Cable mechanical de-icing device

A technology for cable machinery and deicing wheels, which is applied in the installation of cables, motor vehicles, electrical components, etc., can solve the problems of inconvenient operation and complex structure, and achieve the effects of convenient portability, simple operation and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

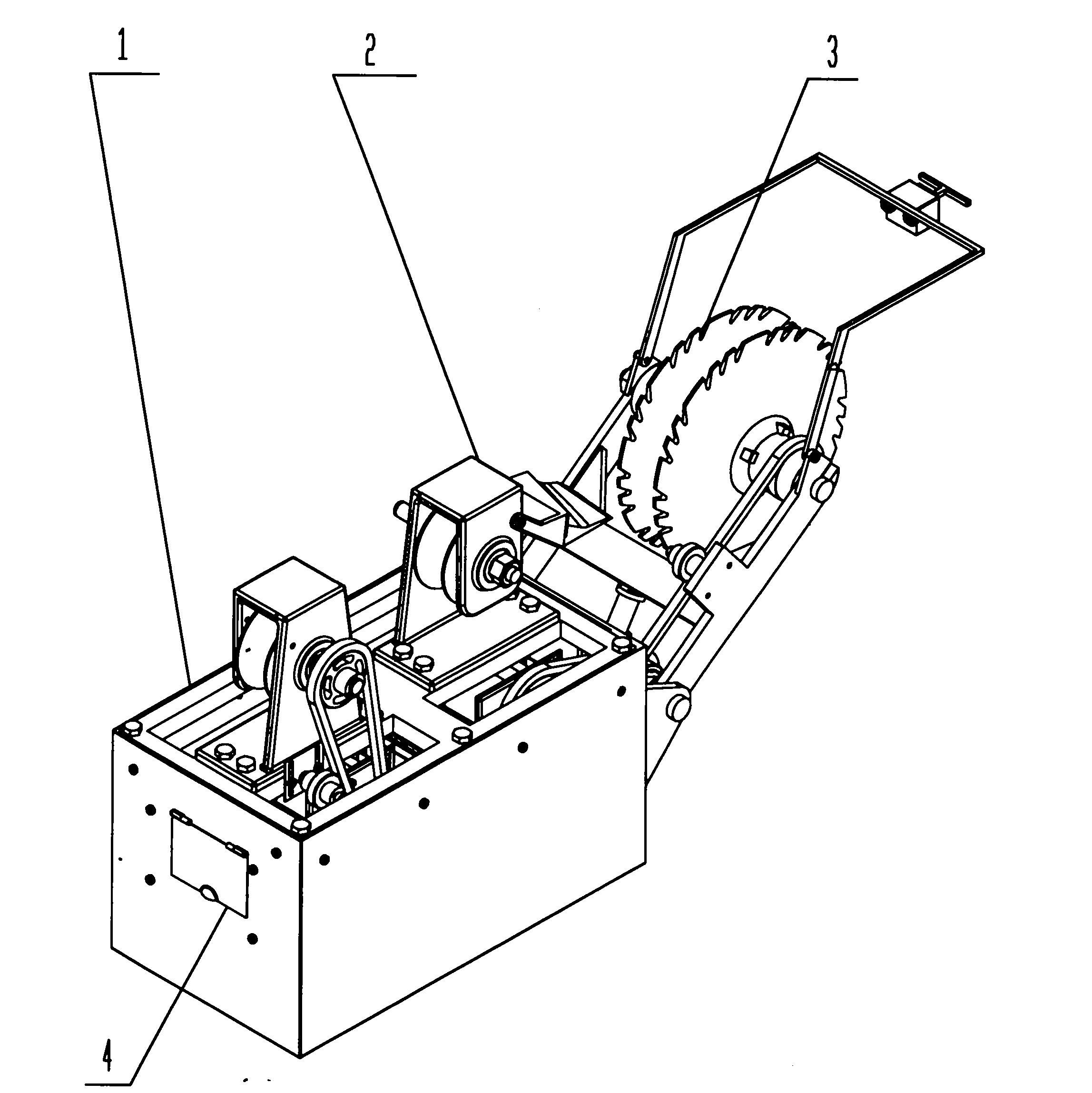

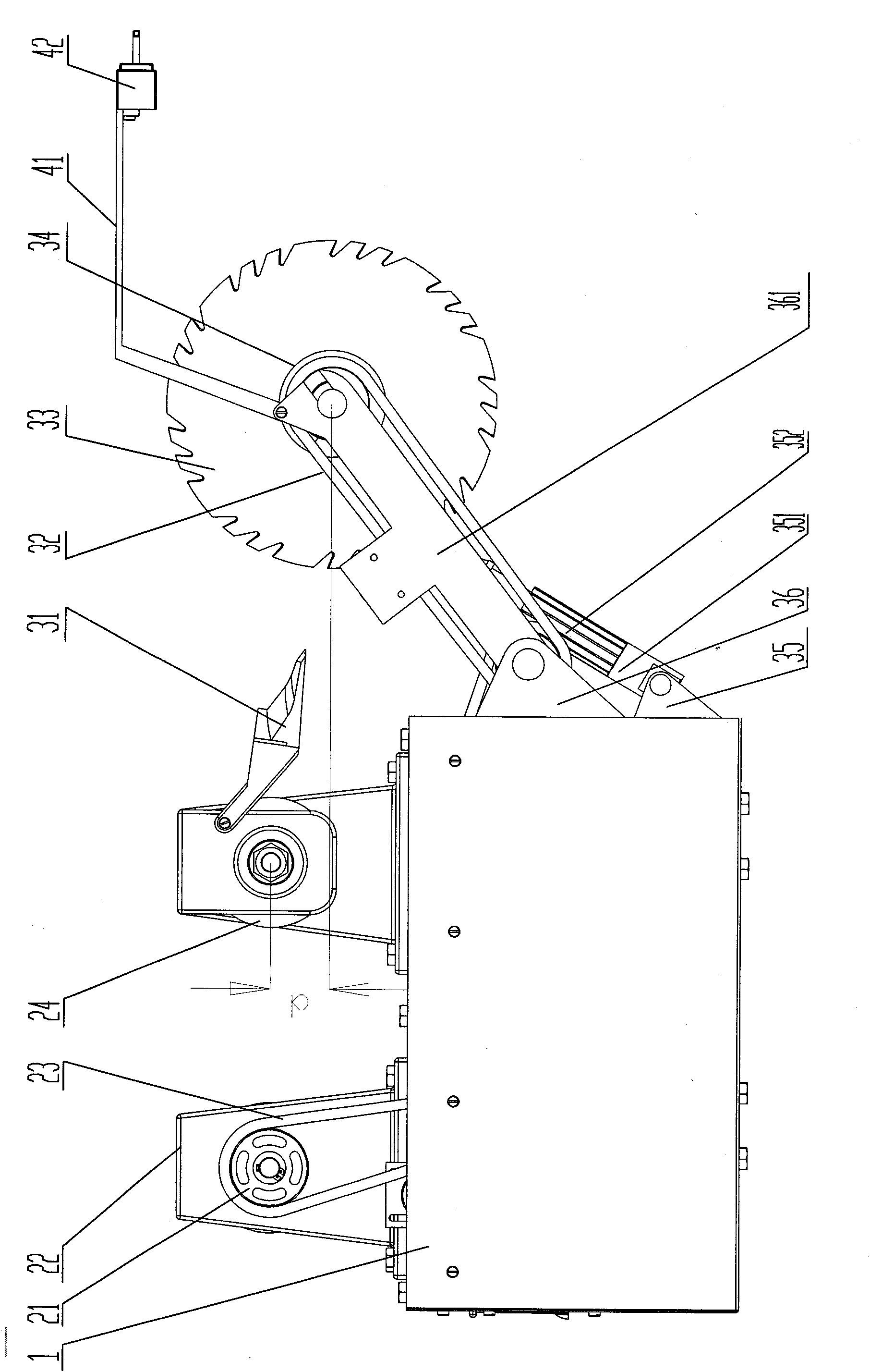

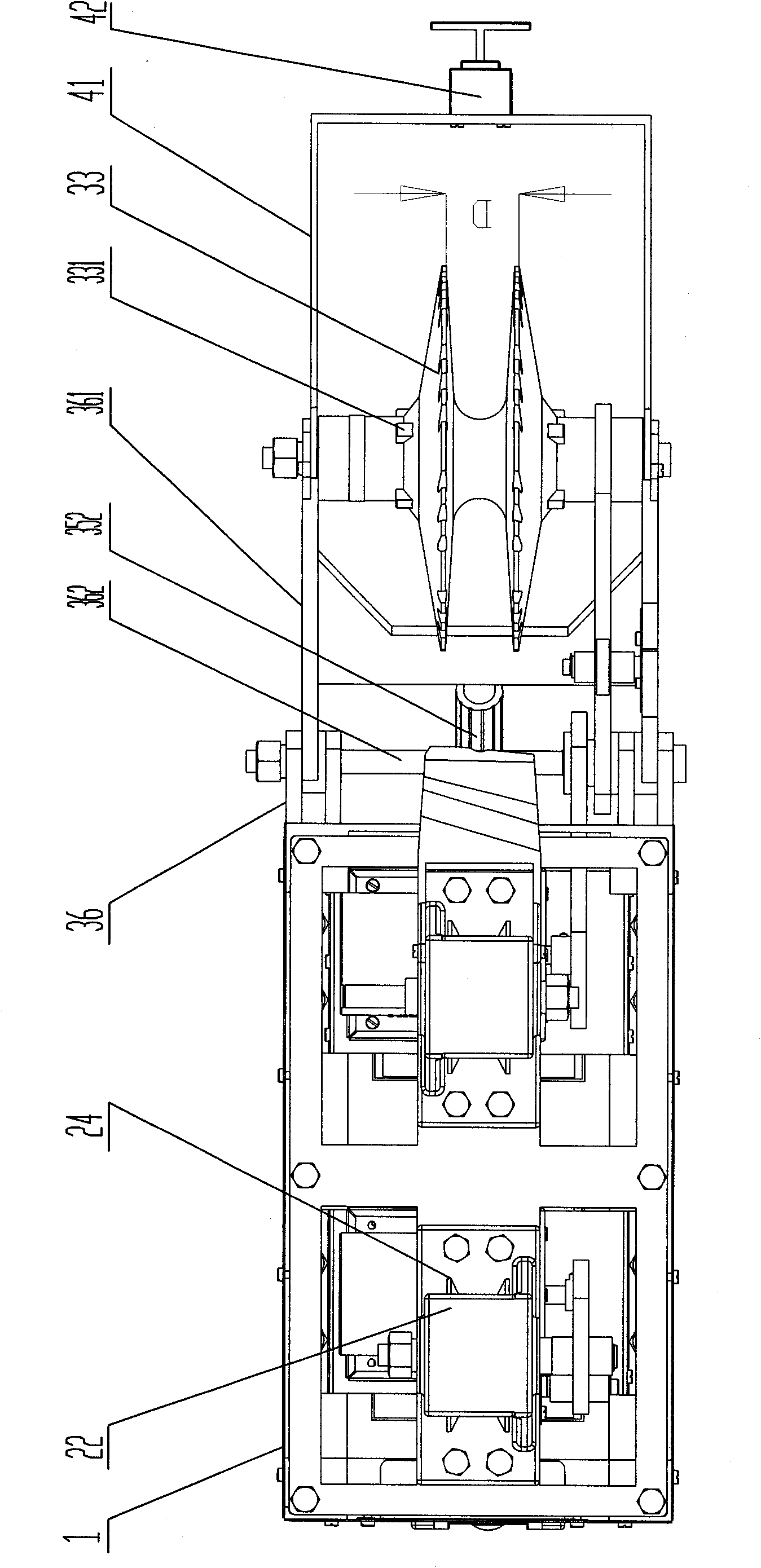

[0029] The overall structure of the embodiment of the cable mechanical deicing device is as follows: Figures 1 to 4 As shown, it includes a main body frame 1, a running mechanism 2, a deicing mechanism 3, a power mechanism and a control mechanism 4.

[0030] Described walking mechanism comprises hanger 22, road wheel 24, road wheel shaft and road chain wheel 21, and main frame 1 is the frame of cuboid. like Figure 5Shown, 2 front and rear hangers 22 are vertically fixed on the top surface of the main frame 1 through bolts, and 1 pair of walking wheel shafts and walking wheels 24 are installed on each hanger 22 . The walking wheel axle is rotatably installed on the hanger 1 through the bearing, and the walking wheel 24 is fixedly installed on the walking wheel axle by a key. The walking wheel axles on the front and back 2 hangers 22 are parallel. The traveling wheel 24 is a V-shaped grooved wheel, the front and rear 2 traveling wheels 24 are identical and the center planes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com