Multi-layer rubber sealing ring sealing device

A technology of rubber sealing ring and sealing device, which is applied in the direction of engine sealing, engine components, pressure vessel/vacuum vessel, etc., can solve the problems of vacuum cavity pollution and other problems, and achieve good anti-leakage performance, anti-leakage and long service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

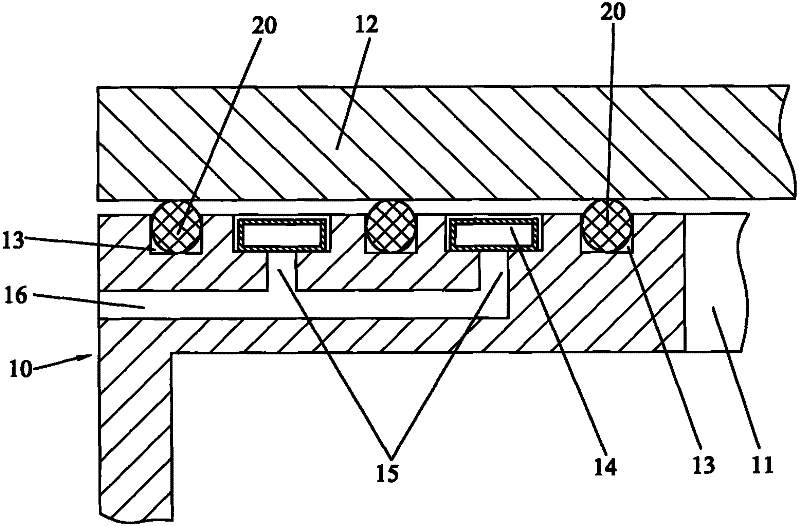

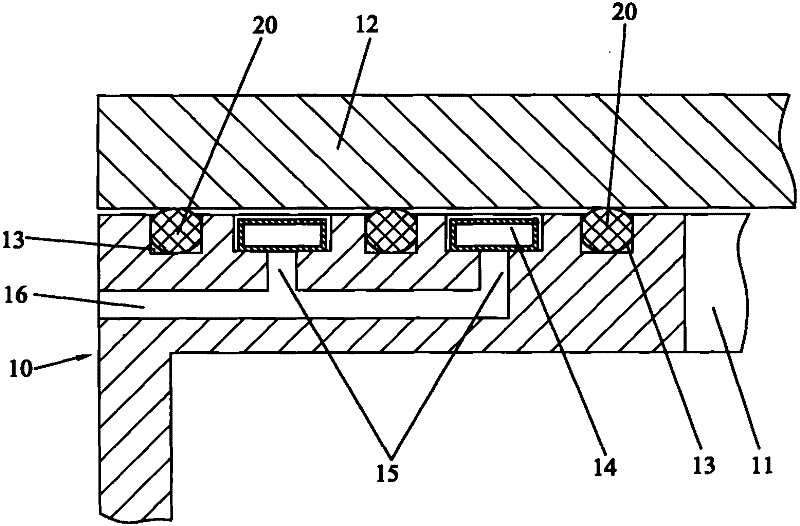

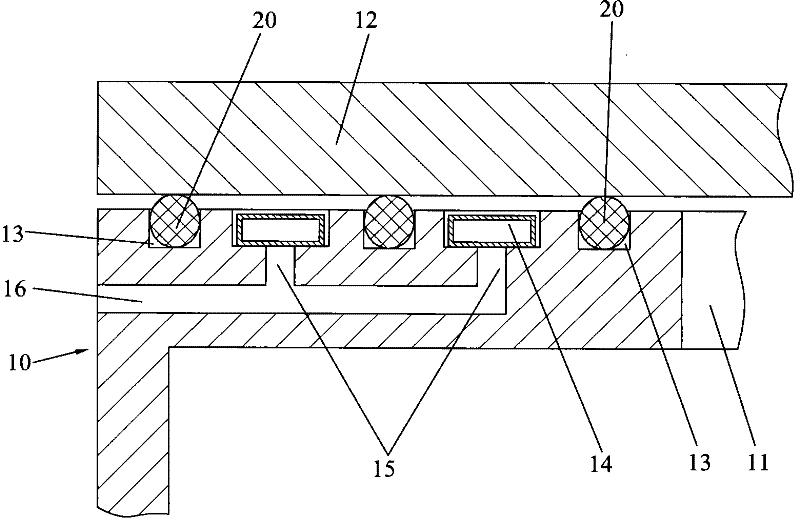

[0010] Such as figure 1 and figure 2 As shown, the multi-layer rubber sealing ring sealing device of the present invention is suitable for sealing the connection between the cavity mouth 11 of the vacuum chamber 10 and the chamber cover 12, and the multi-layer rubber sealing ring sealing device includes several rubber sealing rings 20, The vacuum cavity 10 facing the cavity cover 12 is provided with an accommodating groove 13 surrounding the cavity opening 11, and the rubber sealing rings 20 are accommodated in the accommodating groove 13 one by one and protrude In the accommodating tanks 13, cooling tanks 14 facing the chamber cover 12 are opened between adjacent accommodating tanks 13, and the cooling tubes 15 in a hollow structure are accommodated in the cooling tanks 14 one by one. , the side wall of the vacuum cavity 10 is also provided with a pumping channel 16, one end of the pumping channel 16 communicates with an external vacuum device, and the other end of the pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com