Adjustable gear shifting cable joint for automobile

An adjustable, automotive technology, applied in the directions of flexible shafts, linear motion shafts, shafts, etc., can solve the problem of inconsistent transmission strokes, and achieve the effect of simplifying operation and improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

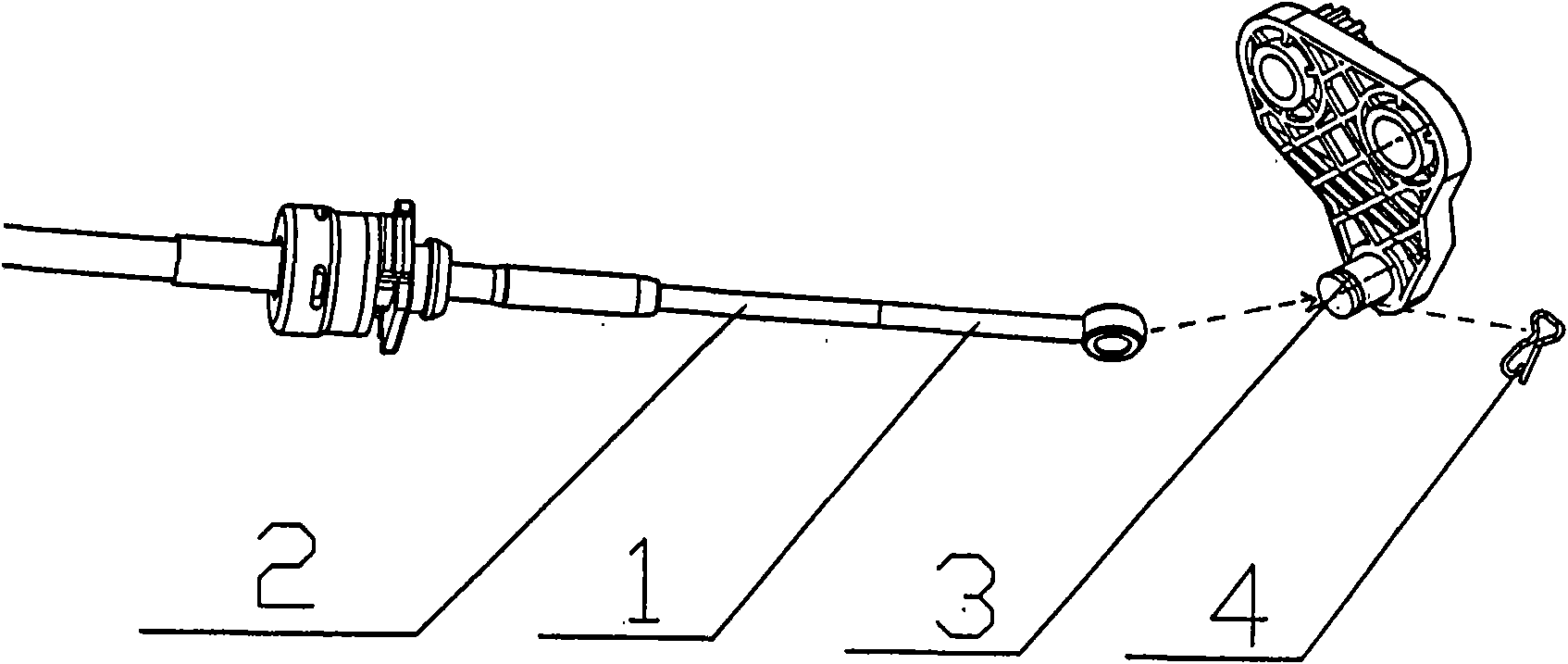

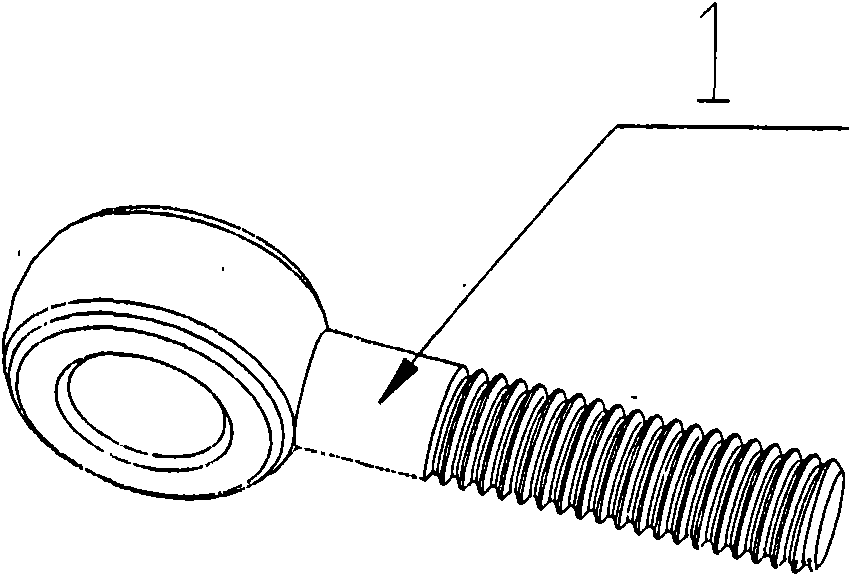

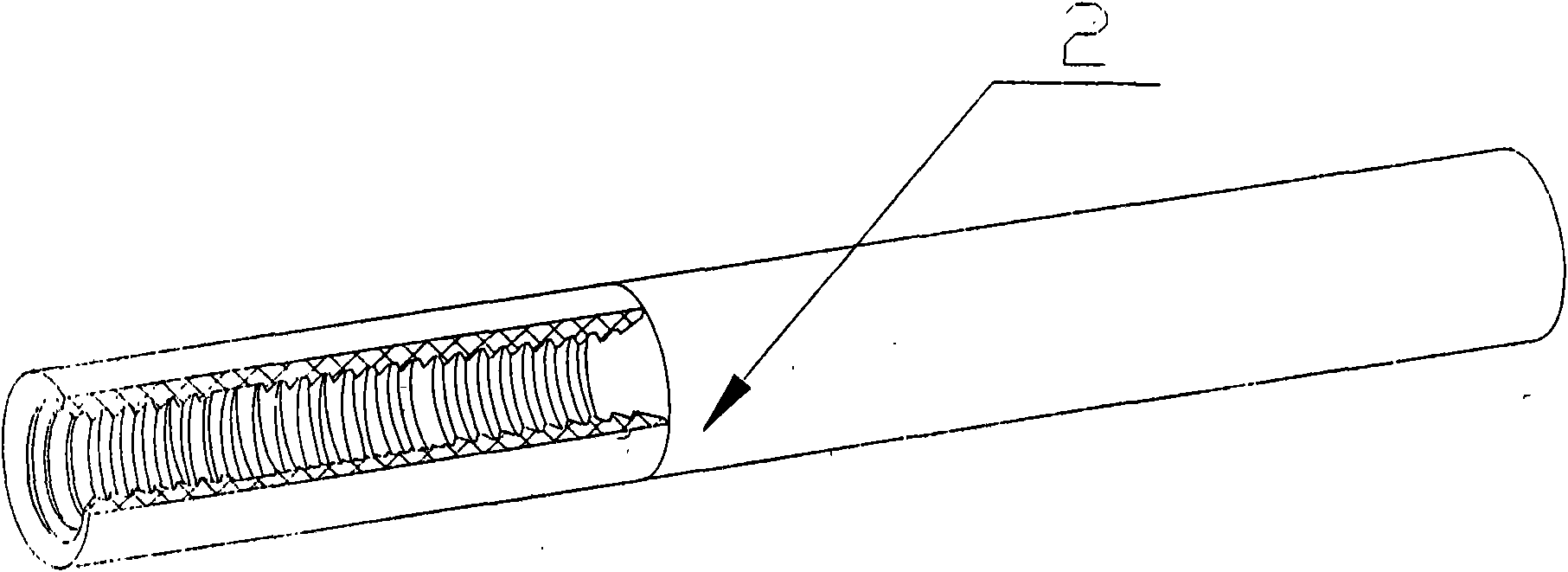

[0016] see figure 1 , figure 2 and image 3 , the gear shift cable joint is composed of a transposition cable clevis joint 1 and a transposition cable worm 2. One end of the transposition cable earring joint 1 is connected with the transposition pin 3 of the shift handle, and is fixed by an elastic clip 4, and the other end of the transposition cable earring joint 1 has an external thread. One end of transposition cable worm 2 has internal thread, is connected with the external thread of transposition cable earring joint 1 other end, and the other end of transposition cable worm 2 and transposition cable core wire are fixed by riveting.

[0017] During the assembly process of the shift cable, after the assembly of each installation position is completed, the shift cable connector 1 needs to be installed in the shift pin 3 of the shift handle, and then fixed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com