Tubular part assembling clip for vehicle

A technology of component assembly and pipes, applied in the field of pipe clamps, can solve the problems of inconvenient maintenance and disassembly of pipes, disengagement of pipes, failure of pipes to be fixed together, etc., and achieve the effect of convenient fixing and dismounting of pipes and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments, but the scope of protection claimed by the present invention is not limited to the scope expressed by the embodiments. Any transformation equivalent to the technical solution according to the present invention belongs to the protection scope of the present invention. .

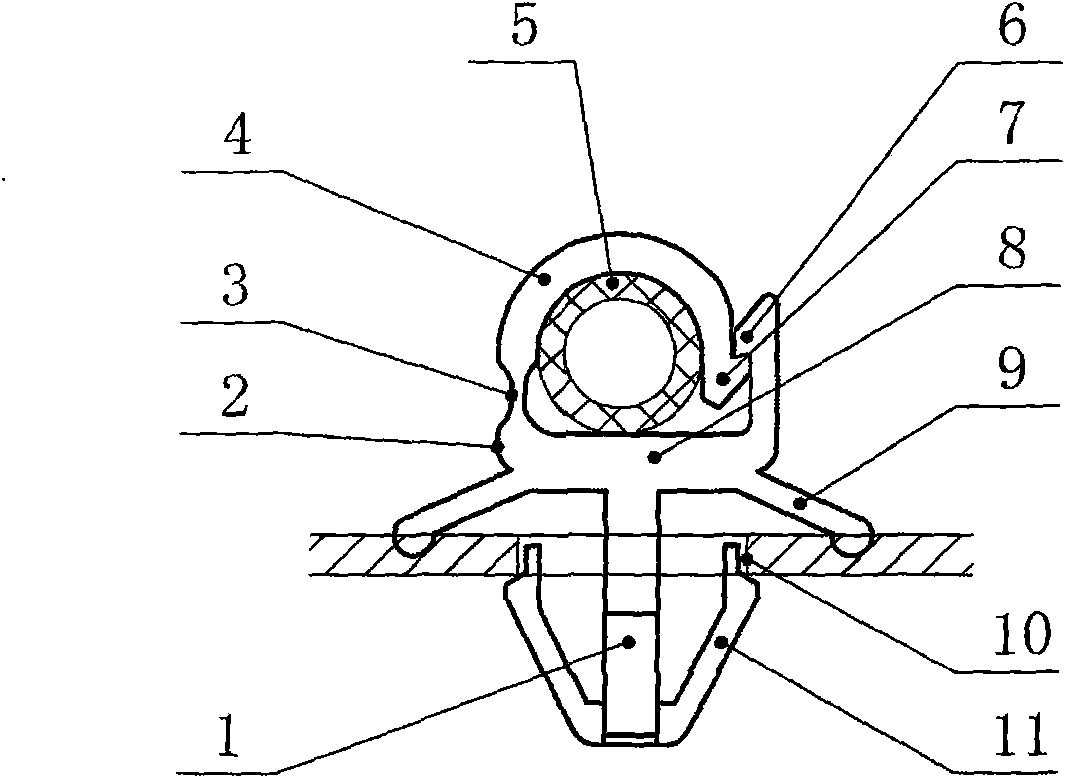

