High-precision coaxial coupling mechanism

A coupling mechanism and high-precision technology, which is applied in the direction of rigid shaft couplings, couplings, mechanical equipment, etc., can solve the problems of large space occupation, inappropriateness, and difficult disassembly, so as to save space, improve service life, and apply wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in conjunction with accompanying drawing:

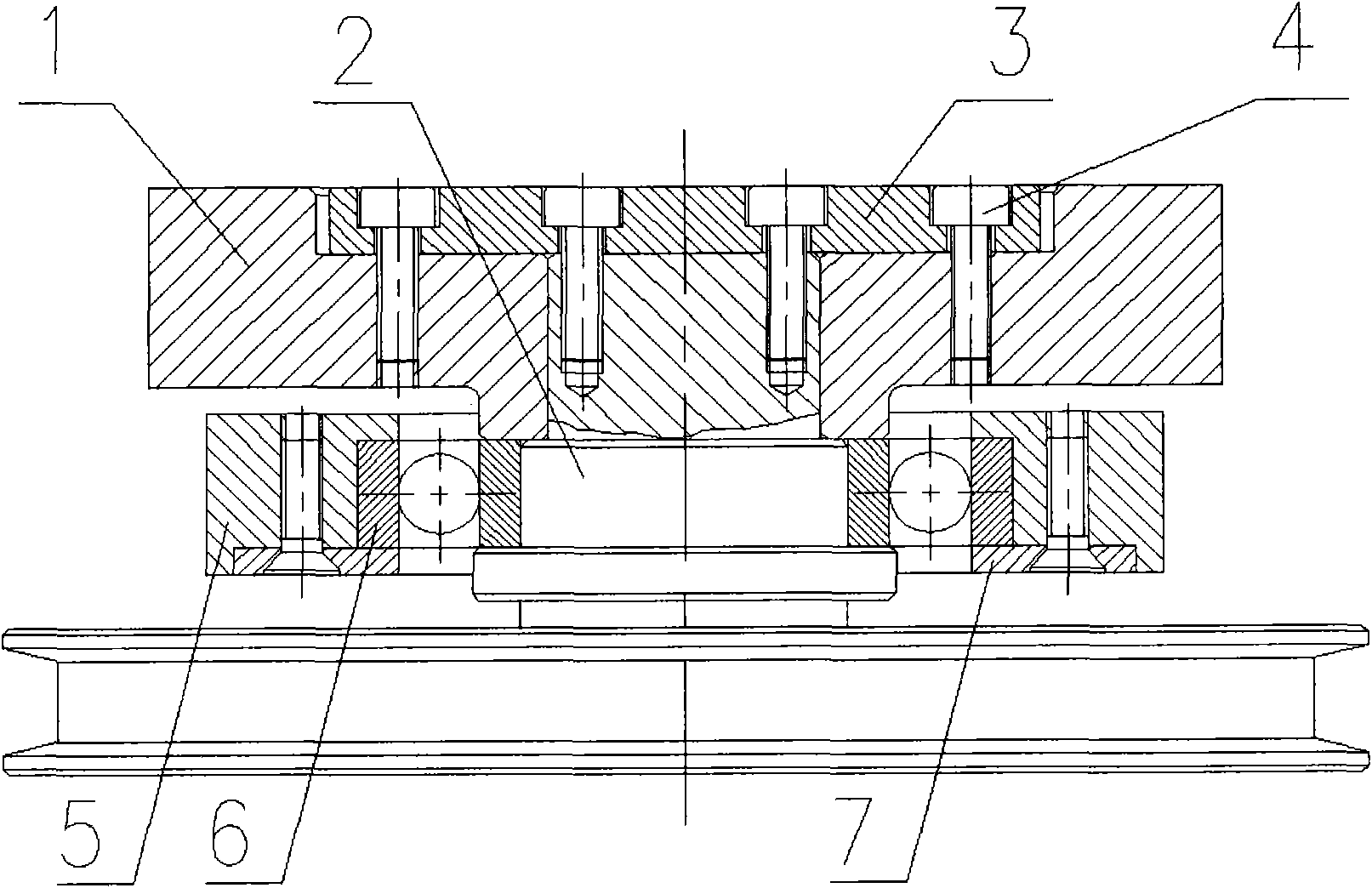

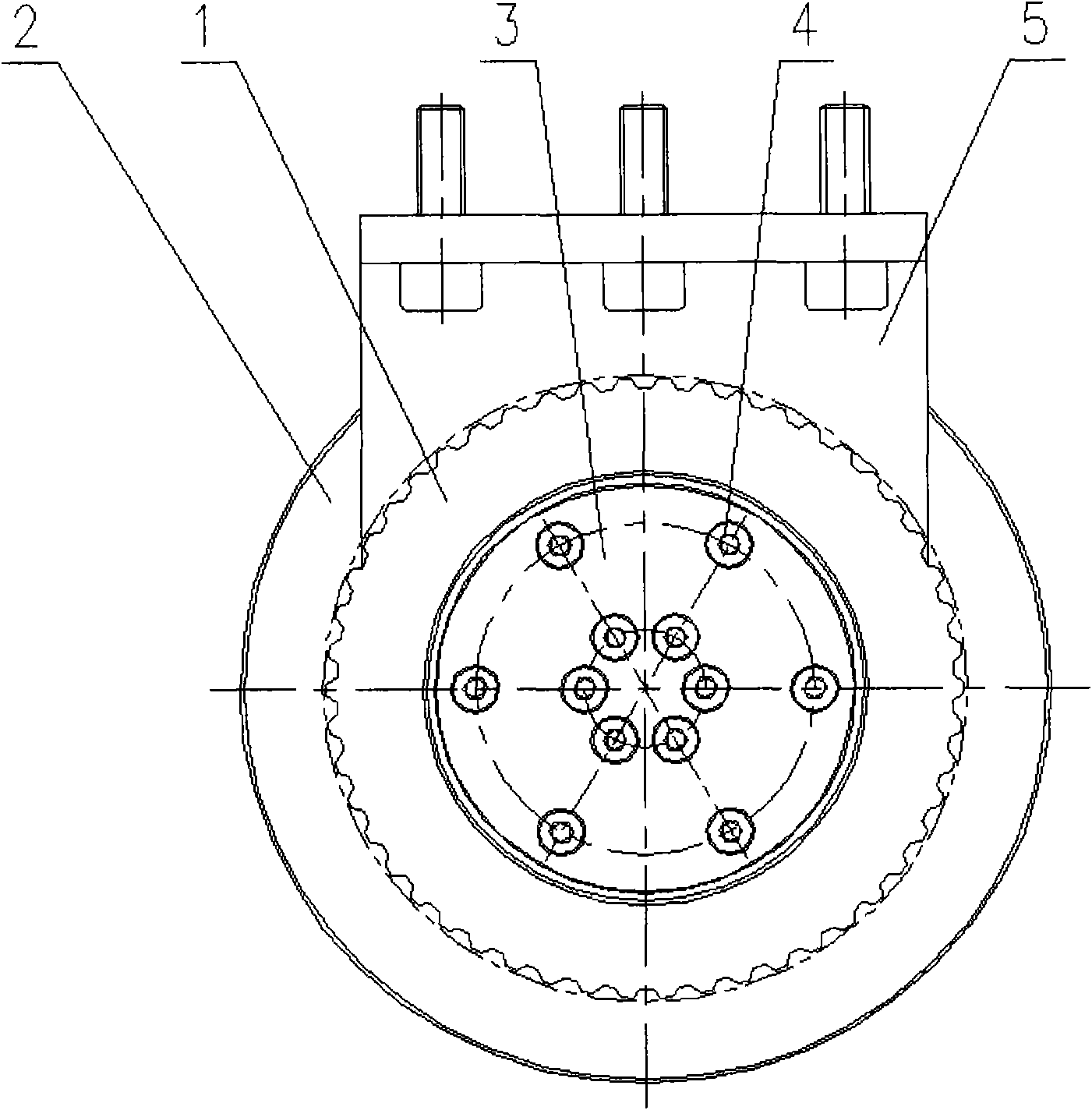

