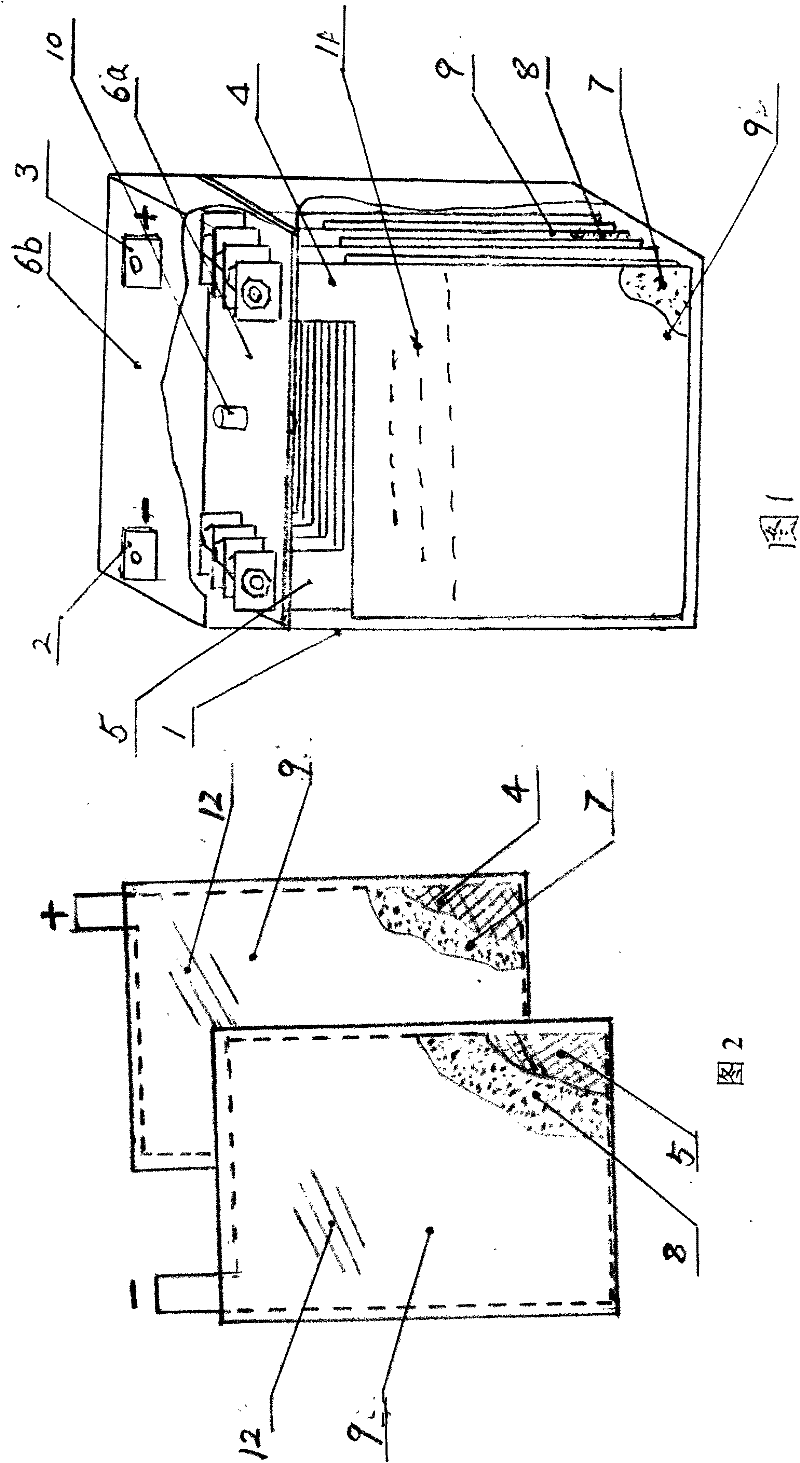

High-performance zinc-nickel storage battery

A zinc-nickel battery and battery technology, applied in nickel batteries, alkaline batteries, battery pack components, etc., can solve the problems of low operating voltage, high cost, short life, etc., and achieve growth inhibition, prevention of internal short circuit, and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

