Pressure water storage barrel

A water storage tank and pressure technology, applied in the direction of osmosis/dialysis water/sewage treatment, etc., can solve the problems of potential safety hazards, high production cost of pressure water storage tanks, and existing problems in the pure water machine system, and achieve the goal of reducing requirements and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

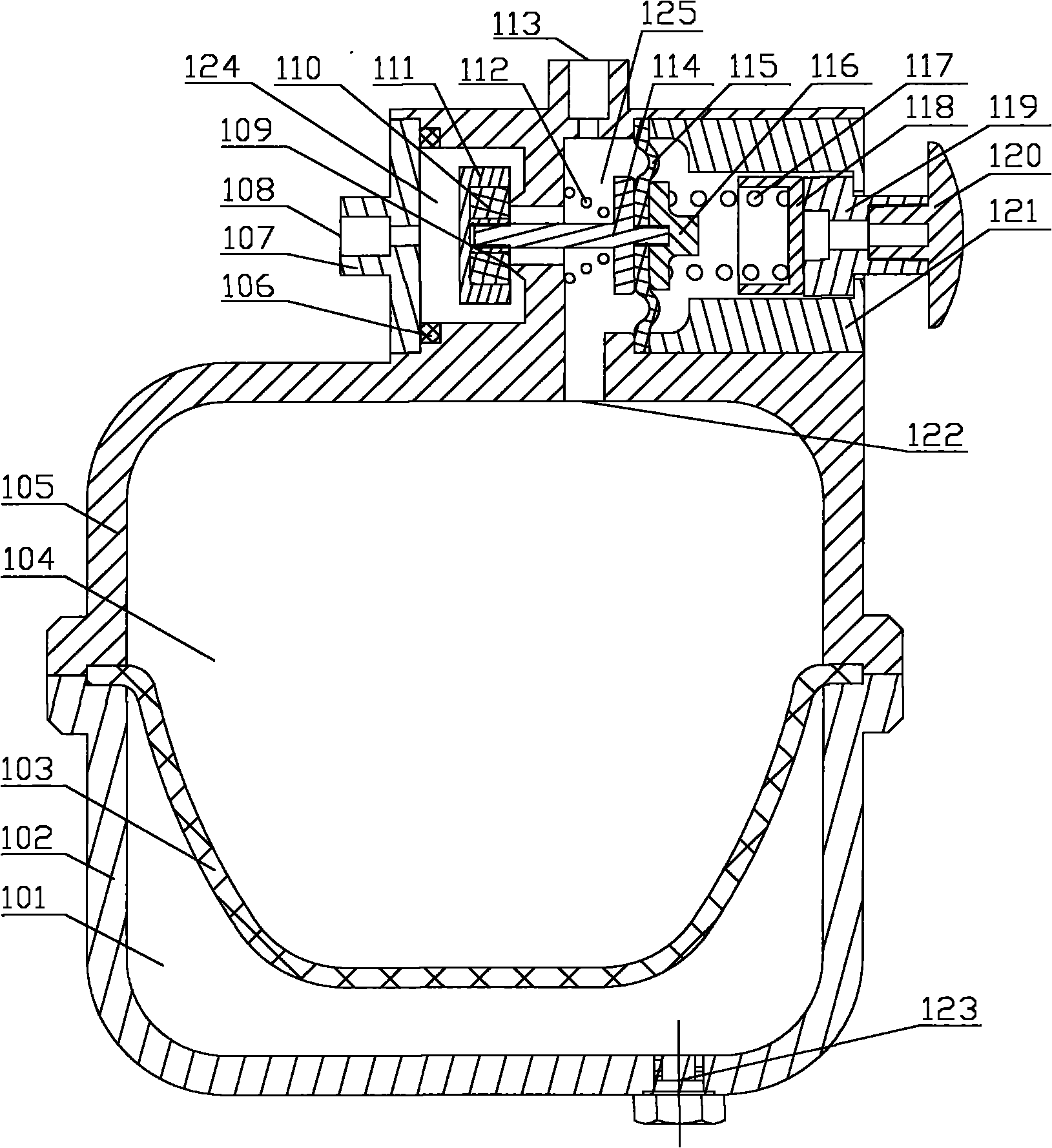

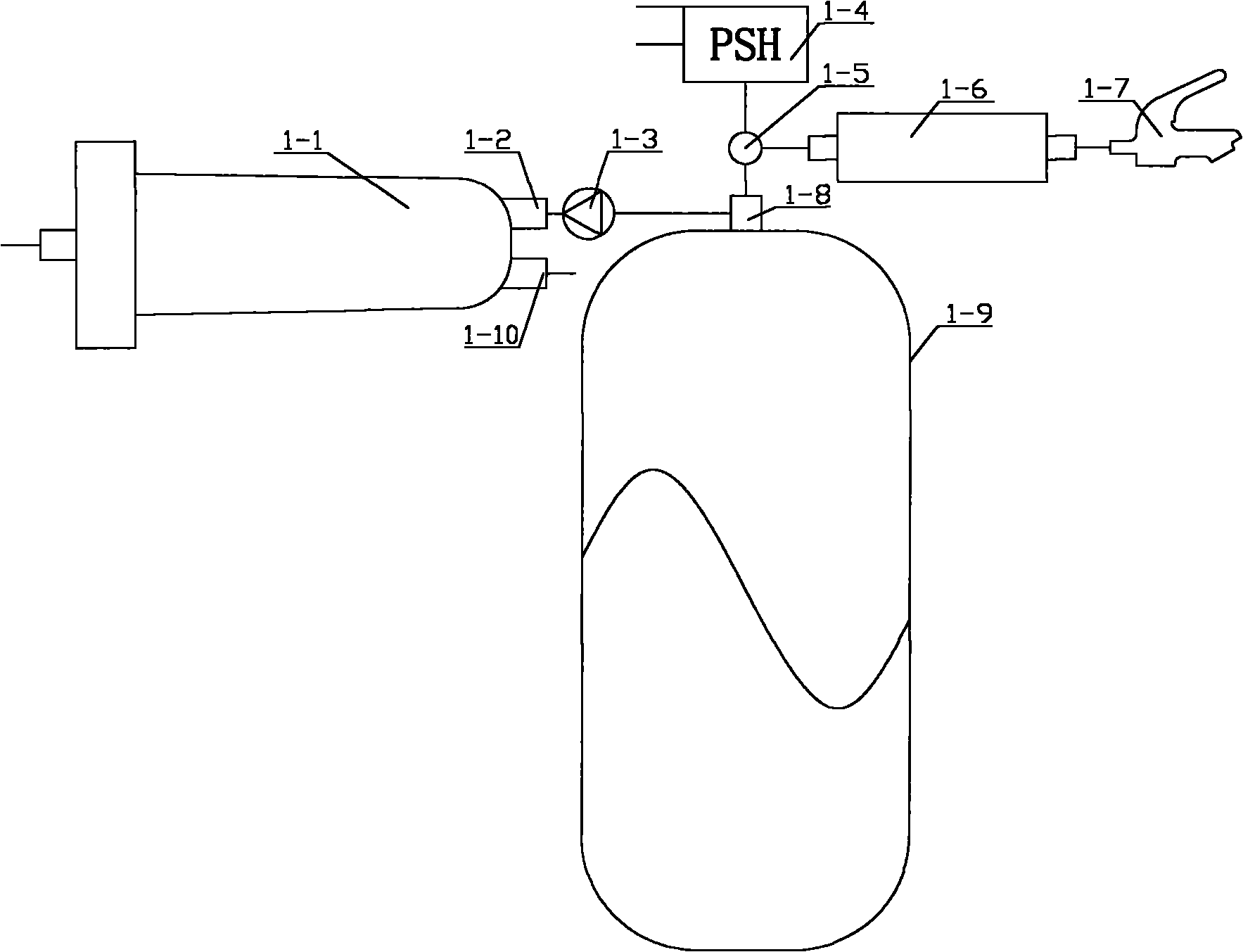

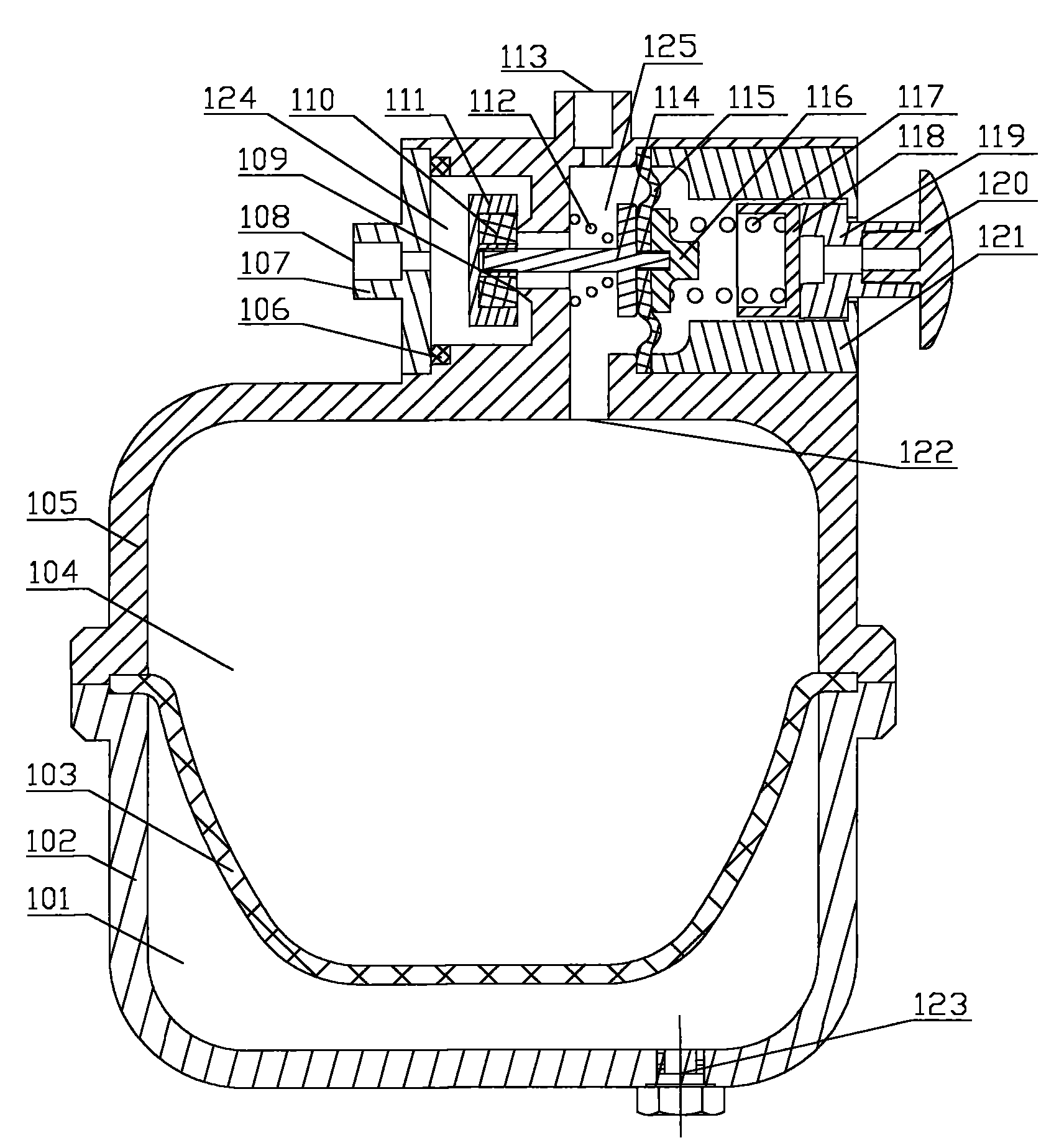

[0012] see figure 1 , figure 2 As shown, the pressure water storage barrel of this embodiment includes a barrel body with an internal cavity, and the barrel body is composed of an upper cover 105 and a lower cover 102 sealed and connected, and a flexible diaphragm 103 is pressed and fixed between the upper cover 105 and the lower cover 102, The flexible diaphragm 103 separates the inner cavity of the barrel body into a clean water chamber 104 and an air chamber 101, and the pressure water storage barrel body is provided with a pressure limiting component, and the pressure limiting component is integrated on the pressure water storage barrel body and the pressure water storage barrel body is Integral structure; the pressure limiting assembly provided on the pressure water storage barrel body includes a water inlet chamber 124 and a water outlet chamber 125 formed by the upper cover body outside the water purification chamber 104, and the water inlet chamber 124 is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com