Heater arrangement structure for improving temperature distribution uniformity of melt of aluminium isothermal smelting furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

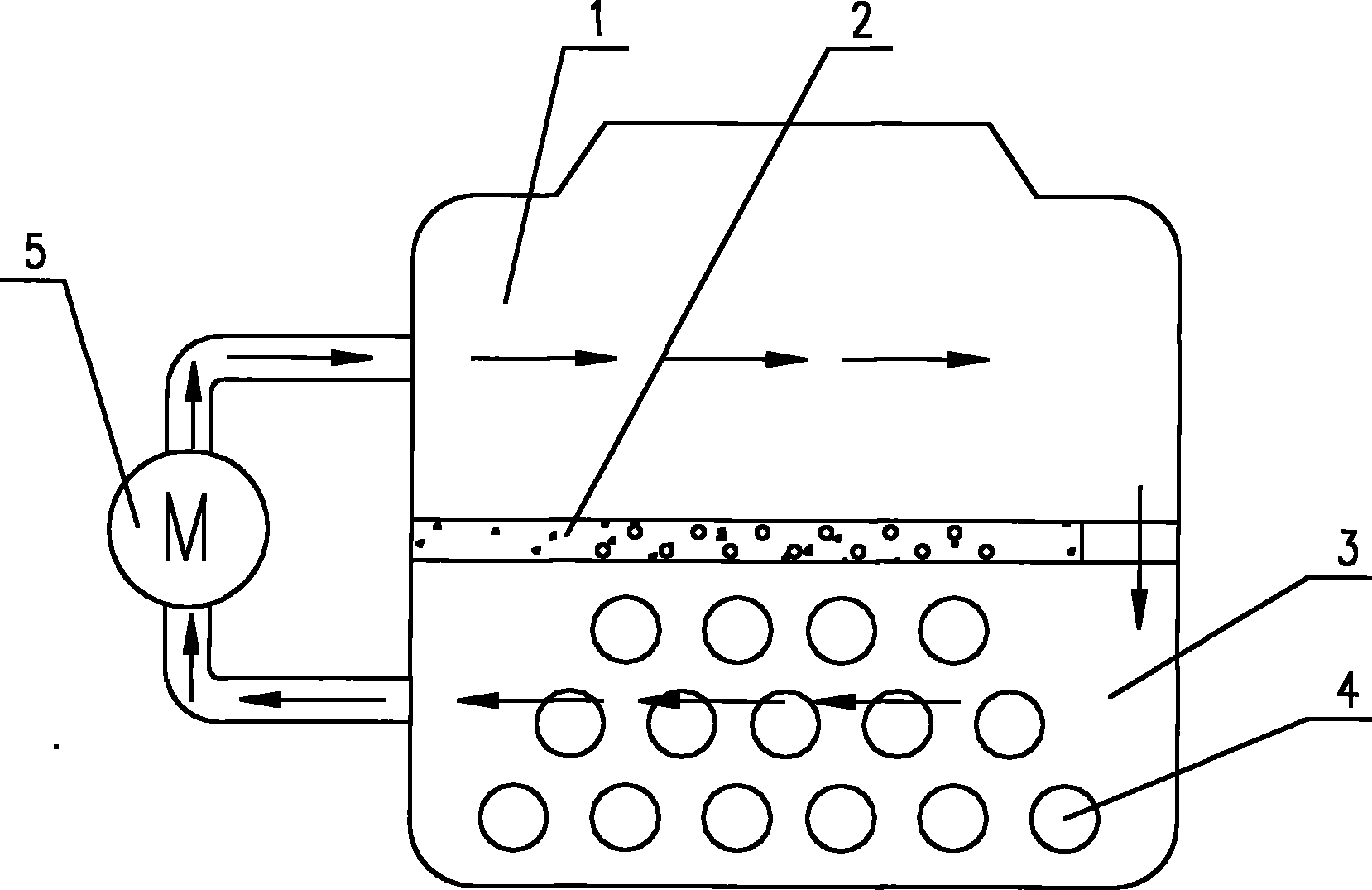

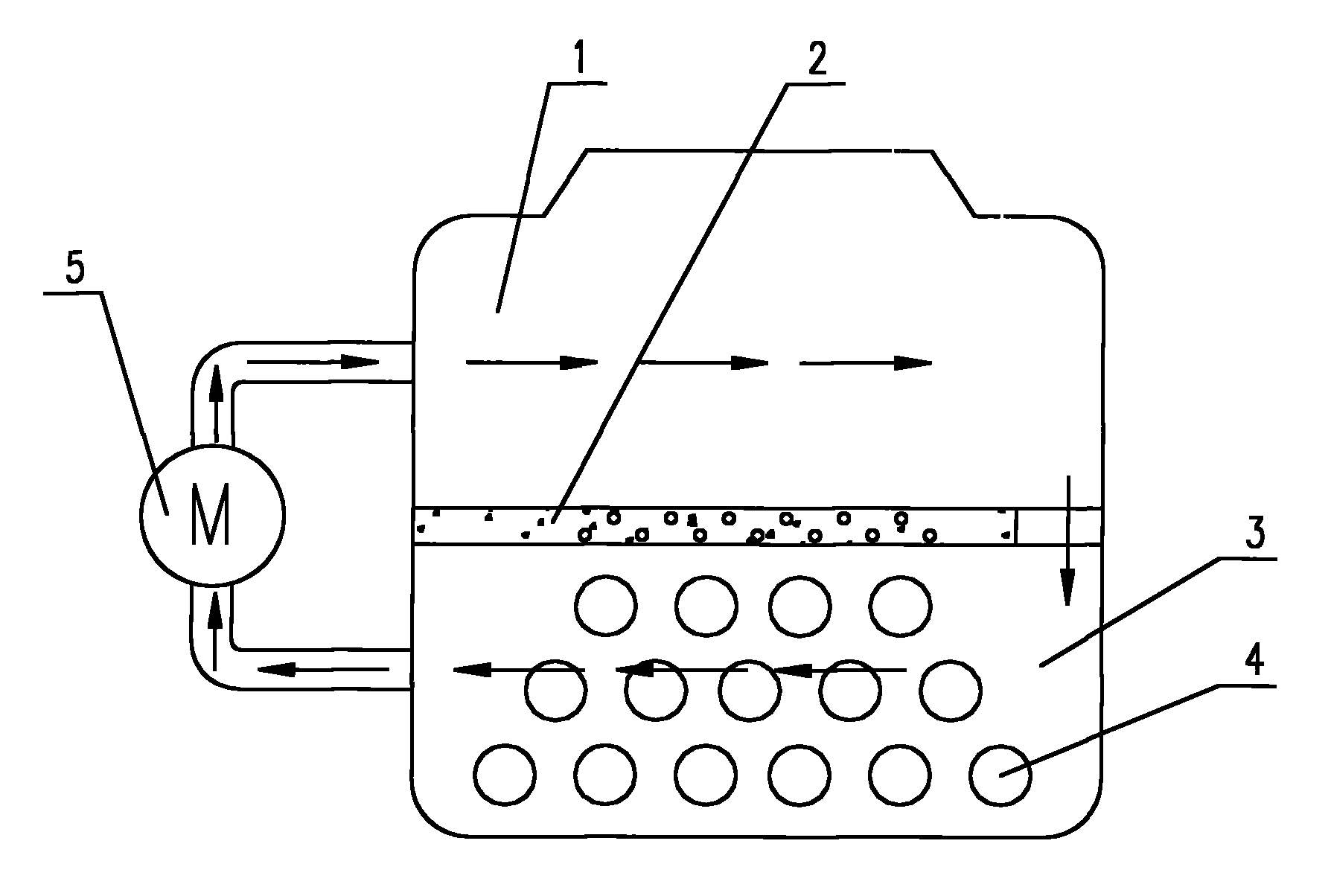

[0019] like figure 1 As shown, the heater arrangement structure for improving the temperature distribution uniformity of the melt in the aluminum isothermal melting furnace is provided with a partition wall 2 in the middle of the hearth of the isothermal melting furnace, and the partition wall 2 divides the hearth into a melting zone 1 and a heating zone 3. Area 3 is non-uniformly arranged with heaters 4. The heaters 4 are submerged gas heaters or submerged electric heaters. The heaters 4 are arranged in parallel between the partition wall 2 and the opposite furnace wall, and the number increases row by row. Increase by 1 respectively, the distance between adjacent heaters in each row is equal, the distance between rows is equal, and the heaters form a staggered arrangement. An aluminum liquid circulation pump 5 is arranged outside the isothermal melting furnace, the inlet of the aluminum liquid circulation pump 5 is connected to the heating zone 3, and the outlet of the alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com