Retaining wall structure of Y-shaped rock-inlaid trough section of diaphgram wall and trough-forming construction method thereof

A technology for underground diaphragm wall and grooved construction, which is applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve problems such as inability to adapt to the corners of grooves, reduce construction risks, improve stability, and ensure smooth construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

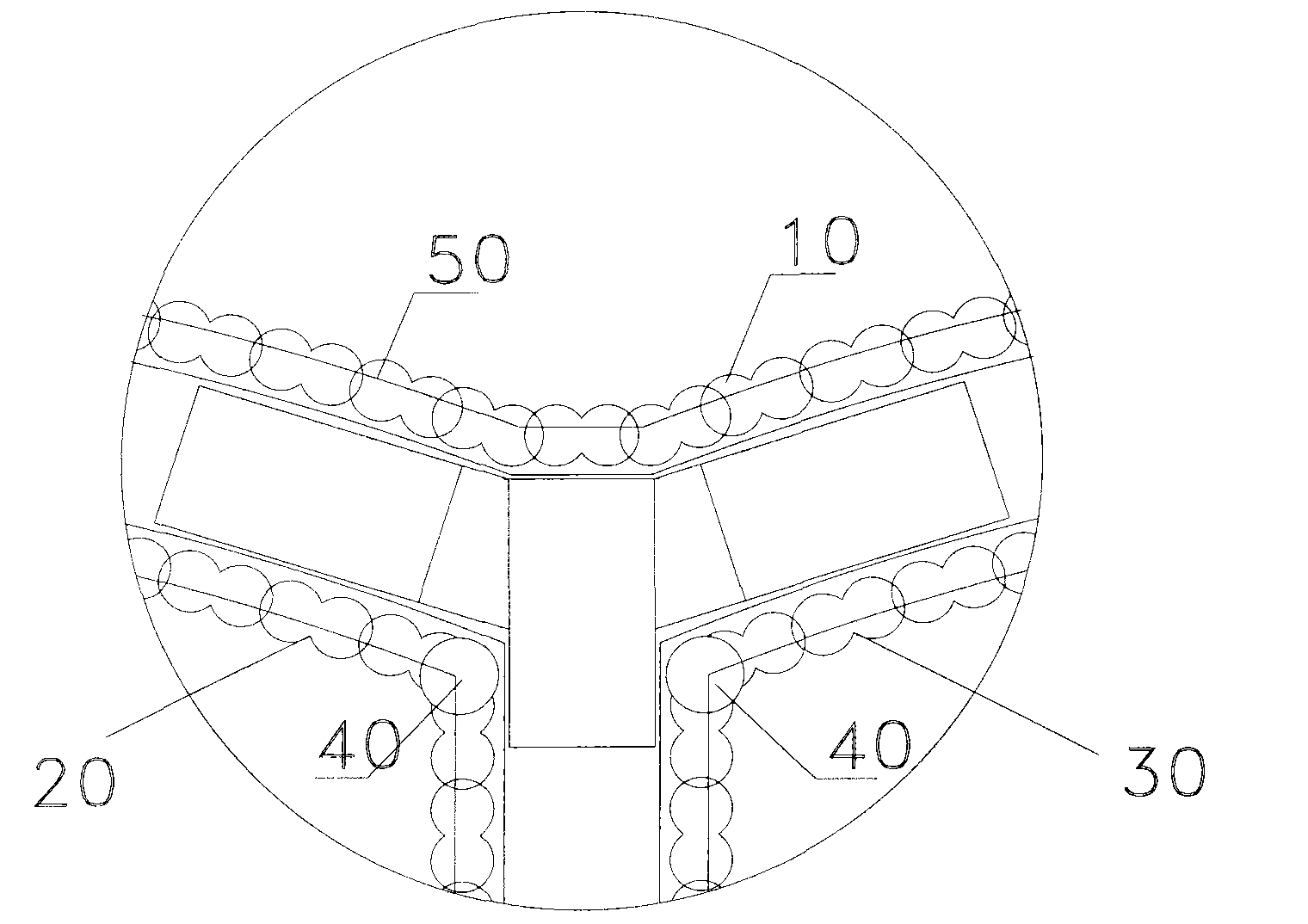

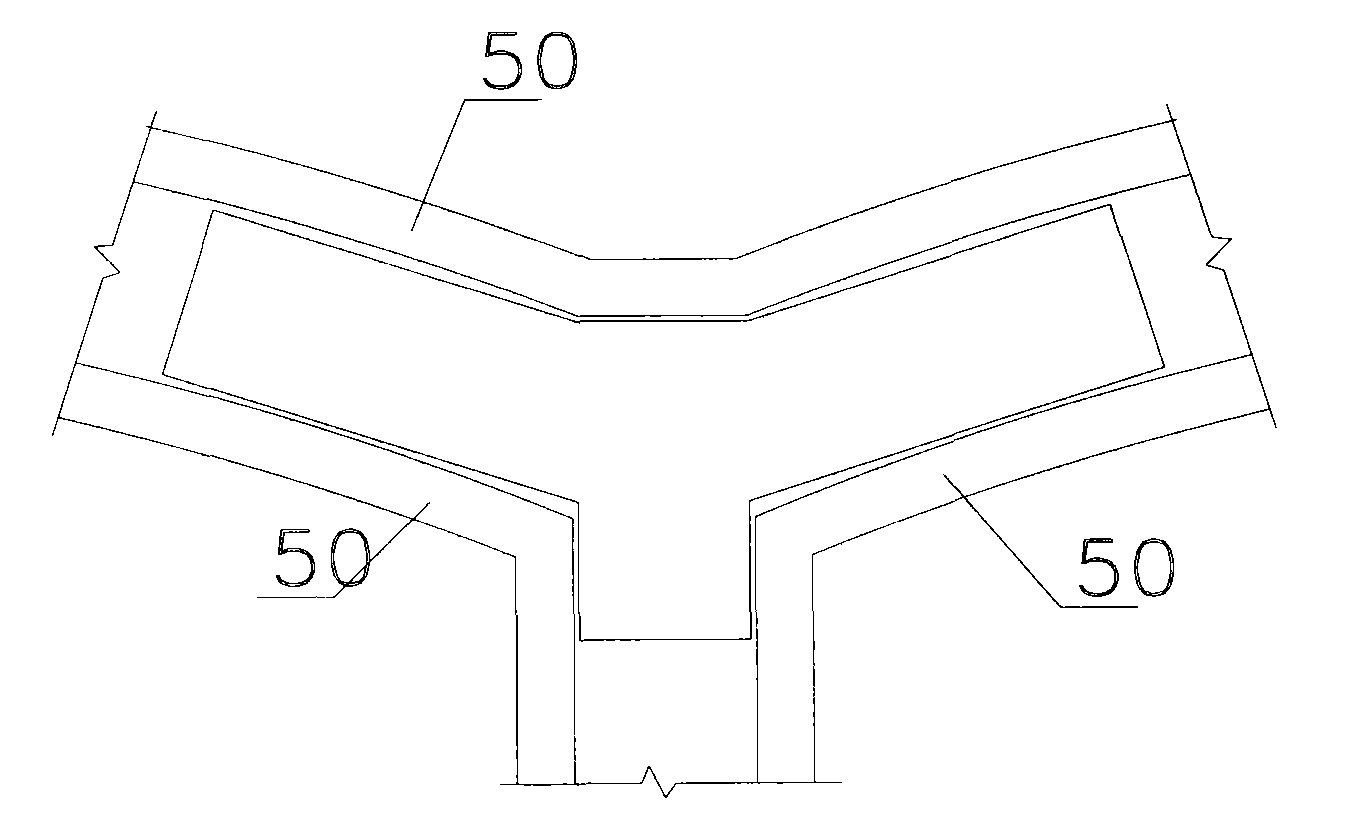

