Filter element component and dust removal device therewith

A technology of dust removal device and filter element, which is applied in the field of dust removal device and filter element assembly, which can solve the problems that the filtering work cannot be completed, the filter element cannot be rotated, and cannot be cleaned, so as to achieve good cleaning effect, good dust removal effect and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

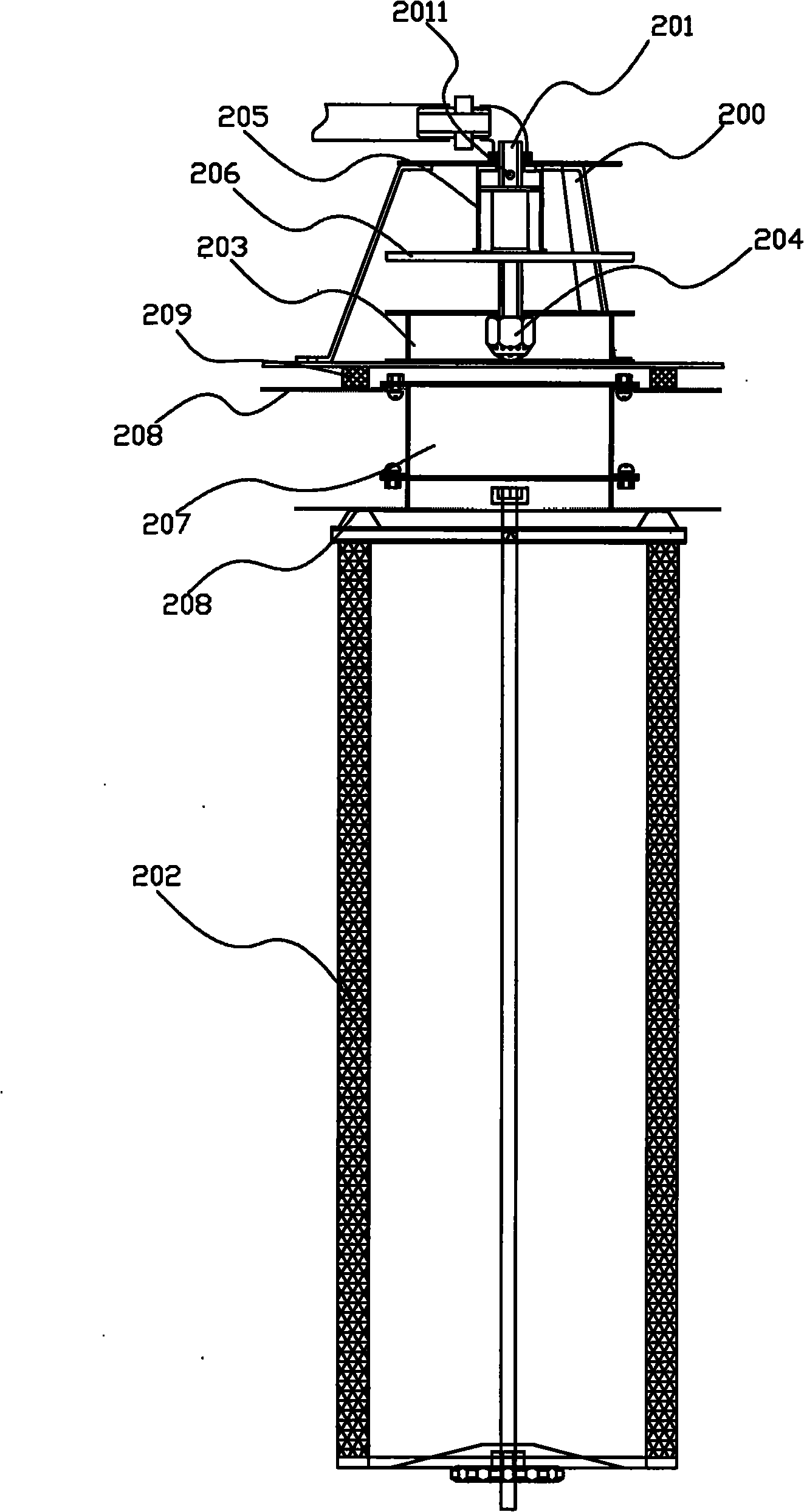

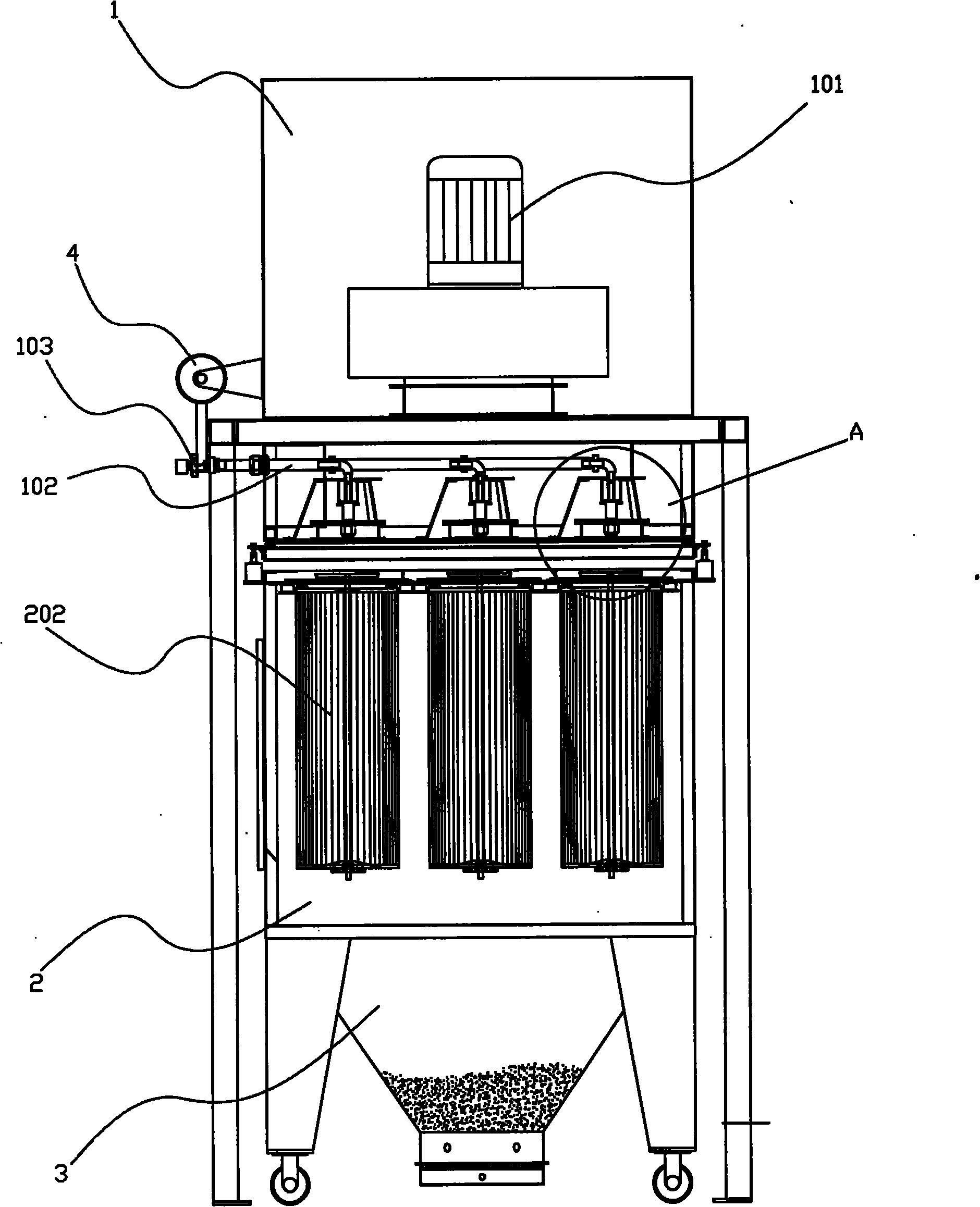