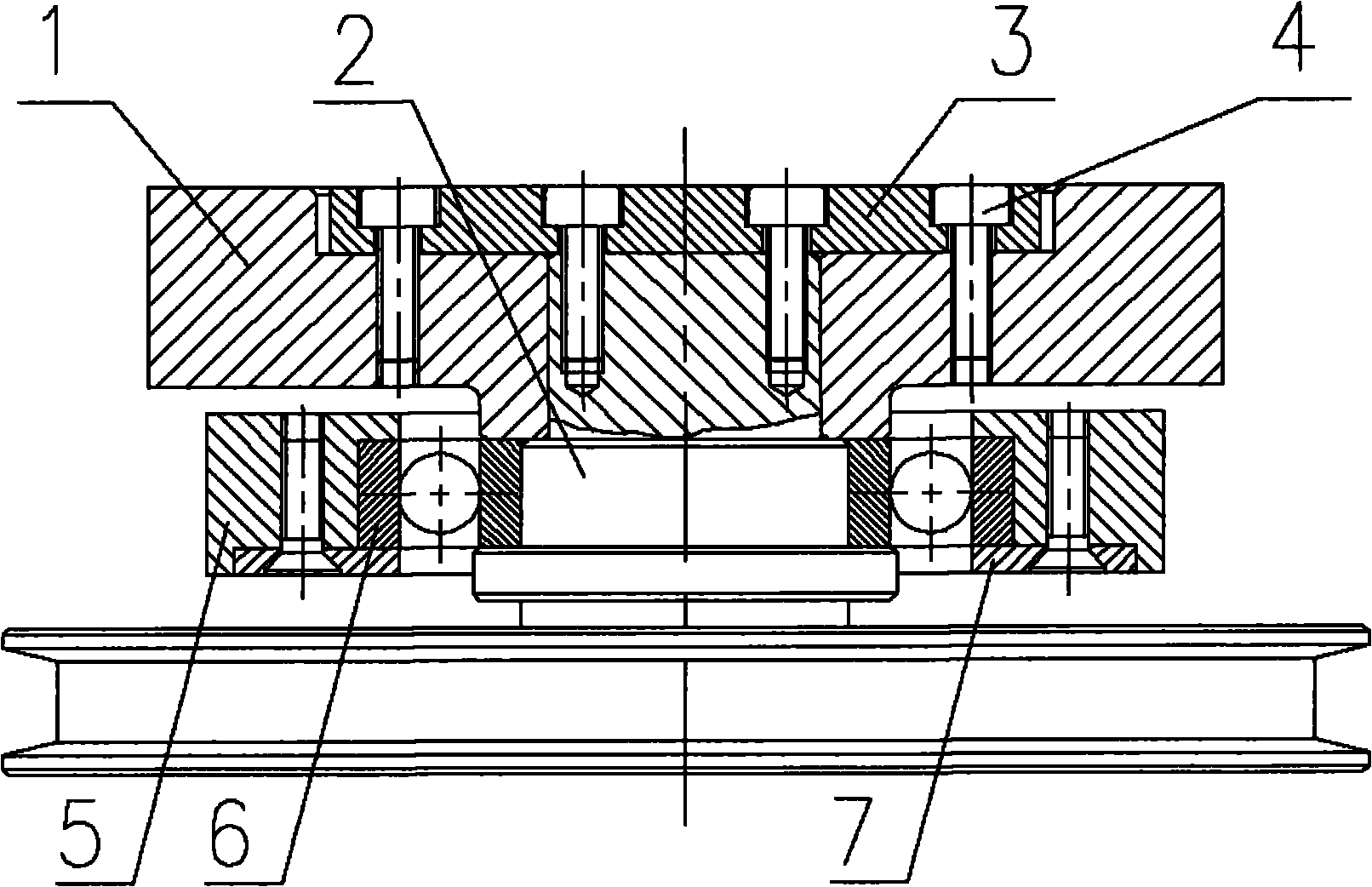

[0015] Referring to the accompanying drawings, a high-precision coaxial coupling mechanism includes a secondary transmission wheel 1, a main transmission wheel shaft 2, a coupling plate 3, a coupling screw 4, a mounting plate 5, a bearing 6, a bearing compression ring 7, and the like. When installing, first install the bearing 6 into the mounting plate 5 by the "hot packing method", press the bearing 6 with the bearing pressing ring 7, and tighten the fastening screws. Put the small end of the main transmission wheel shaft 2 into the 6 holes of the bearing for alignment, and put it on the hand press to press it in place. The hole of the secondary drive wheel 1 is installed on the corresponding position of the corresponding main drive wheel shaft 2. The main transmission wheel shaft 2 and the secondary transmission wheel 1 adopt clearance fit. By controlling the processing accur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com