Method for darkly dyeing PLA (polylactic acid) filament yarn fabrics

A filament fabric, dark color technology, applied in the field of textile printing and dyeing, can solve the problems that affect the normal use and application range of PLA products, PLA filament fabrics cannot be dyed in dark colors, PLA fibers are acid-resistant and alkali-resistant, etc., to improve dyeing performance And deep color, good dyeing effect, and the effect of improving the problem of dark dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

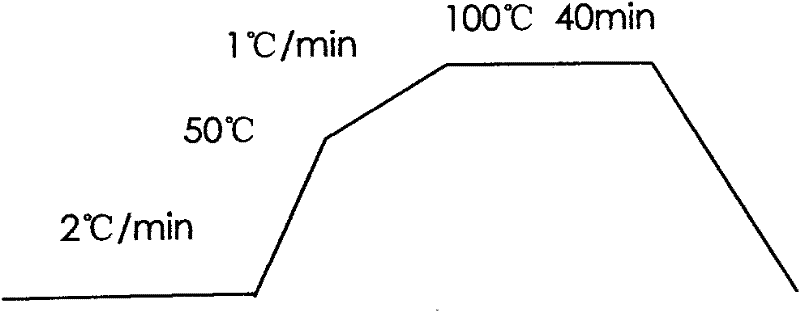

[0025] The PLA filament fabric was treated with low-temperature plasma in a low-temperature plasma equipment. The treatment conditions were: power 60W, time 60S, and the treatment atmosphere was air. The treated PLA filament fabric was dyed with Dianix (Blue) XF. Dyeing conditions: dye 1% (o.w.f), diffusing agent NNO 1g / L, bath ratio 1:30, adjust the pH value to 4-5 with acetic acid, the dyeing process is as follows figure 1 Shown: press figure 1 After dyeing with the shown heating curve, washing with water, reducing washing, washing with water and drying.

[0026] The PLA filament fabric dyed in Example 1 and the PLA filament fabric treated by conventional dyeing process were tested for dye uptake and k / s value. The test results showed that the dye uptake of PLA filament fabric without plasma treatment was 46.7%, k / s value is 3.12, the dye uptake rate of PLA filament fabric treated by plasma is 58.9%, k / s is 4.23, dye uptake rate and k / s growth rate are 26.12% and 35.58%, respect...

Embodiment 2

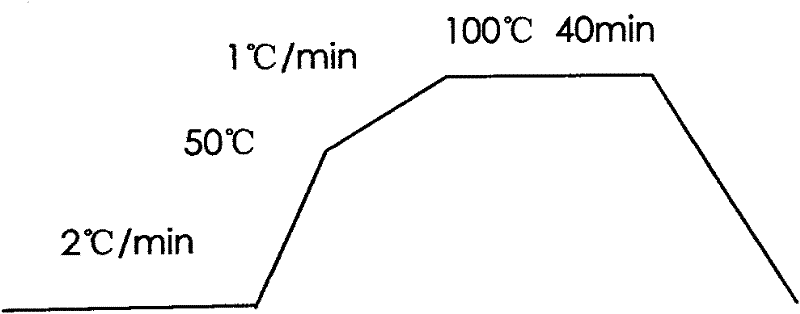

[0028] The PLA filament fabric was treated with low-temperature plasma in a low-temperature plasma equipment. The treatment conditions were: power 100W, time 100S, and the treatment atmosphere was air. The treated PLA filament fabric was dyed with Dianix (Blue) XF. Dyeing conditions: dye 1% (o.w.f), diffusing agent NNO 1g / L, bath ratio 1:30, adjust the pH value to 4-5 with acetic acid, the dyeing process is as follows figure 2 Shown: press figure 2 After dyeing with the shown heating curve, washing with water, reducing washing, washing with water and drying.

[0029] The PLA filament fabric dyed in Example 2 and the PLA filament fabric treated by the conventional dyeing process were tested for dye uptake and k / s value. The test results showed that the dye uptake of PLA filament fabric treated by plasma 64.1%, k / s was 5.23, dye uptake rate and k / s growth rate were 37.26% and 67.63%, respectively.

Embodiment 3

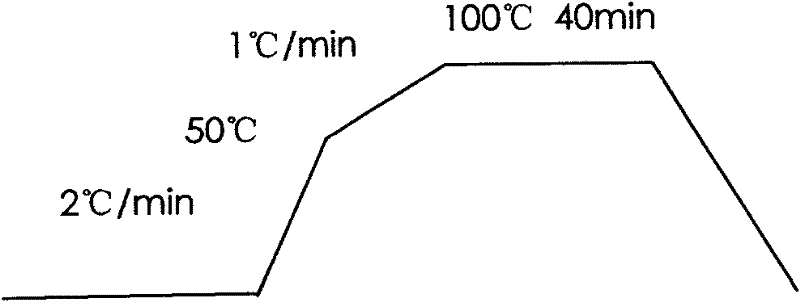

[0031] Low-temperature plasma treatment was performed on the PLA filament fabric in a low-temperature plasma equipment. The treatment conditions were: power 100W, time 100S, and treatment atmosphere as air. The treated PLA filament fabric was immersed in 30% acrylic acid solution for 60 minutes. The PLA filament fabric was then dyed with Dianix (Blue) XF. Dyeing conditions: dye 1% (o.w.f), diffusing agent NNO 1g / L, bath ratio 1:30, adjust the pH value to 4-5 with acetic acid, the dyeing process is as follows image 3 Shown: press image 3 After dyeing with the shown heating curve, washing with water, reducing washing, washing with water and drying.

[0032] The PLA filament fabric dyed in Example 3 and the PLA filament fabric treated by conventional dyeing process were tested for dye uptake and k / s value. The test results showed that the dye uptake of PLA filament fabric treated by plasma was 72.1%, k / s was 6.32, dye uptake rate and k / s growth rate were 54.39% and 103.56%, respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com