Improved structure of rotary engine

A technology to improve the structure and engine, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of exhaust gas removal, combustion and asphyxiation of carbon monoxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

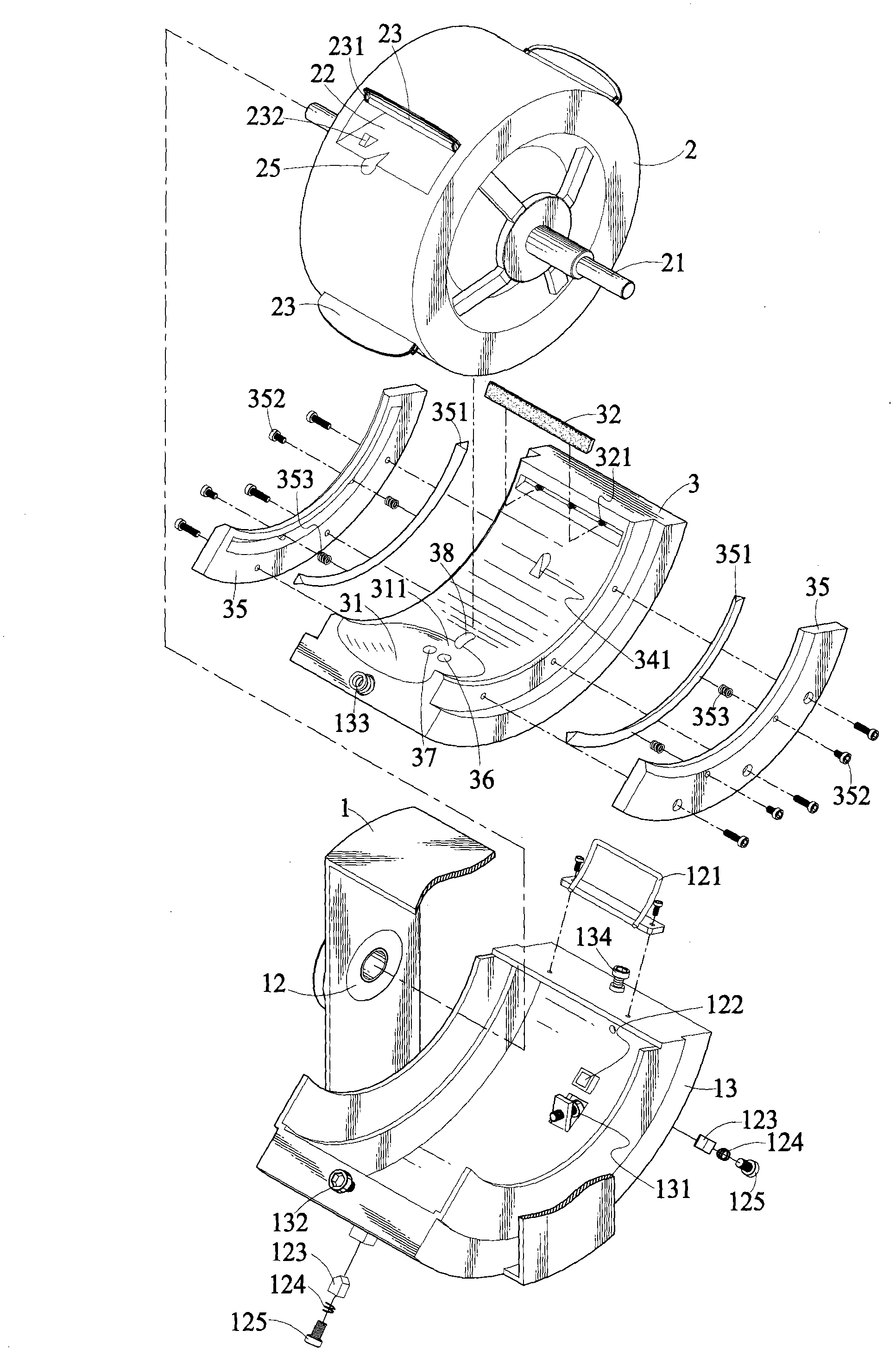

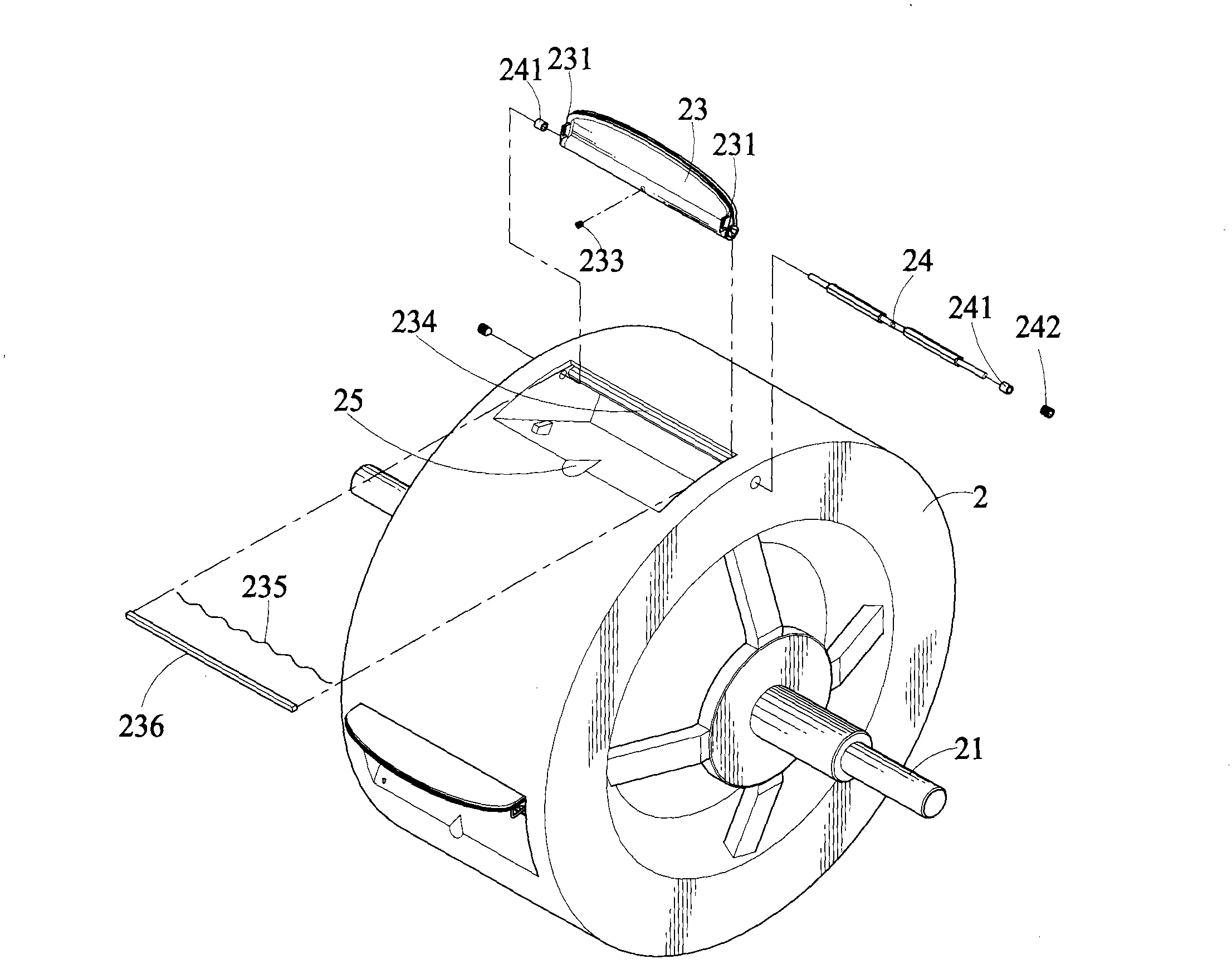

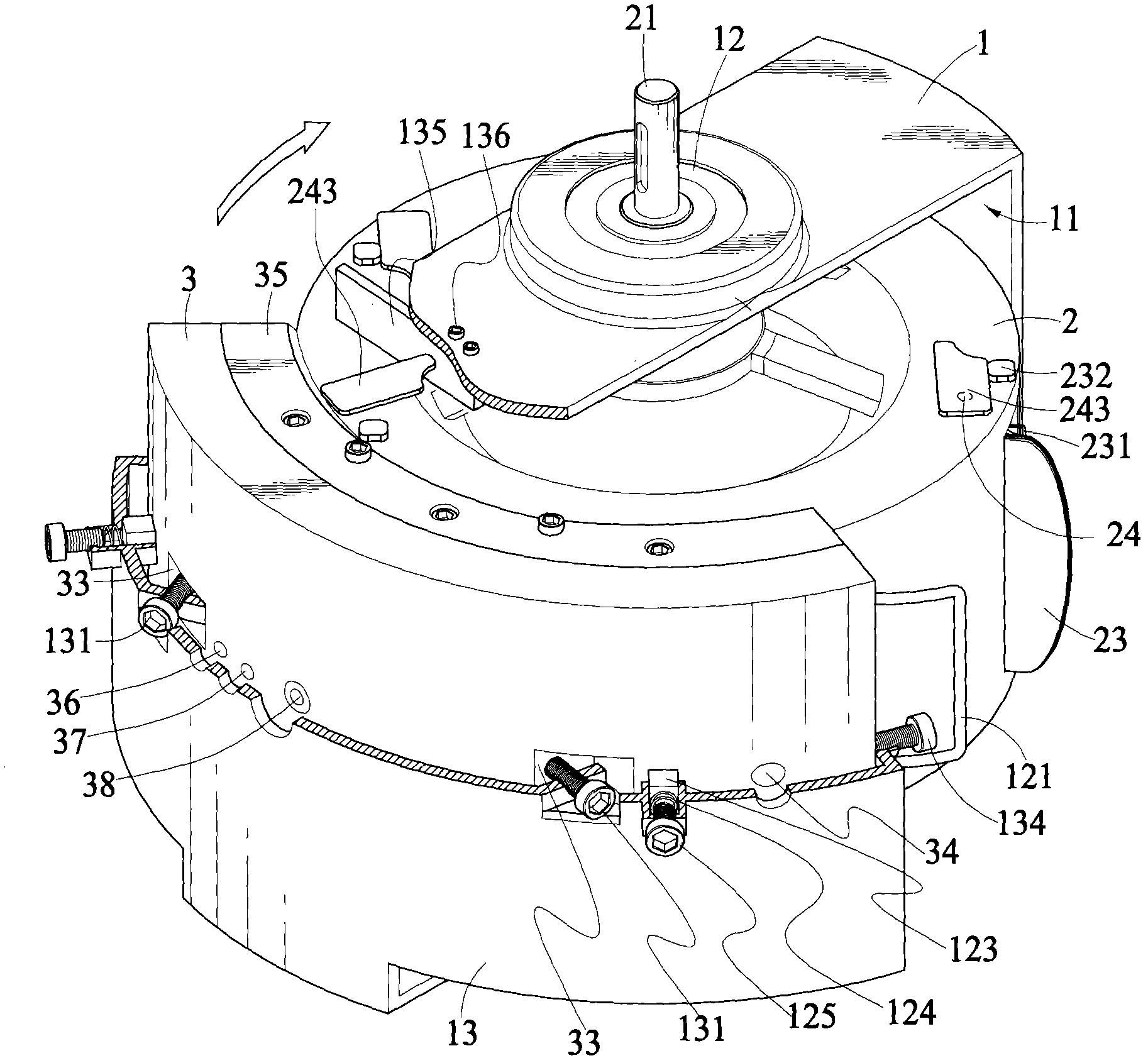

[0017] In order to make the content of the present invention clearly understood, only refer to the following descriptions with accompanying drawings Figure 1 to Figure 6 As shown, the present invention includes at least the following components:

[0018] A frame 1 in a frame shape has an accommodating space 11 formed in its center, a bearing 12 is provided at the center of the horizontal sections on both sides, and an arc-shaped housing 13 is provided on the vertical section of the frame 1. The front edge of the shaped housing 13 is provided with an arc-shaped guide plate 121 and a resisting screw 134, a plurality of adjustment screws 131 are arranged on the arc surface, and a set of positioning devices are respectively provided at the center of the two ends of the arc surface, which includes a square sleeve 122, A square bar 123 , a spring 124 and a pressure regulating screw 125 . In addition, a pressure regulating screw 132 and a spring 133 are provided on the end edge (ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com