Four-degree-of-freedom integrated robot joint mechanism

A technology of robot joints and degrees of freedom, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve the problems of complex and huge overall robot mechanism, and achieve the effect of improving integration and modularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

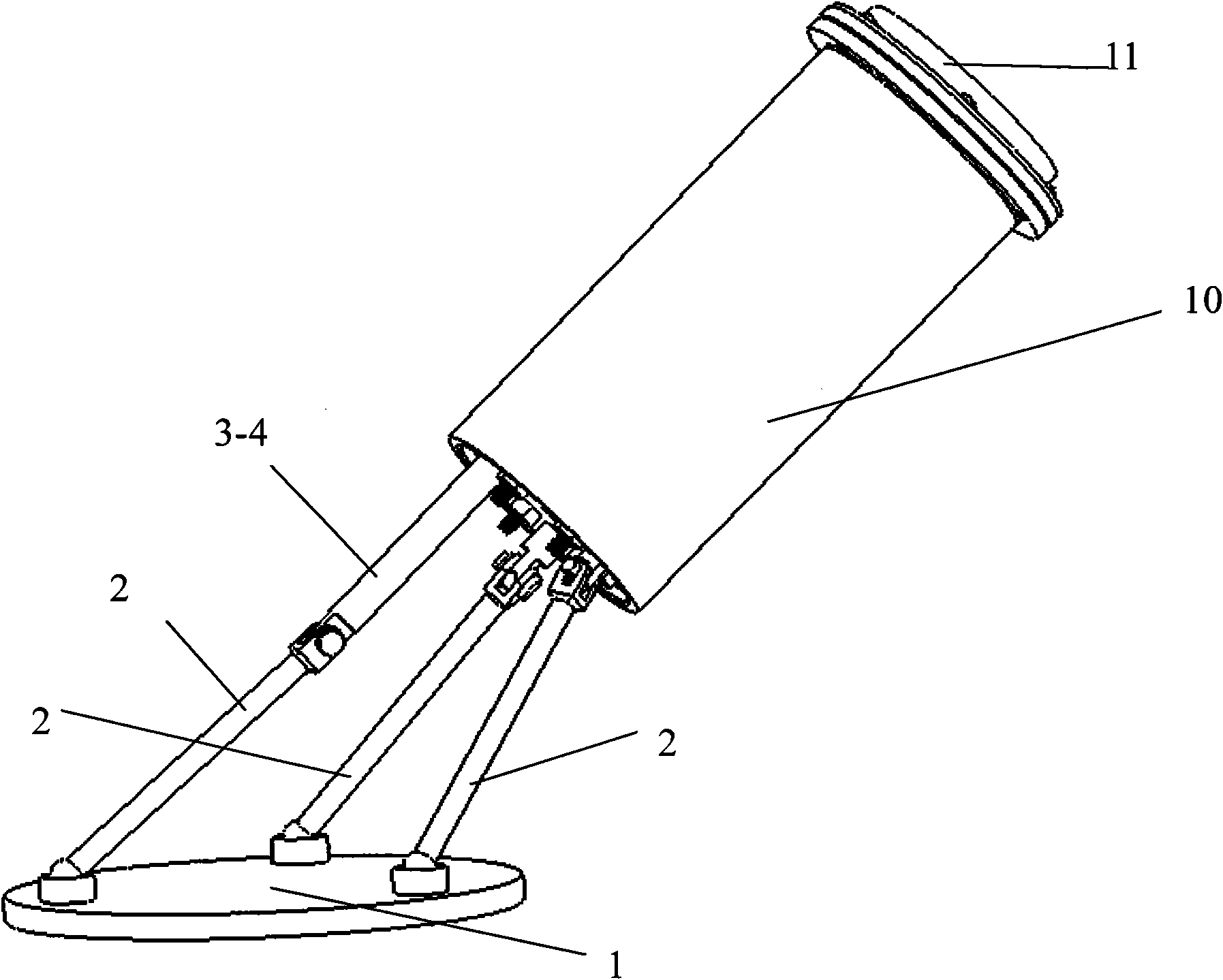

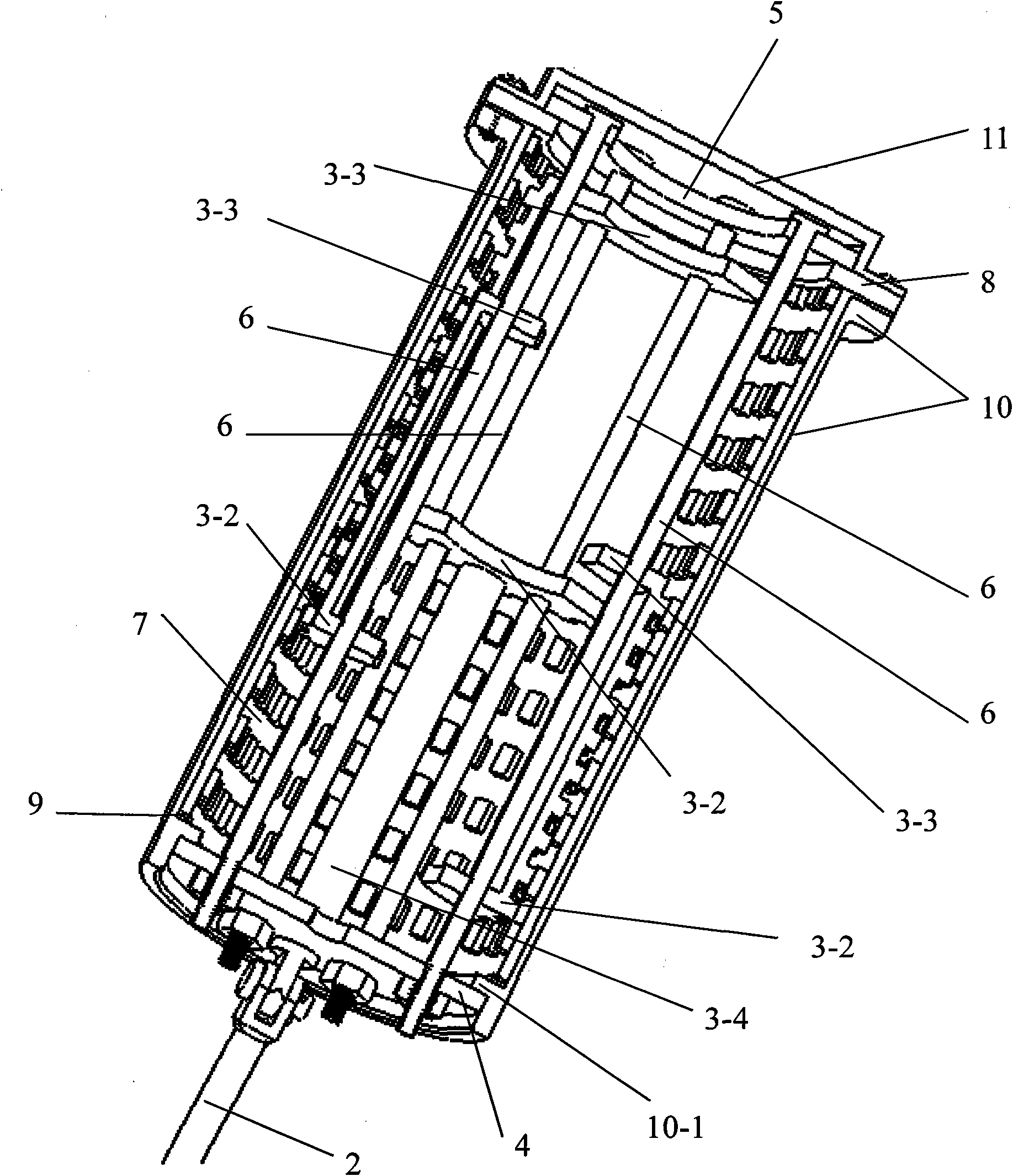

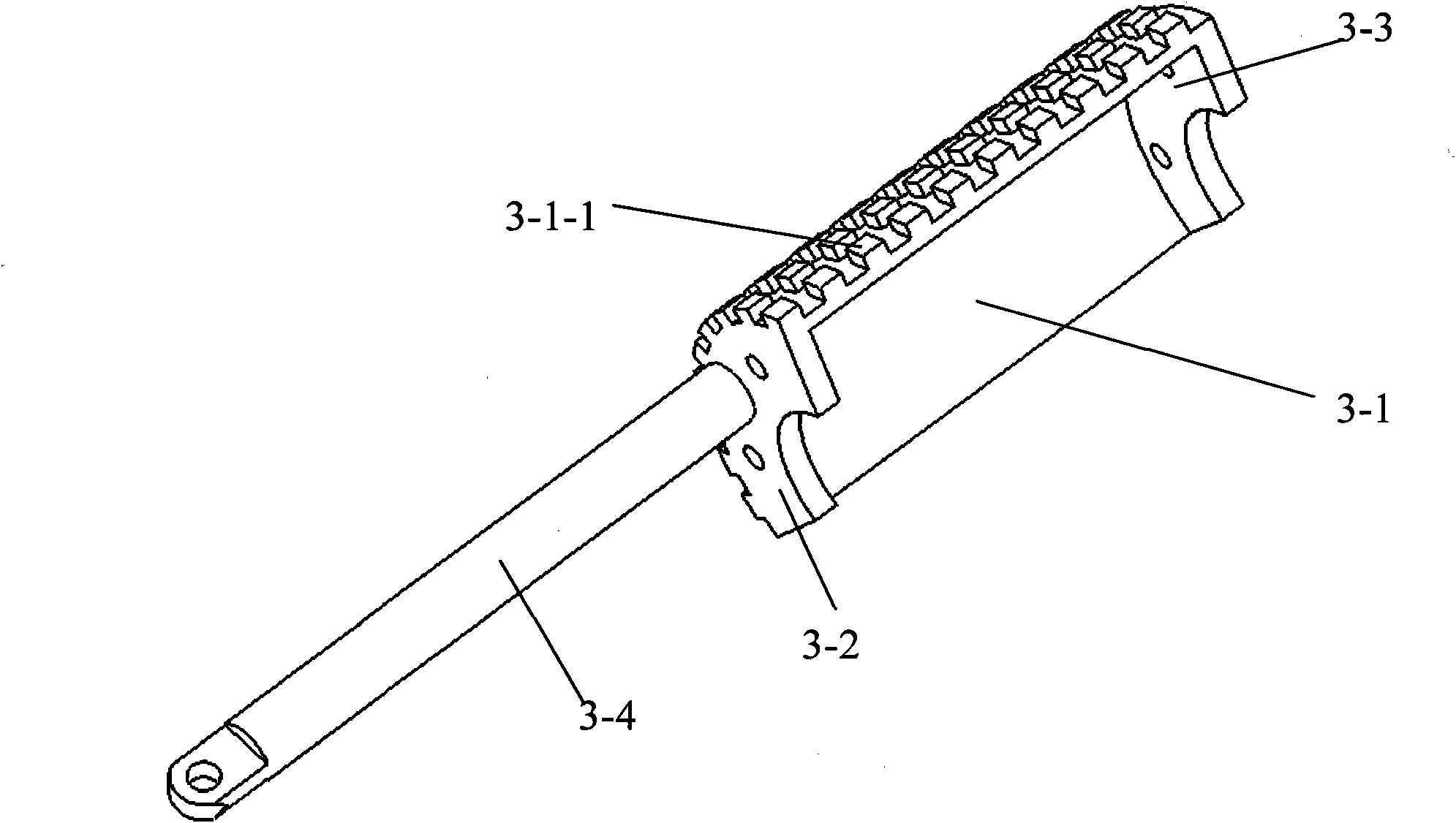

[0018] Specific implementation mode one: as Figure 1-7 As shown, a four-degree-of-freedom integrated robot joint mechanism described in this embodiment includes an end platform 1, a support body and a drive assembly, and the support body is composed of an end cover 11 and a first sliding plate 4 , the second sliding