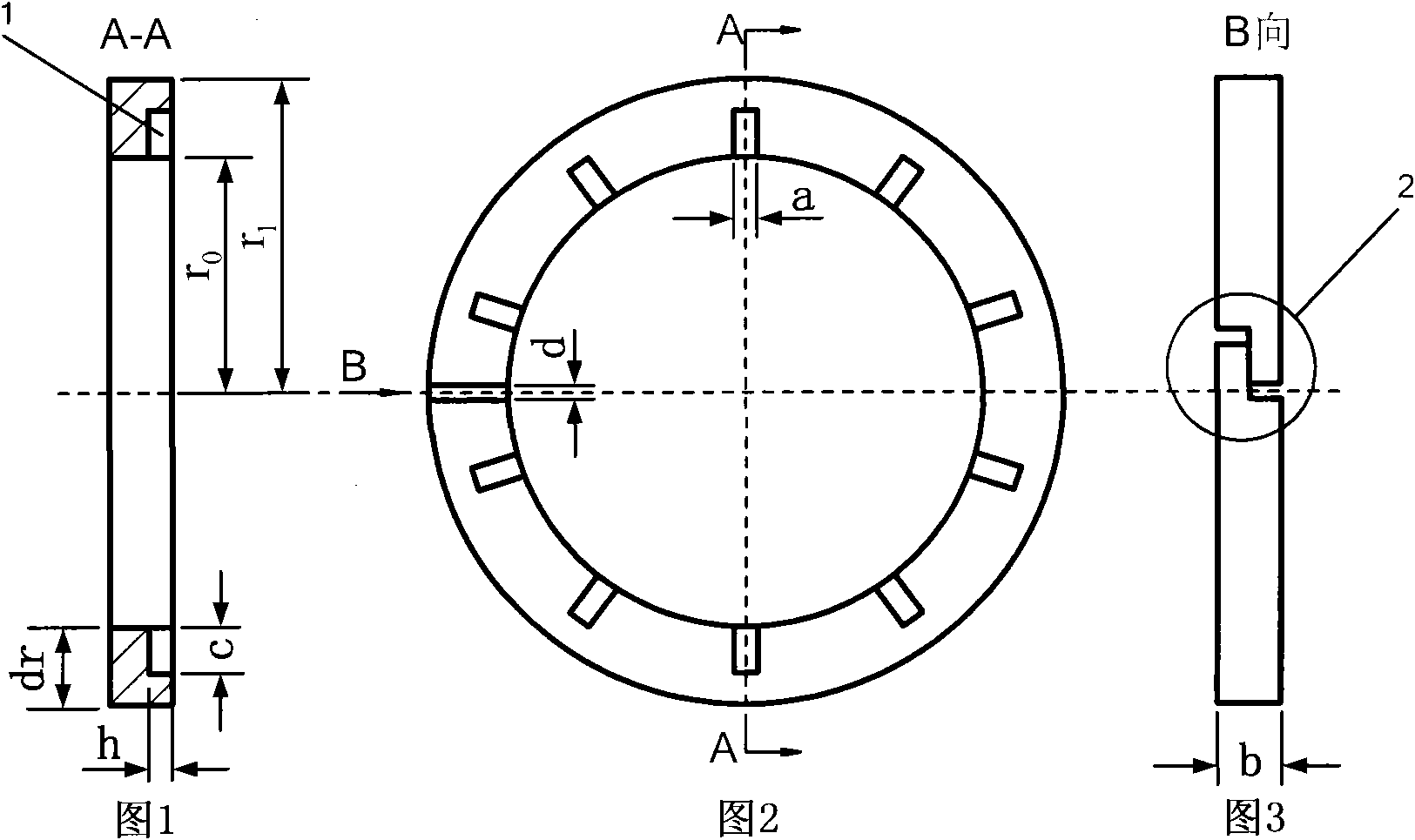

Sealing ring with isobathic rectangular groove on end surface

A rectangular groove and sealing ring technology, applied in the field of liquid rotary sealing parts, can solve the problems of rotary sealing ring failure, sealing end face wear, thermal cracking, etc., and achieve the effect of improving work performance and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