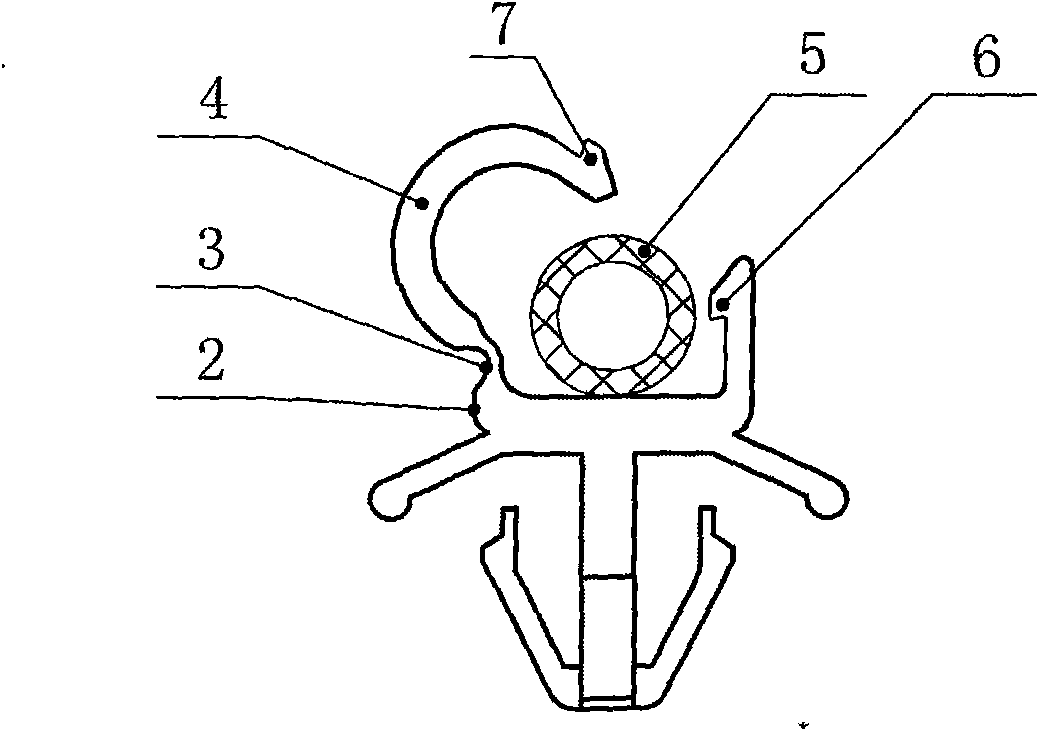

[0020] See figure 1 with figure 2 , The clip has a card body 2 for holding the tube-like component 5 and a card foot 1 that is matched with the card hole 19 on the vehicle body.

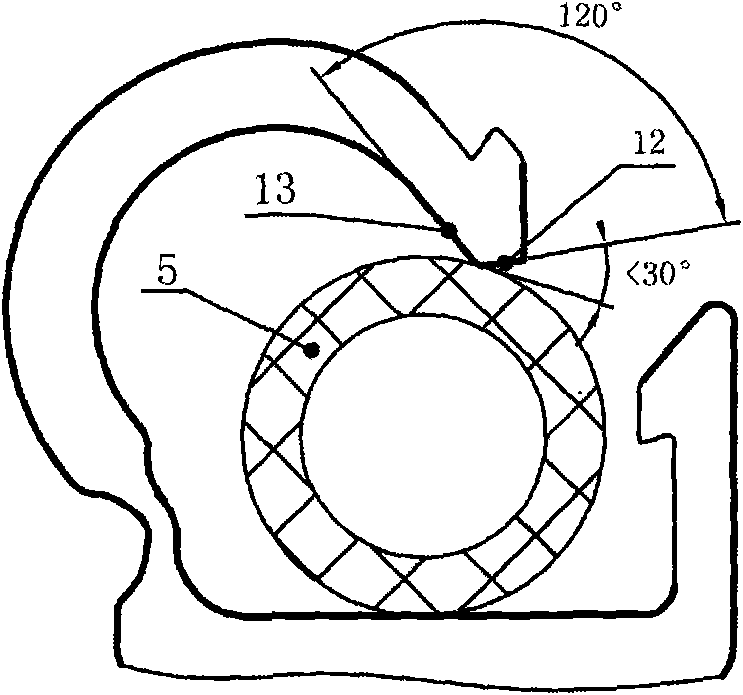

[0021] The card body 2 is a locking card body, which has a buckle base 8 and a movable buckle strip 4, one end of the movable buckle strip 4 is connected with the buckle base, and the connecting part is formed by thinning the material during molding In the shaft structure 3, the other end of the movable buckle 4 forms an inner lock buckle 7, which is buckled with the outer lock buckle 6 at the corresponding end of the buckle bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com