Method for treating filter cakes of leaf filter

The technology of filter cake and filter cake of leaf filter is applied in the improvement field of alumina production process, which can solve the effect of red mud sedimentation and separation effect in a washing sedimentation tank, poor sedimentation performance of red mud, and loss of attached liquid in the last red mud washing. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

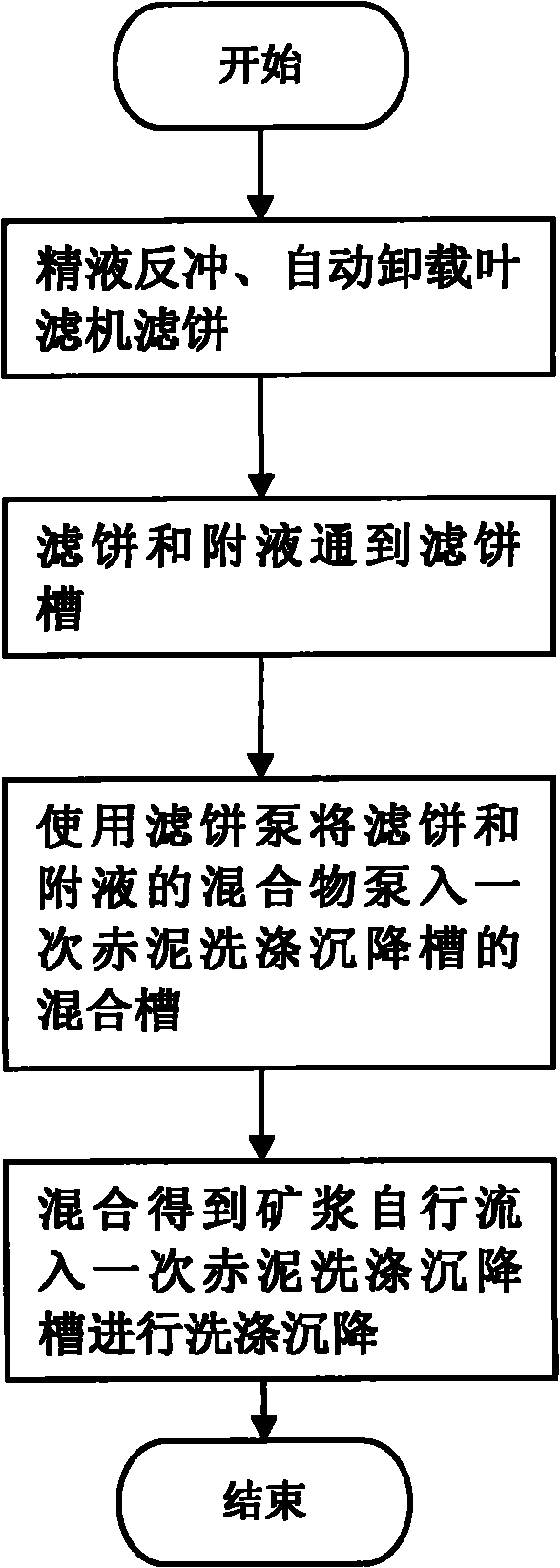

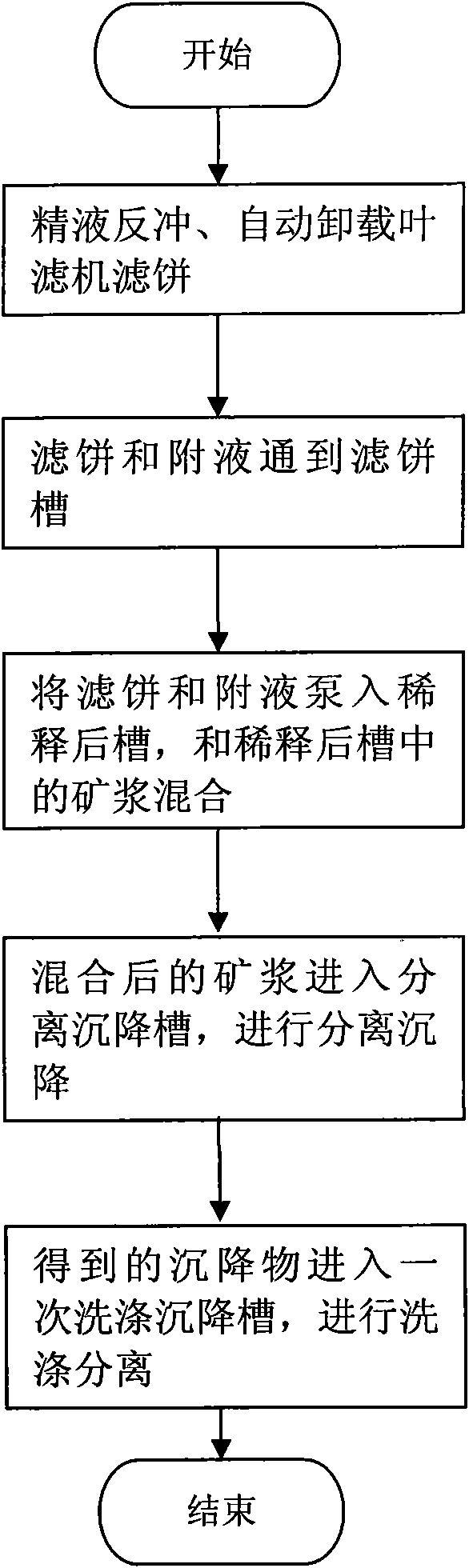

[0013] The method includes the following steps:

[0014] 1) Use semen to recoil to remove the filter cake;

[0015] 2) passing the filter cake and attached liquid into the filter cake tank;

[0016] 3) Use a filter cake pump to pump the filter cake and attached liquid from the filter cake tank into the diluted tank, and mix with the pulp in the diluted tank;

[0017] 4) then the mixed pulp obtained in step 3) enters the separation and settling tank for separation and settlement;

[0018] 5) The sediment obtained in step 4) enters a washing and settling tank for washing and separation.

[0019] The process flow of this method is not to directly pass the filter cake and its attached liquid to the primary washing and settling tank, but first to the post-dilution tank. Liquid loss, reducing the amount of alkali taken away with the last red mud discharge; reducing the overflow Na of a red mud washing settling tank 2 The concentration of O can reduce the amount of washing liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com