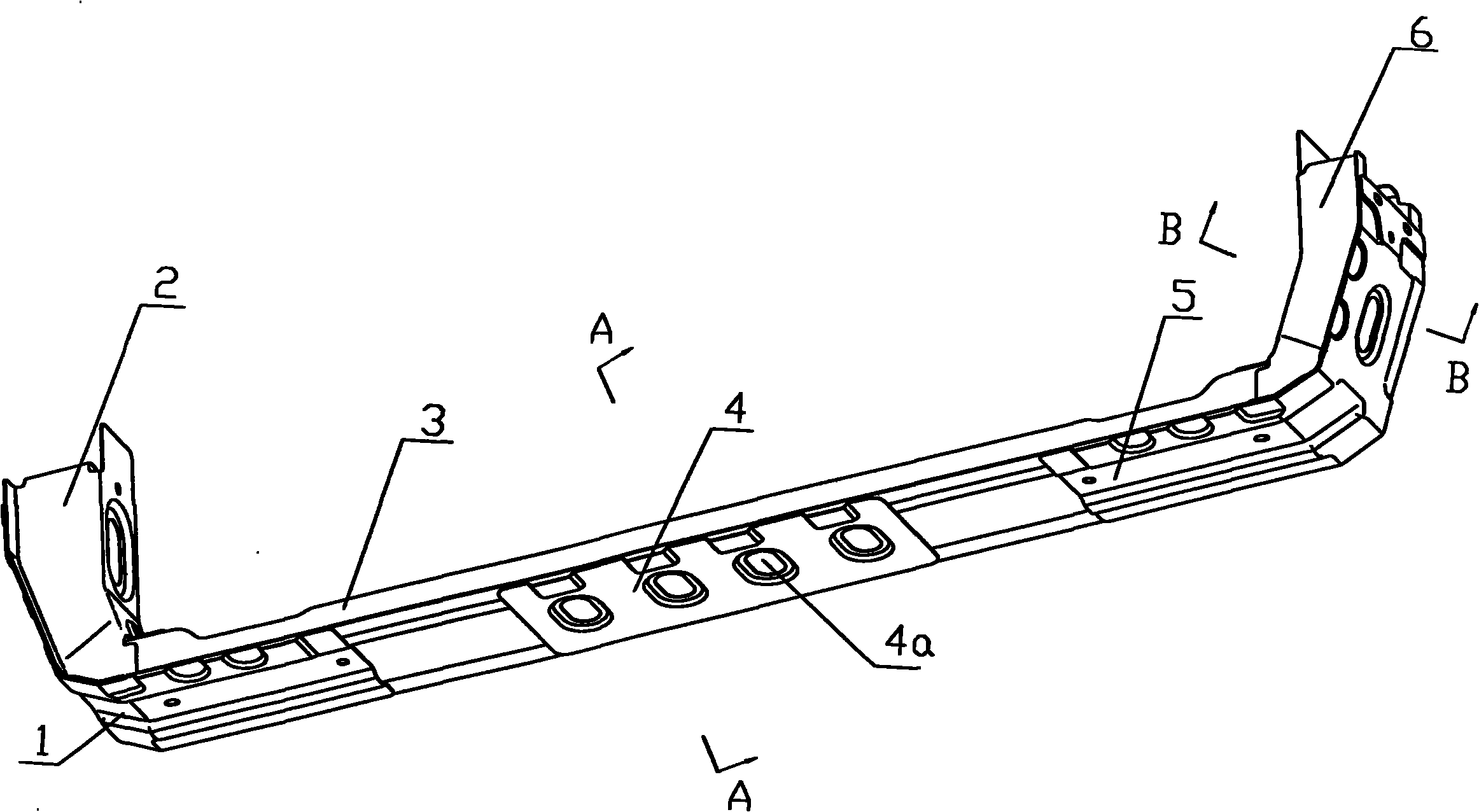

[0018] see figure 1 , figure 2 and image 3 A car radiator lower bracket assembly shown includes a bracket body 3, and two flange holes c, d are arranged on the bracket body, and the two flange holes are mounting points under the radiator; The bracket body 3 is provided with two reinforcing ribs 3a; the cross section of the bracket body 3 is in the shape of "Ji", and a middle reinforcement 4 with 4 weight-reducing holes 4a is connected under the bracket body; The left end of 3 is connected with an upwardly bent left connector outer plate 2, the cross-section of the left connector outer plate is in the shape of a "several" shape, and a left connector inner plate 1 is connected to its left side; A right connector outer plate 6 bent upwards is arranged, and the cross section of this right connector outer plate becomes a "several" shape, and a right connector inner plate 5 is connected on its right side. When welding, the bracket body 3 and the middle reinforcement 4 are spot-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com