Rubber-asphalt reaction kettle

A technology of rubber asphalt and reactor, which is applied in the direction of building components, building insulation materials, construction, etc., can solve the problems of inability to correctly guide the production and application of waste tire rubber asphalt, difficulty in making qualified rubber asphalt, and insufficient mixing reaction. Achieve the effect of simple structure, precise temperature control and full reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

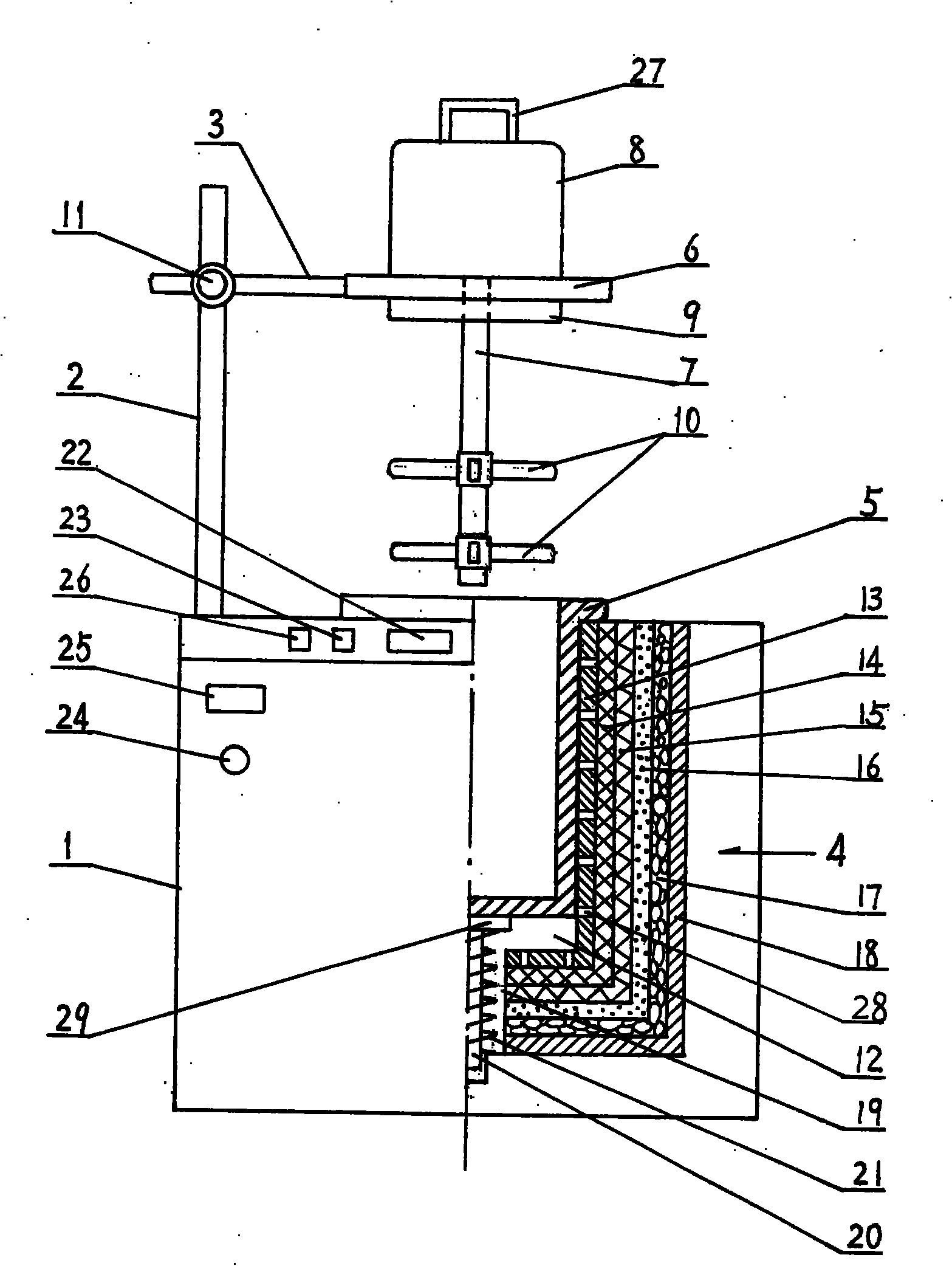

[0026] Such as figure 1 As shown, the present invention includes a kettle body 1 and a power supply circuit and a control circuit arranged in the kettle body 1, a heating and heat preservation device 4 is also arranged in the kettle body 1, and a mixing reaction tank 5 is placed in the heating and heat preservation device 4 , the top of the mixing reaction tank 5 is provided with a connection plate 6 and a stirring shaft 7 positioned below the connection plate 6, the top of the connection plate 6 is vertically provided with a motor 8, and the bottom of the connection plate 6 is provided with a mixing reaction tank The airtight cover 9 corresponding to the port of 5, the center of described airtight cover 9 and connecting plate 6 is provided with through hole oppositely, the upper end of agitating shaft 7 passes through described through hole and is connected with the main shaft of motor 8, is arranged on agitating shaft 7 There are two groups of stirring blades 10, the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com