Water band

A technology for hoses and joints, which is applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of reducing the pressure resistance of hoses, low pressure resistance, and high scrap rate, and achieve simplified production processes and low energy consumption. Effect of reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

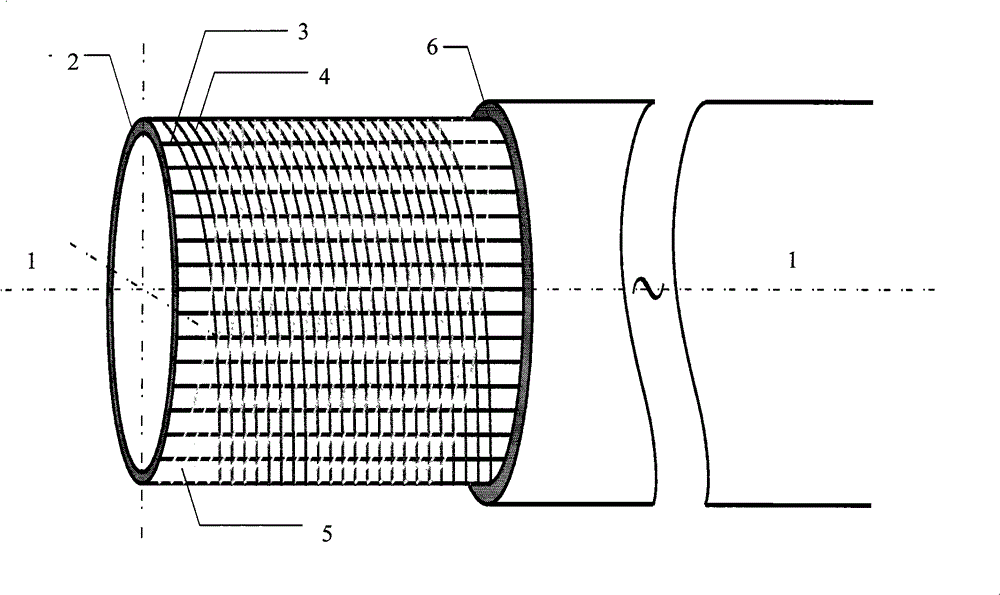

[0026] like figure 1 As shown, 1 is the center line of the hose of the present invention, 2 is the PVC inner rubber layer, 3 is the first straight fiber layer, 4 is the second winding fiber layer, 5 is the third winding fiber layer, and 6 is the PVC outer rubber Floor.

[0027] The water belt of the present invention is a circular or oblate water delivery hose, the pipe wall is a PVC glue layer, and the first straight fiber layer 3 is wrapped in the middle of the PVC glue layer, the second winding fiber layer 4 and the third winding layer are wrapped in the middle of the PVC glue layer. Fiber layer 5.

[0028] To manufacture the hose of the present invention, it is necessary to distribute a plurality of polyester straight lines on the outside of the PVC inner rubber layer 2 of the hose at an angle parallel to the center line 1 of the hose to form a first straight fiber layer 3; The center line 1 of the belt is the baseline, and a plurality of polyester threads are wound on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com