Method for realizing rapid optical cable termination by adopting standardized terminal fitting

A terminal connector, standard optical fiber technology, applied in the field of communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

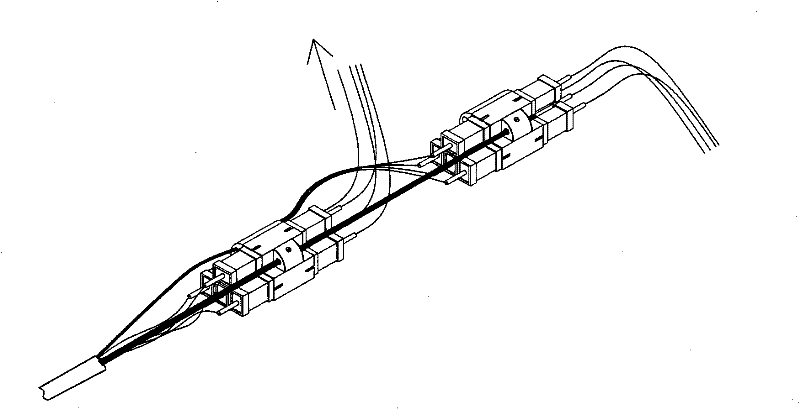

[0028] see figure 1 , the method for quickly terminating an optical cable of the present invention adopts an optical cable section with a joint, and cooperates with a terminal optical fiber connector through a standardized optical fiber joint at both ends of the optical cable section to realize rapid connection of the optical cable.

[0029] Wherein, the optical cable section with joints is provided with standardized optical fiber joints connected to the fiber core at both ends of the common optical cable section. Standardized optical fiber connectors can be selected to use SC connectors, FC connectors or LC connectors as required. Typical values such as 500 meters, 1000 meters, 1500 meters and 2000 meters are used for the cable section.

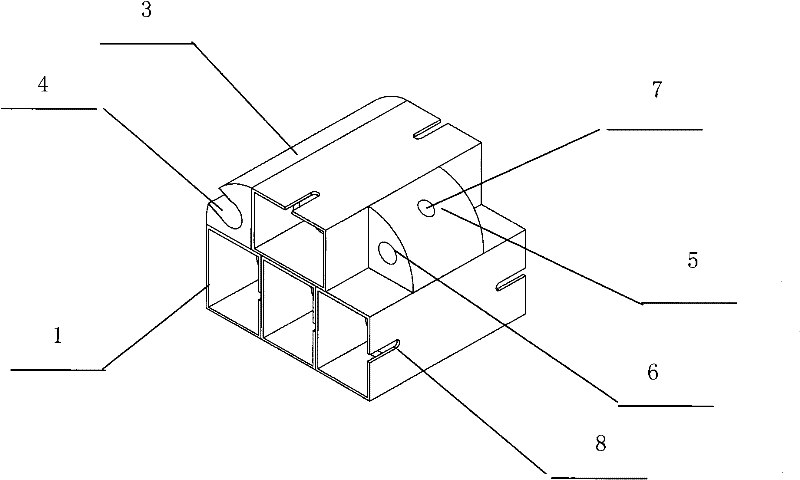

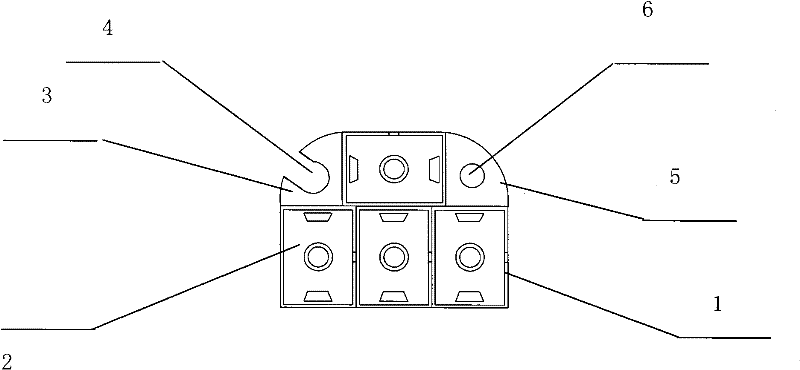

[0030] The above-mentioned terminal optical fiber connector includes two parts: a box body and a standard optical fiber connector fixedly arranged in the box body. Since the currently commonly used communication optical cables are 4, 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com