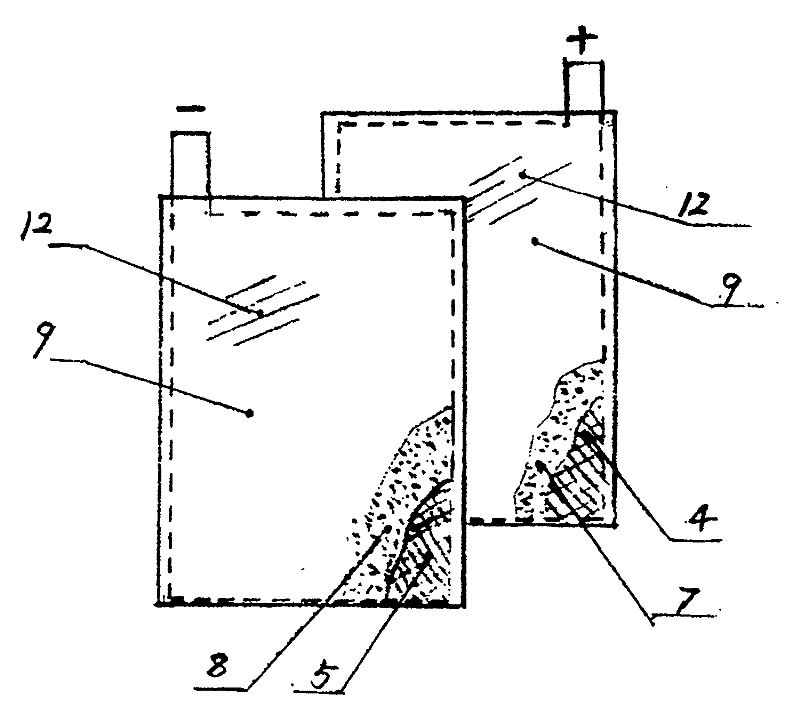

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 The making and using method of diaphragm and paint of this embodiment:

[0036] Use cotton paper as a diaphragm

[0037] (1) Put metal aluminum in NaOH solution to react to generate Na[Al(OH) 4 ],which is:

[0038] NaOH+Al+H 2 O→Na[Al(OH) 4 ]+H 2 ↑

[0039] (2) In the above Na[Al(OH) 4 ] in the solution, add Mg(OH) 2 react, generate

[0040] Mg[Al(OH) 4 ] 2 sediment, namely:

[0041] Mg(OH) 2 +Na[Al(OH)]→Mg[Al(OH) 4 ] 2 ↓+NaOH;

[0042] (3) Wash the precipitate to remove Na[Al(OH) 4 ], Na[Al(OH) 4 ] content ≤ 0.2%;

[0043] (4) Drying at 100°C; crushing and sieving, Mg[Al(OH) with a particle size of 800-1000 mesh 4 ] 2 .

[0044] The method of applying the paint on the diaphragm is:

[0045] a. In Mg[Al(OH) 4 ] 2 In the solution, add 4-5% starch by weight, then add 200-220ml of water, stir evenly, heat the solution to boiling, and then cool it down;

[0046]b. The above Mg[Al(OH) 4 ] 2 Apply evenly on the diaphragm 9 for multiple c...

Embodiment 2

[0049] Embodiment 2 The preparation method and steps of this embodiment are:

[0050] Nylon cloth is used as the diaphragm.

[0051] (1) Put metal aluminum in KOH solution to react to generate Ca[Al(OH) 4 ] 2 ,which is:

[0052] KOH+Al+H 2 O→K[Al(OH) 4 ]+H 2 ↑

[0053] (2) In the above K[Al(OH) 4 ] to the solution, add Ca(OH) 2 react to generate Ca[Al(OH) 4 ] 2 sediment, namely:

[0054] Ca(OH) 2 +K[Al(OH) 4 ]→Ca[Al(OH) 4 ] 2 ↓+KOH.

[0055] (3) Wash the precipitate to remove K[Al(OH) 4 ], its content ≤ 0.2%;

[0056] (4) Dry at 120°C; pulverize and sieve with a particle size of 800-1200 mesh to obtain pure Ca[Al(OH) 4 ] 2 ;

[0057] The method of coating the coating agent on the diaphragm in this embodiment is similar to that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com