Turbofan postpose type engine

A turbojet engine and rear-mounted technology, applied in the direction of machines/engines, jet propulsion devices, etc., can solve problems such as complex manufacturing and processing, high cost, and difficult design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

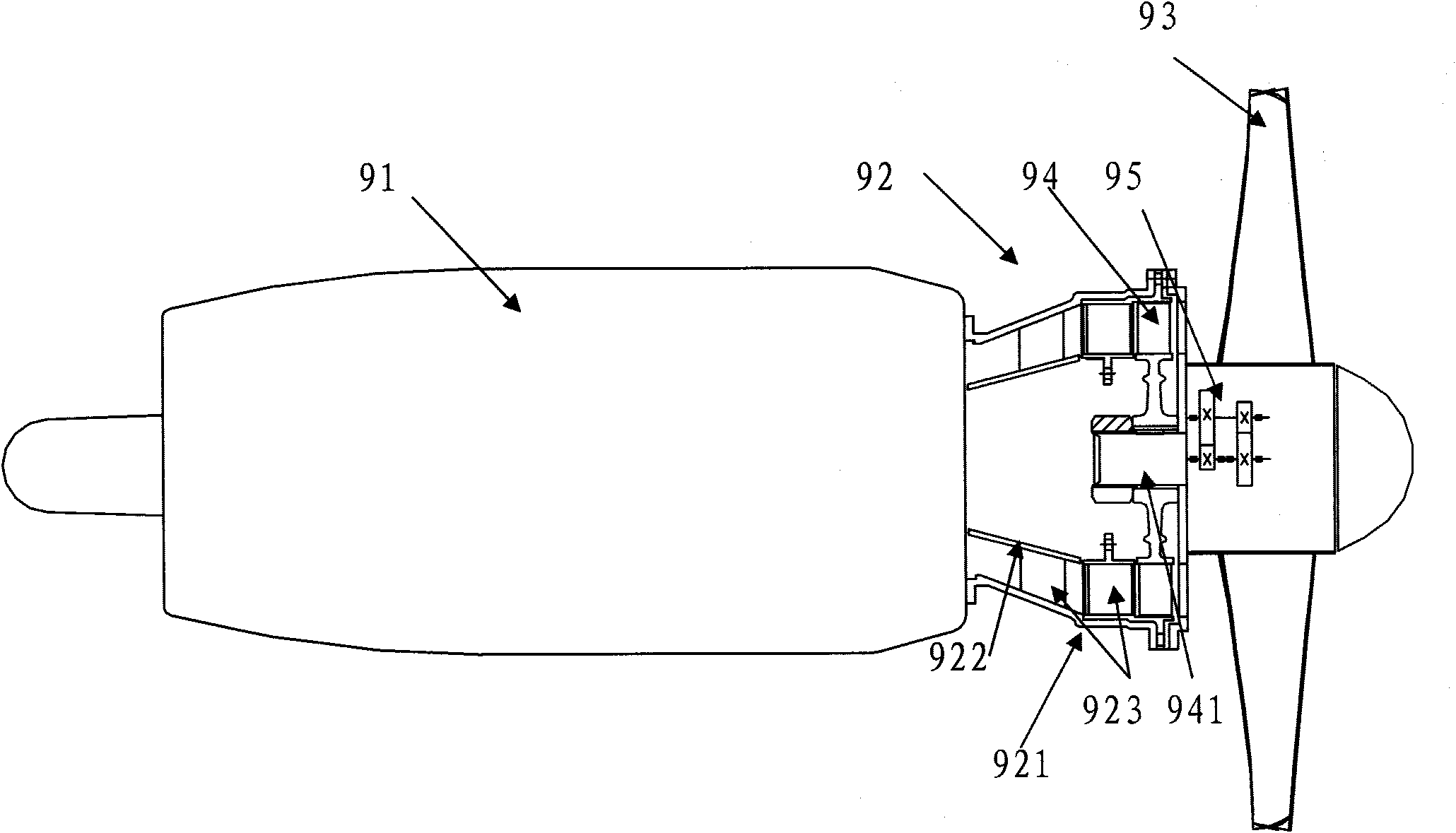

[0027] like figure 1 Shown, the turbofan rear-mounted engine of the present invention at least includes:

[0028] One turbojet engine 91, in order to provide power;

[0029] The converter 92 is installed at the jet port behind the turbojet engine to convert the high-temperature, high-pressure, and high-speed airflow of the turbojet engine into the rotational power of the free turbine;

[0030] A free turbine 94 is installed at the gas outlet of the converter, and a speed reducer 95 is installed at the rear end of the shaft of the free turbine;

[0031] The fan 93 is connected on the power output shaft of the speed reducer. The fan can be set in one or more stages as required.

[0032] With the above-mentioned rear fan structure, the reducer and the fan are installed on the free turbine shaft at the rear of the converter, which is generated by the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com