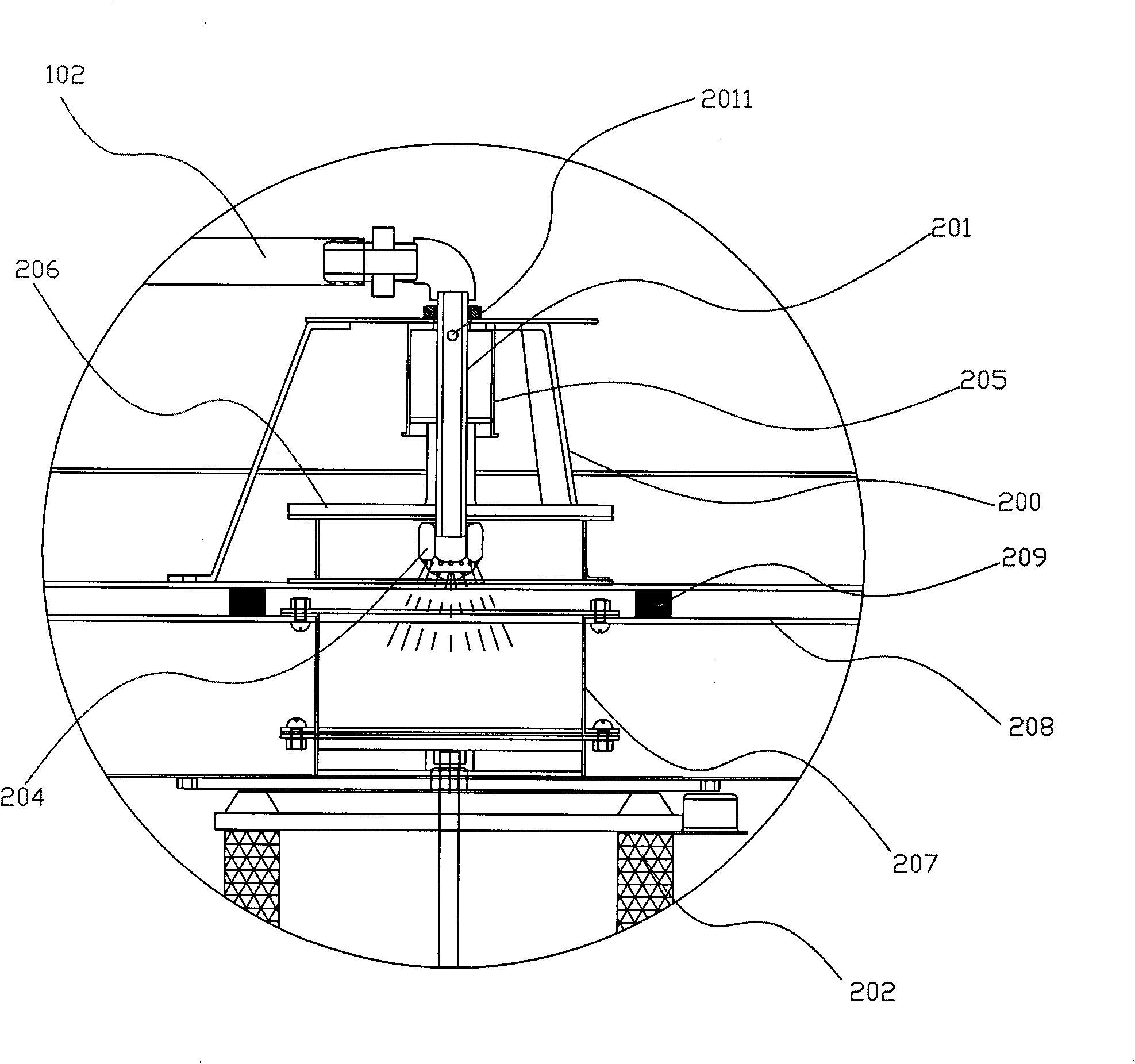

[0015] like figure 1 As shown, the present invention provides a filter element assembly, including a bracket warehouse 200, the upper side of the bracket warehouse 200 is provided with an air delivery shaft 201 connected to the air delivery pipe of the gas storage tank, and the filter element 202 is connected to the lower part through a sealed connection device. The lower part of 200 is provided with a section of closed cavity 203 connected with the sealing connection device, the lower end of the air transmission shaft 201 is provided with a pulse head 204, and the pulse head 204 is located in the closed cavity 203, and the bracket warehouse 200 is also provided with The cylinder 205 connected to the gas delivery shaft 201 , the piston end of the cylinder 205 is a lifting plate 206 that is combined with the edge of the closed cavity 203 below to seal the closed cavity 203 when the gas delivery shaft 201 is inhaled.

[0016] As a preferred embodiment, the air cylinder 205 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com