Petroleum gas steel bottle control valve

A technology of LPG and control valves, applied in the direction of control valves, valve details, valve devices, etc., can solve the problems of easy stealing, easy leakage, low inflation efficiency, etc., to avoid illegal inflation, ensure inflation quality, The effect of preventing air stealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

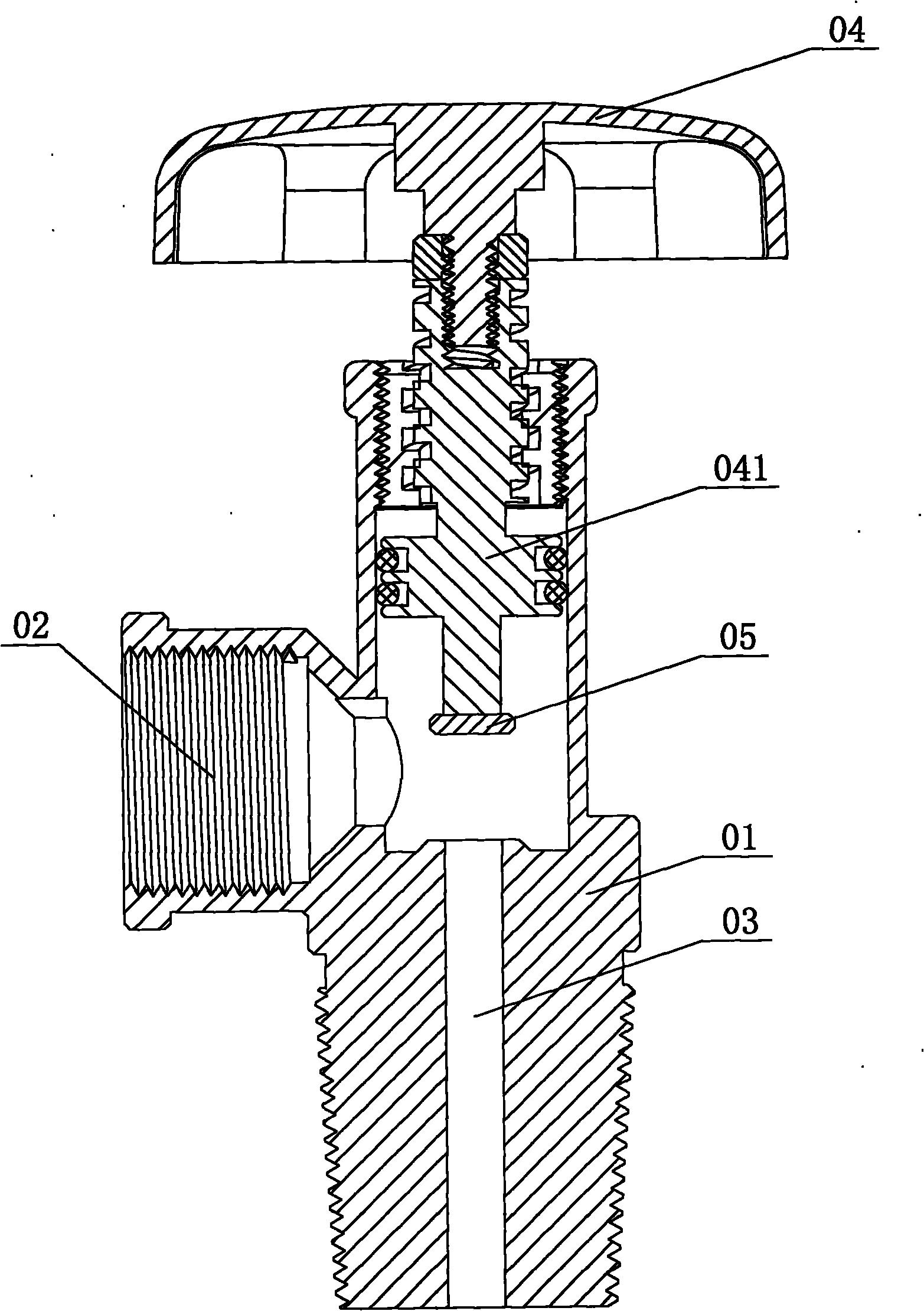

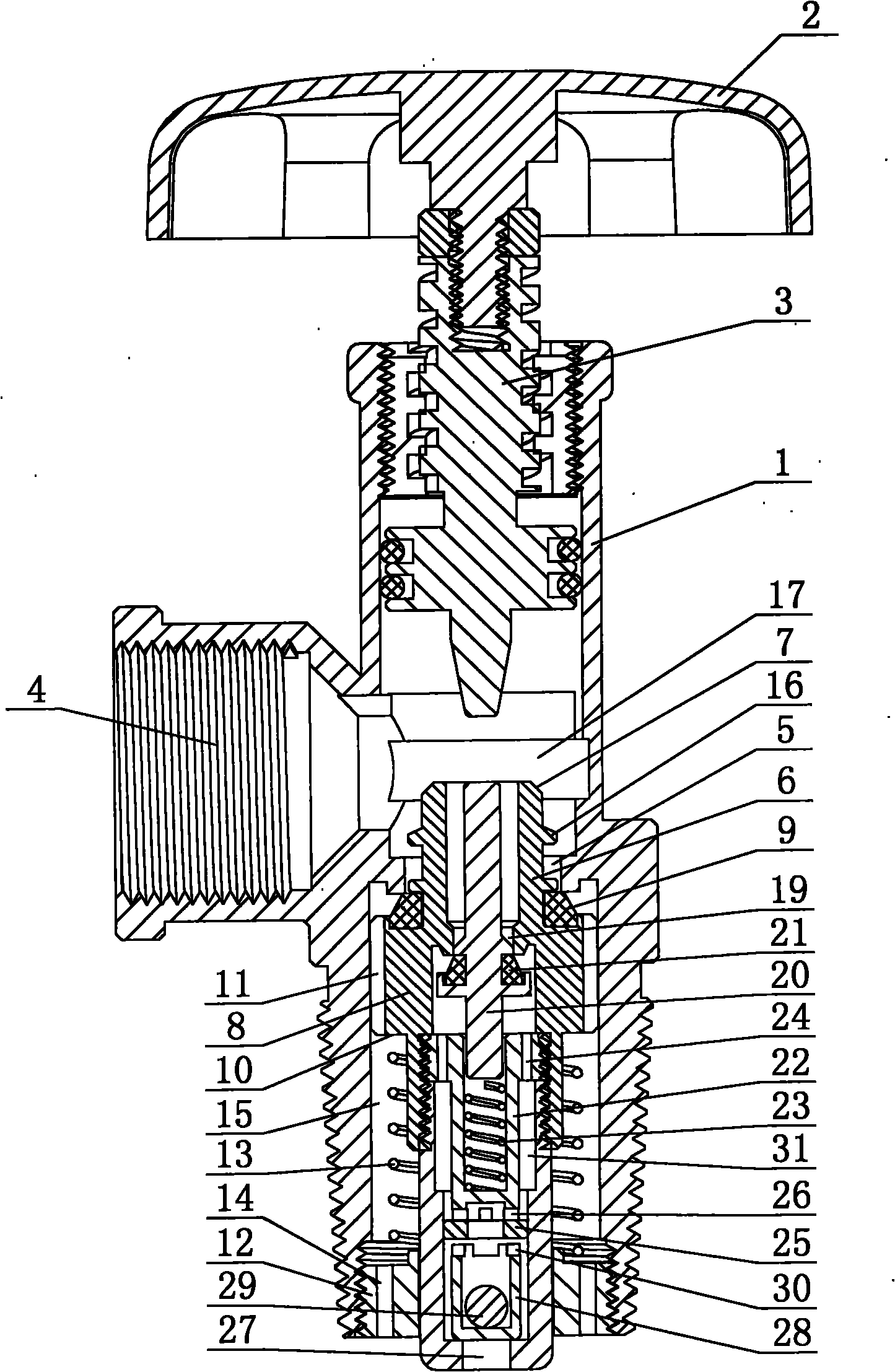

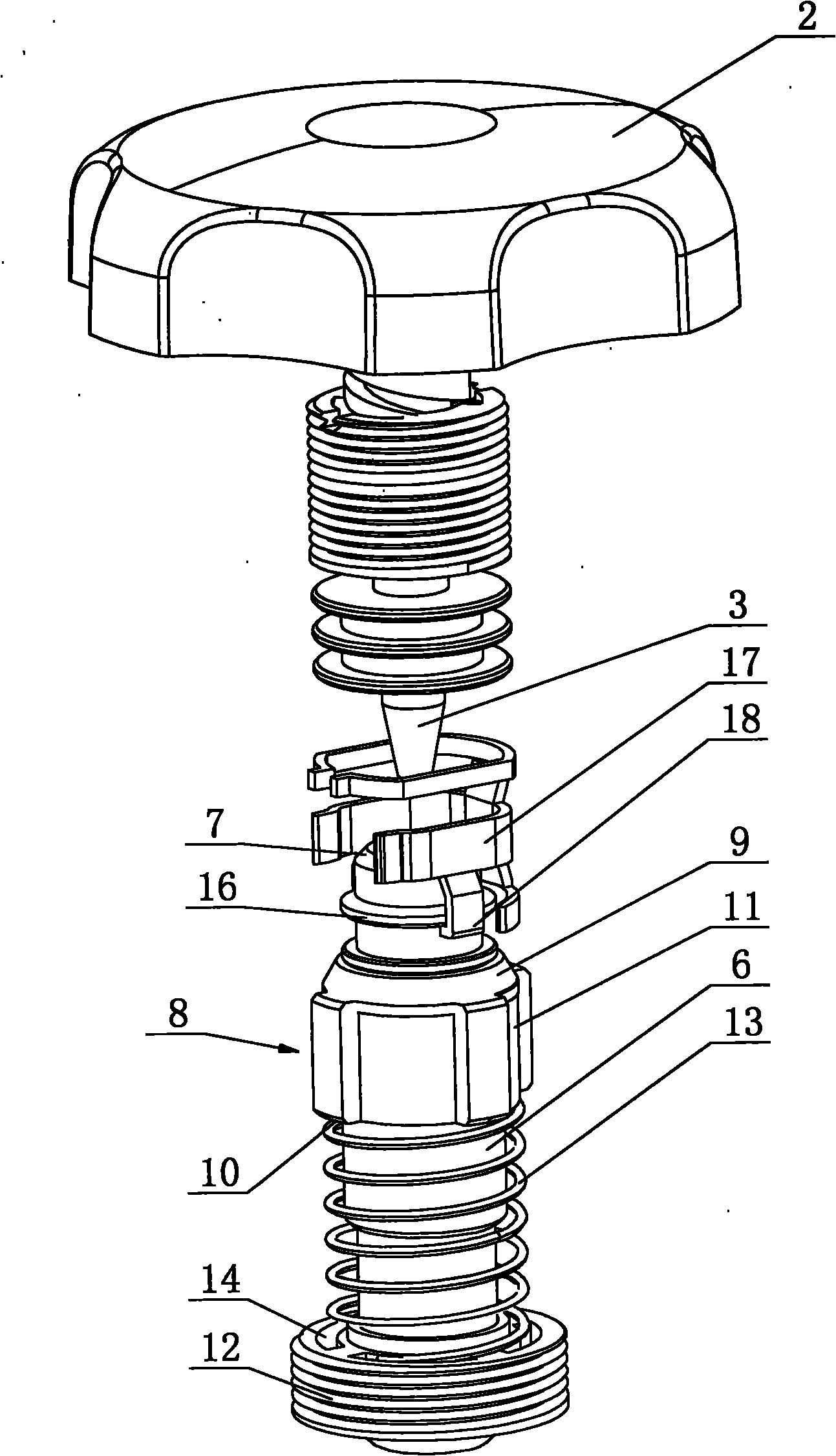

[0026] Now elaborate the present invention in conjunction with accompanying drawing:

[0027] The petroleum gas cylinder control valve includes a hollow valve body 1, a handwheel 2, a handwheel rotating shaft 3 and a gas delivery port 4. The handwheel rotating shaft 3 is a lower pressure rod, and the lower outer peripheral surface of the hollow valve body 1 is processed with threads. Thread, the hollow valve body 1 is installed on the top of the LPG cylinder, and the first closing port 5 and the lifting sleeve 6 are arranged in the hollow valve body 1. The structure of the lifting sleeve 6 is as follows: Figure 10 As shown, the lifting sleeve 6 is divided into two parts, an upper cylinder 61 and a lower cylinder 62. The upper cylinder 61 and the lower cylinder 62 are connected together by threads, and the top of the lifting sleeve 6 extends upwards to the gas delivery port 4. And the top edge is processed with a guide chamfer 7, and a convex ring 8 is formed on the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com