Battery monomer voltage measuring circuit and compensation method for measuring error thereof

A technology for measuring circuit and monolithic voltage, applied in the direction of measuring electric variable, measuring electricity, voltage/current isolation, etc., can solve the problems of high cost, low accuracy of voltage measurement, difficulty in large-scale promotion and application, etc., to meet the requirements of The need for installation space restrictions, the effect of solving electromagnetic compatibility and high voltage insulation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is further described

[0019] (1) Circuit and principle

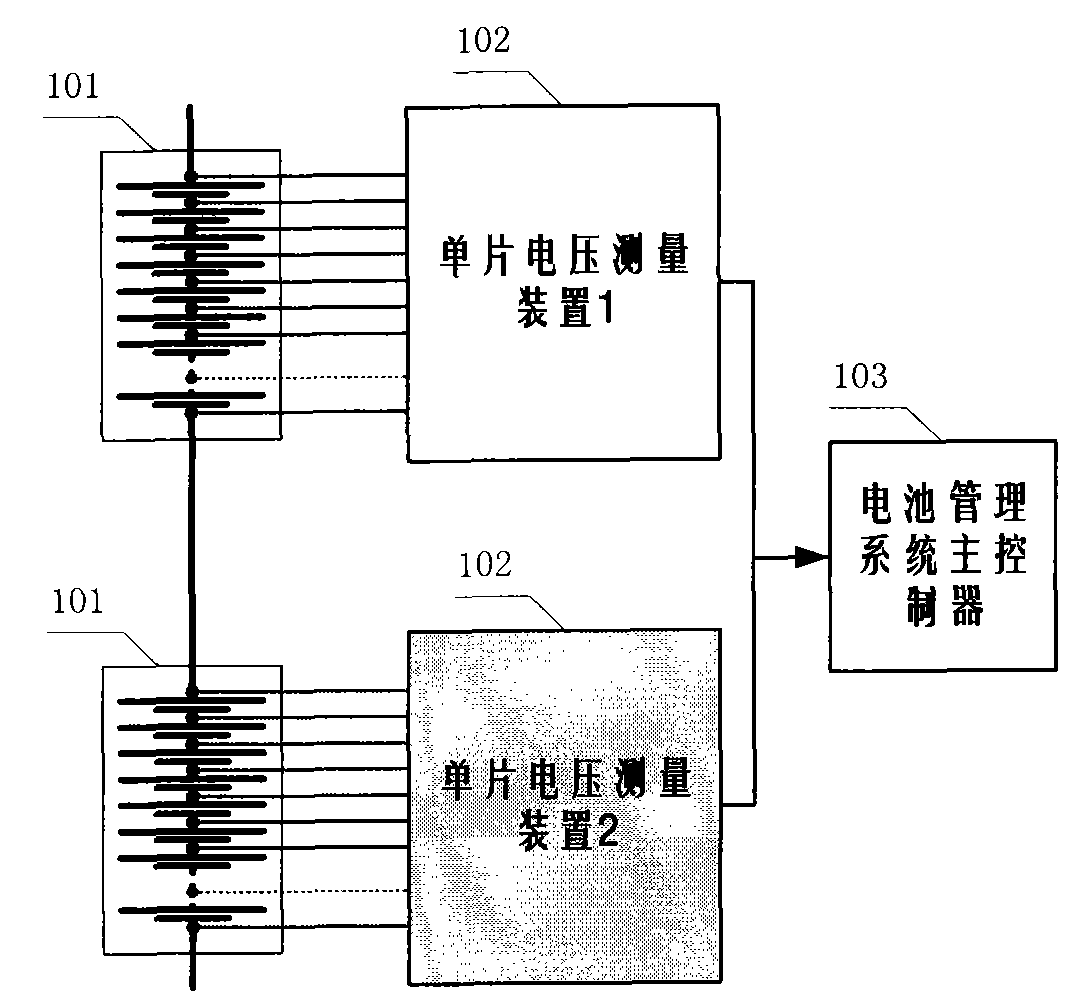

[0020] figure 1 Each battery box 101 is equipped with a set of this circuit 102. When there are multiple battery boxes, each measurement circuit can communicate with the main controller of the battery management system through the CAN bus, and the measured The battery voltage is sent to the main controller.

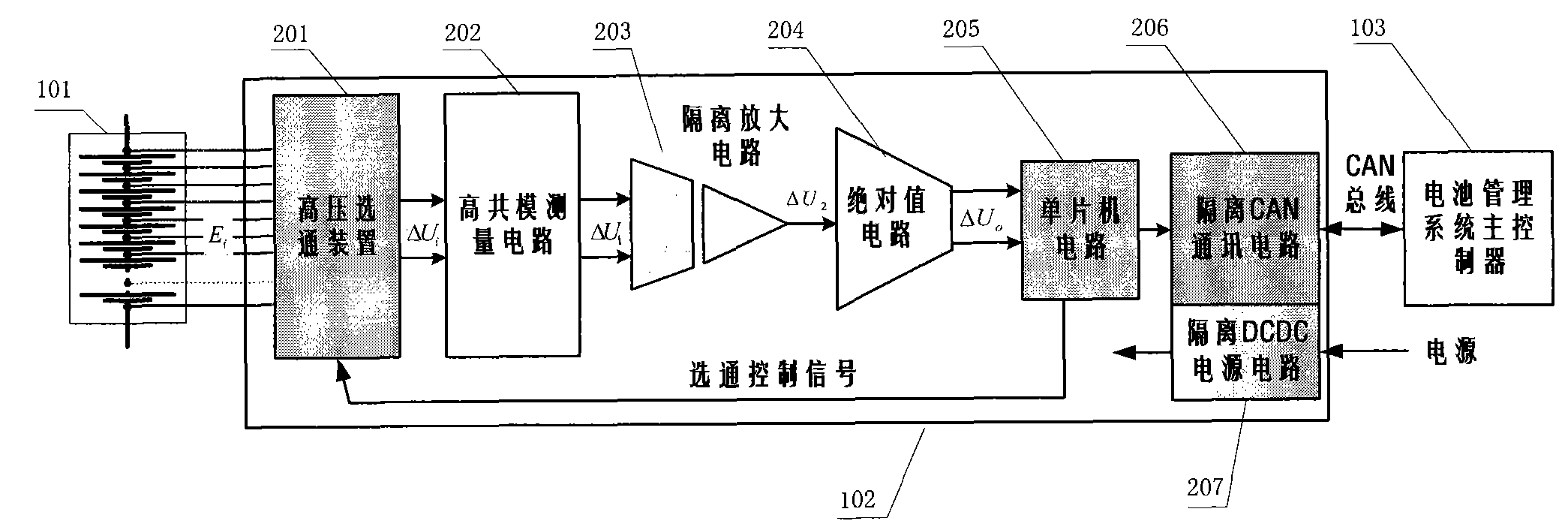

[0021] figure 2 It is a structural diagram of a battery single-chip voltage measurement circuit, including a high-voltage gating circuit 201 for gating a single-chip battery, a high common-mode measurement circuit 202, an isolation amplifier 203, an absolute value output circuit 204, a single-chip circuit 205, a communication circuit 206 and an isolation DCDC power supply 207 . The isolated power supply outputs the 5V power supply required by the microcontroller, and the ±15V power supply required by the common-mode diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com