Plastic lamp holder

A lamp cap and plastic part technology, applied in the field of plastic parts lamp caps for lighting, can solve the problems of flux outflow, lamp cap corrosion and rust, affecting product quality, etc., and achieve the effect of reducing pollution and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

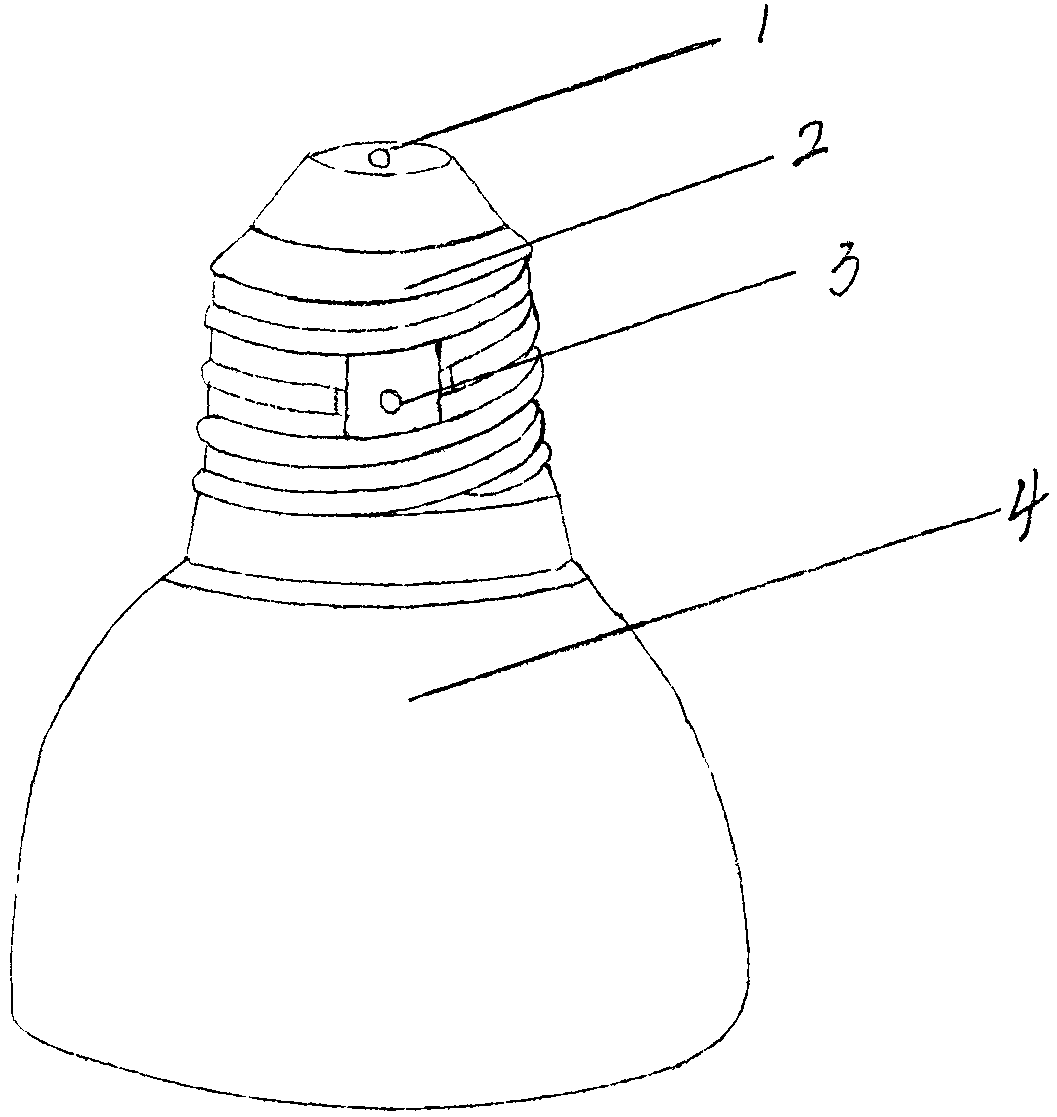

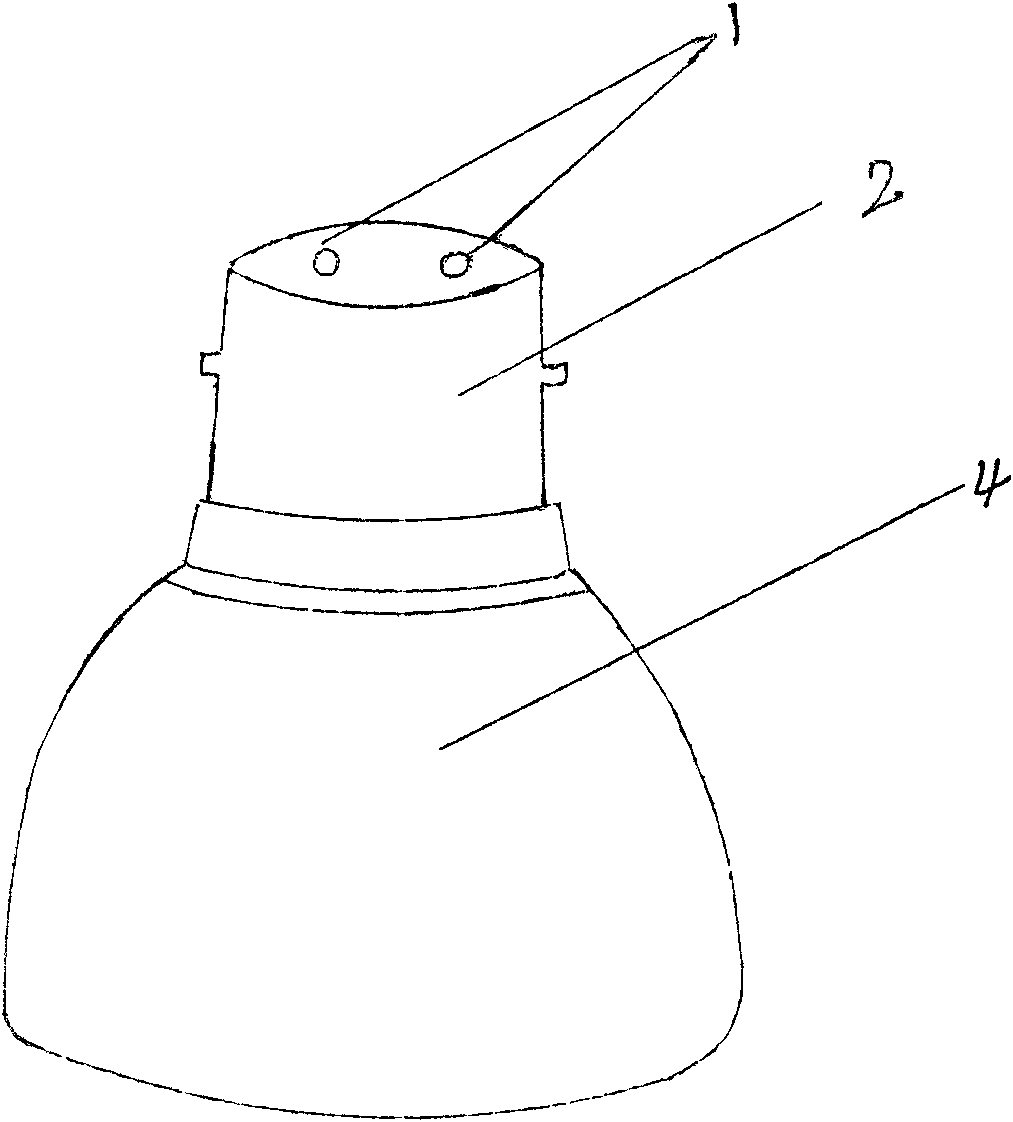

[0012] Further illustrate the specific embodiment of the present invention below in conjunction with accompanying drawing

[0013] The key technology of the present invention is to directly combine the lamp holder and the upper plastic parts of the energy-saving lamp with each other, so in the specific implementation, only one injection mold can be installed to directly combine the lamp holders of various types and the upper plastic parts. , the plastic lamp cap after injection molding is very simple in production and operation. For the E-type lamp cap, because its principle is a spiral type, the upper point and the side point are connected to the power connection point, so only It is necessary to pass one wire on the circuit board through the small hole at the top of the lamp head and rivet it, and the other wire should pass through the small hole on the waist of the lamp head and rivet it, thus completing the wire The operation process of connecting with the lamp head; simil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com