plate 5, six guide rods 6, retaining ring 8 and outer cylinder body 10 constitute; the drive assembly includes drive cylinder 7, three drivers 3 and three connecting rods 2; each driver 3 consists of Cylindrical curved driver main body 3-1, first end plate 3-2, second end plate 3-3 and driver extension rod 3-4 are formed, cylindrical curved driver main body 3-1, first end The plate 3-2 and the second end plate 3-3 constitute the cylinder part of the driver; the inner surface of the drive cylinder 7 of the joint mechanism is provided with a lattice winding (coil) 7-1, and the cylindrical curved surface driver body 3- The outer surface of 1 is provided with a latti...

specific Embodiment approach 2

[0022] Specific implementation mode two: as figure 2 As shown, the joint mechanism of this embodiment also includes a rubber ring 9, and the rubber ring 9 is sandwiched between the corresponding end surface of the outer cylinder body 10 and the inner end surface of the flange 10-1, and the rubber ring 9 and the outer cylinder body flange inside contact. The rubber ring can ensure the reliability of the installation and fixation of the drive cylinder. Other components and connections are the same as those in the second embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: In this embodiment, the outer surfaces of the first sliding plate 4 and the second sliding plate 5 are provided with a layer of polytetrafluoroethylene coating, so as to reduce friction and enhance smoothness of rotation. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com