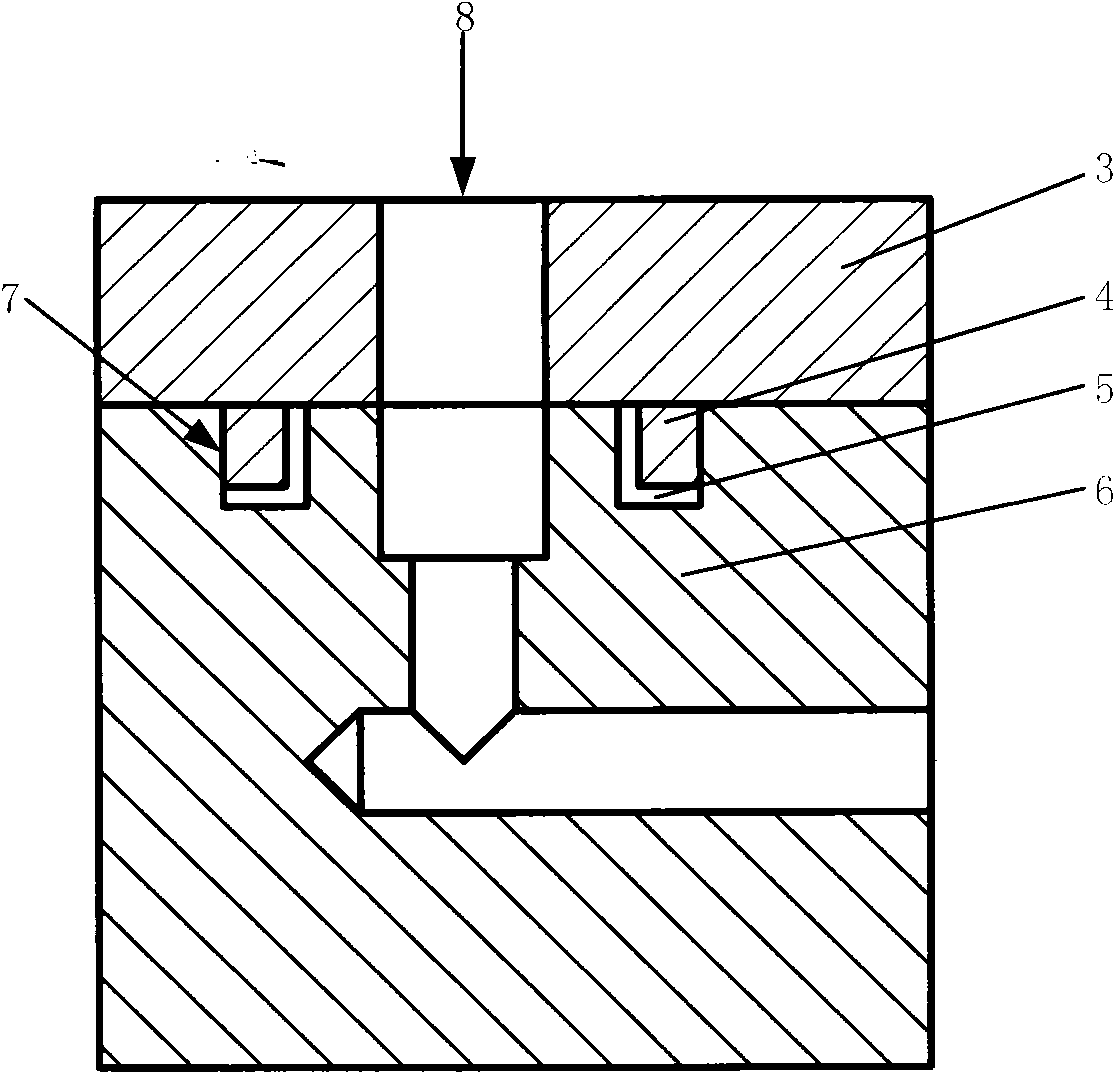

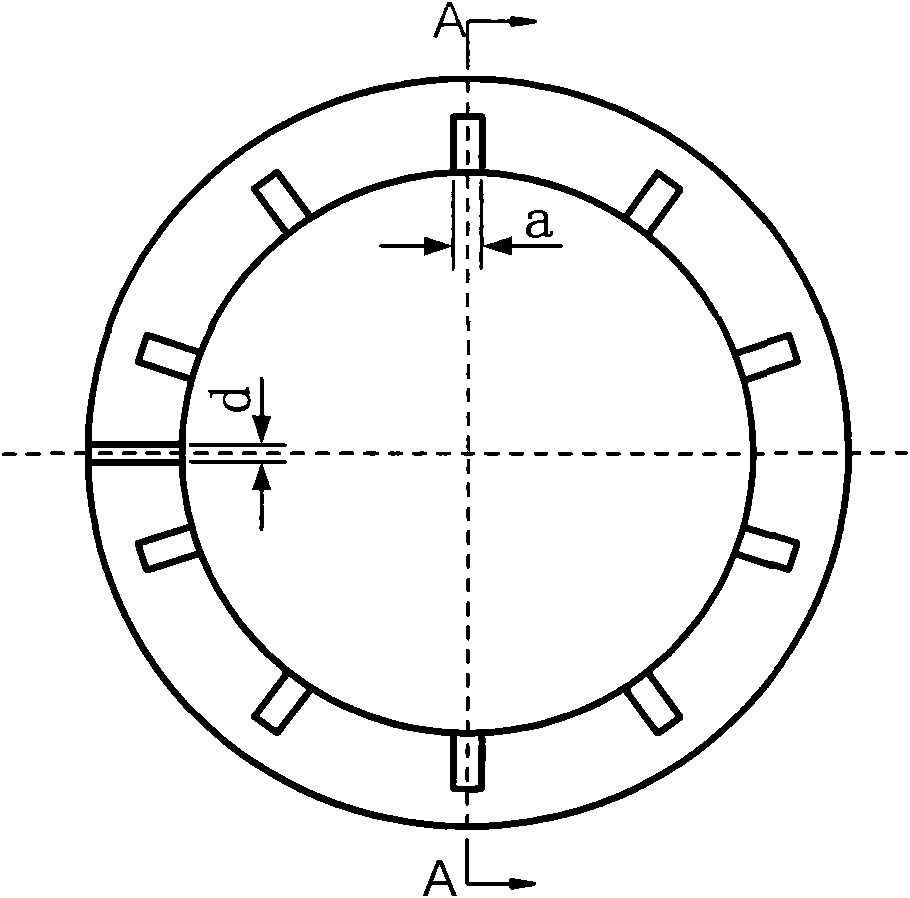

[0012] see Figure 4 , which shows the installation state of the rotary seal ring in the wet clutch. As shown in the figure, (8) in the figure is the oil inlet of the clutch. The oil inlet sleeve (3) is used to supply oil to the wet clutch, and the oil inlet sleeve is non-rotating; the oil distribution sleeve (6) is used to supply oil to the wet clutch. The piston cylinder of the clutch distributes oil, and the oil distribution sleeve rotates together with the clutch shaft; the outer circular surface of the oil distribution sleeve (6) has a sealing ring installation groove (5), and the rotating sealing ring is just installed in this groove. Before assembly, the oil inlet sleeve (3) and the oil distribution sleeve (6) need to be separated; then the rotating seal ring (4) should be stretched and inserted into the seal ring installation grooves on the outer circle of the oil distribution sleeve (6) (5), note that the side with the rectangular groove (1) on the seal ring (4) must...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com