Method for treating ammonia-containing waste water from crushed coal pressure gasification

A technology of pressurized gasification and treatment of crushed coal, which is applied in degassed water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problem of poor deamination effect and long process flow, etc. Problems, to achieve the effect of simple process, reduce environmental pollution, and large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The crushed coal pressurized gasification wastewater after removing suspended solids, tar and some light oils enters the device of the present invention. The wastewater volume is 50 tons per hour, the temperature is 20-60°C, and it contains: free ammonia 7040mg / L, total ammonia 7740mg / L, phenol 50mg / L, carbon dioxide 420mg / L, oil 1mg / L.

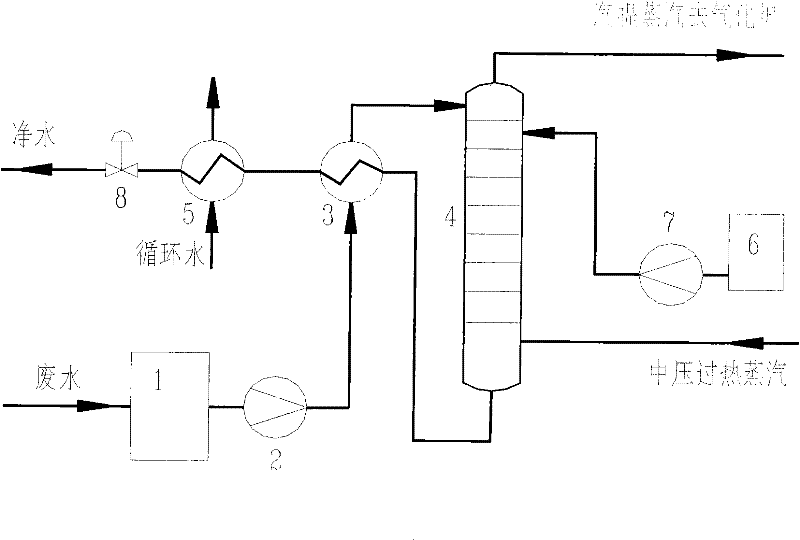

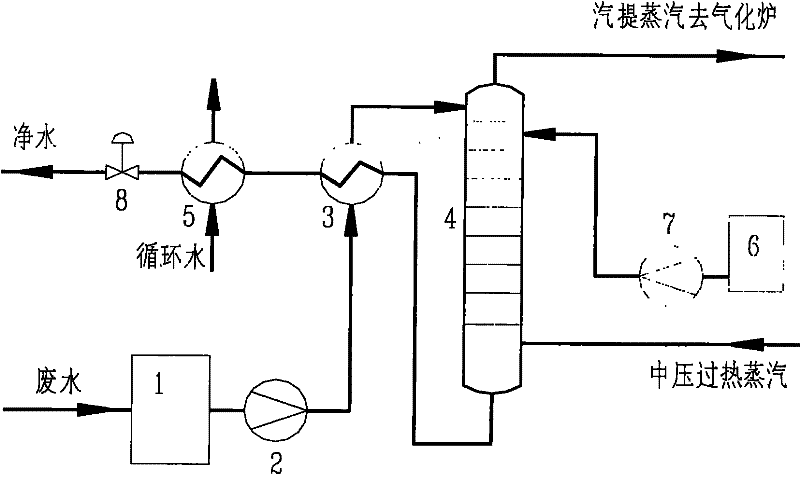

[0022] After the ammonia-containing wastewater is pressurized to 3.8 MPa by the pressurizing pump 2, it exchanges heat with the purified water from the bottom of the stripper 4 in the inlet and outlet water heat exchanger 3, and is heated to 210°C from the upper part of the stripper 4. Enter the stripping tower, and at the same time, use an alkali pump to add a sodium hydroxide solution with a weight concentration of 5%, a temperature of 60°C, and a flow rate of 2.8t / h (5.6% of the weight of ammonia-containing wastewater) at the top of the stripper 4. And mixed with ammonia-containing wastewater, running from top to bottom. The medium-p...

Embodiment 2

[0025] The crushed coal pressurized gasification wastewater after removing suspended solids, tar and some light oil, enters the device of the present invention. The wastewater volume is 100 tons per hour, the temperature is 20-60°C, and it contains: free ammonia 9800mg / L , Total ammonia 11200mg / L, phenol 30mg / L, carbon dioxide 470mg / L, oil 1mg / L.

[0026] After the ammonia-containing wastewater is pressurized to 3.8 MPa by the pressurizing pump 2, it exchanges heat with the purified water from the bottom of the stripper 4 in the inlet and outlet water heat exchanger 3, and is heated to 210°C from the upper part of the stripper 4. Enter the stripping tower, and at the same time, use an alkali pump to add a sodium hydroxide solution with a weight concentration of 10%, a temperature of 30°C, and a flow rate of 6.2t / h (6.2% by weight of ammonia-containing wastewater) at the top of the stripper 4. And mixed with ammonia-containing wastewater, running from top to bottom, 3.8MPa, 440℃, ...

Embodiment 3

[0029] The crushed coal pressurized gasification wastewater after removing suspended solids, tar and some light oil, enters the device of the present invention. The wastewater volume is 80 tons per hour, the temperature is 20-60°C, and it contains: 7900mg / L of free ammonia , Total ammonia 8300mg / L, phenol 40mg / L, carbon dioxide 410mg / L, oil 1mg / L.

[0030] After the ammonia-containing wastewater is pressurized to 3.6MPa by the pressurizing pump 2, it exchanges heat with the purified water from the bottom of the stripper 4 in the inlet and outlet water heat exchanger 3, and is heated to 210°C from the upper part of the stripper 4. Enter the stripper, and at the same time, use an alkali pump to add potassium hydroxide solution (6.3% by weight of ammonia-containing wastewater) with a weight concentration of 7%, a temperature of 45°C, and a flow rate of 5.0t / h at the top of the stripper 4, And mixed with ammonia-containing wastewater, running from top to bottom, 3.2MPa, 380℃, flow ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com