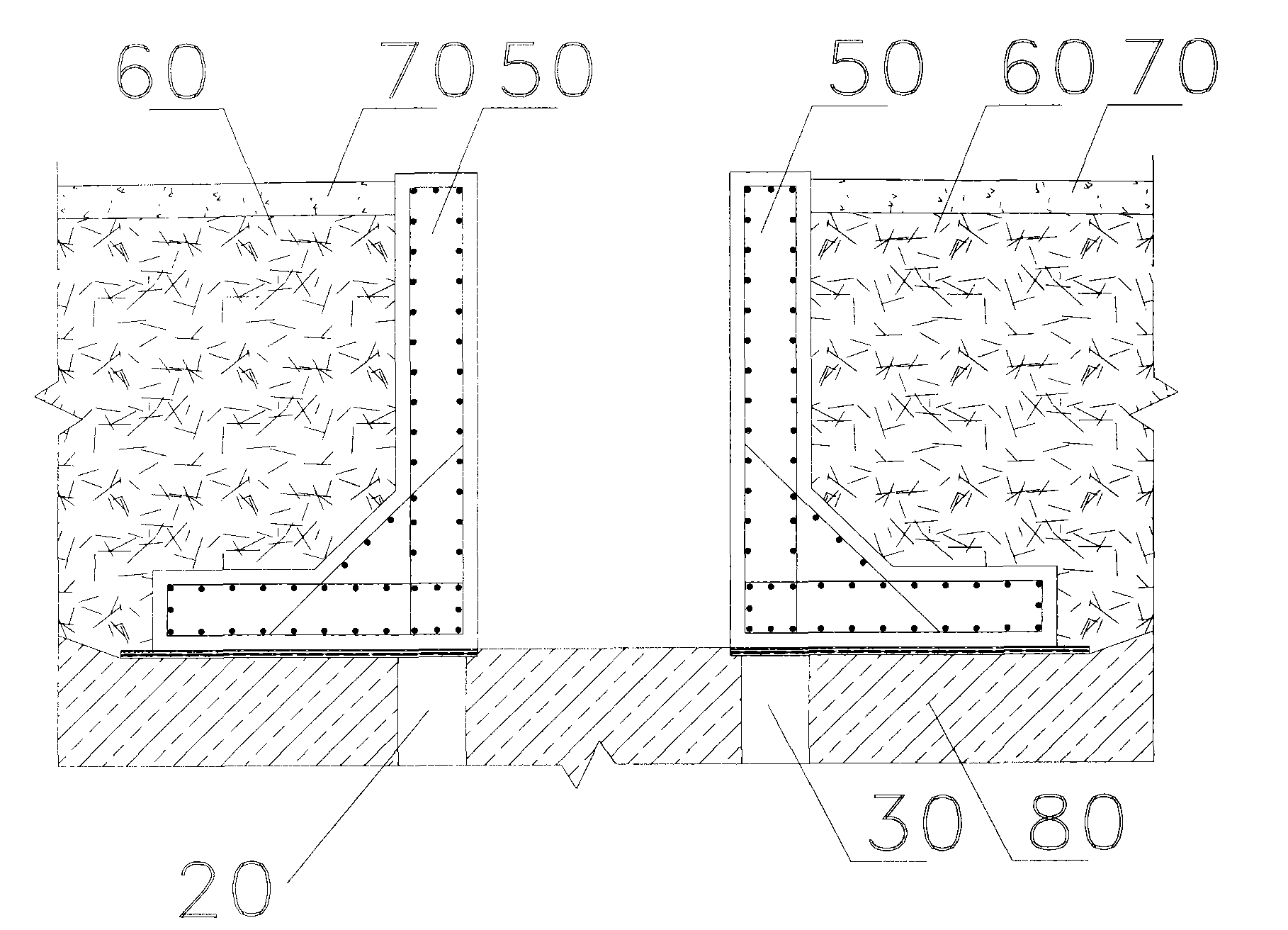

[0012] The Fourth Nanjing Yangtze River Bridge adopts a double-tower three-span suspension bridge, and the south anchorage foundation adopts a shaft-type underground diaphragm wall structure. It consists of a partition wall. The thickness of the underground diaphragm wall is 1.50m, the total depth is 40.00m~50.00m, and it is embedded in moderately weathered sandstone for about 3.00m. The construction groove section of the underground diaphragm wall includes two Y-shaped special-shaped groove sections, which are located at the junction of the partition wall and the outer wall.

[0013] Such as figure 1 As shown, three "V" shaped cement-soil deep-layer mixing pile walls 10, 20, 30, each cement-soil deep-layer mixing pile is in the shape of "8", are connected to each other to form a pile wall. Three "V"-shaped cement-soil deep-layer mixing pile walls constitute a "Y"-shaped groove section profile; wherein, the corners of cement-soil deep-layer mixing pile walls 20 and 30 (that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com