Quantitative tension and compression testing device

A test device, test piece technology, applied in the direction of testing the strength of materials by applying stable tension/pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

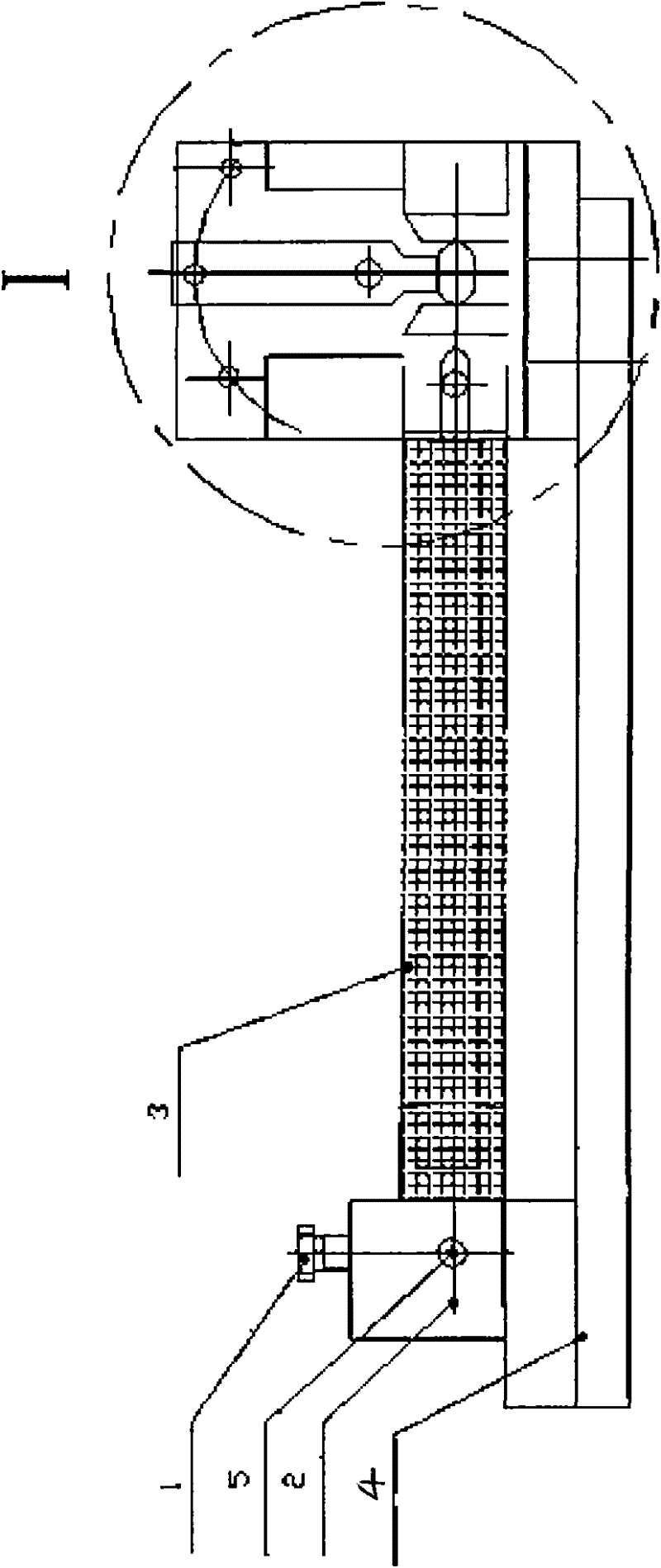

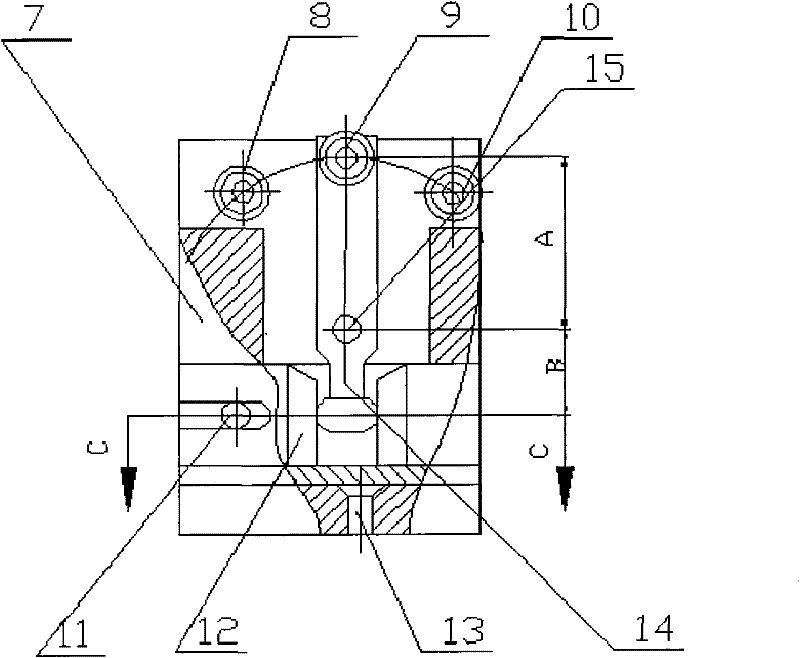

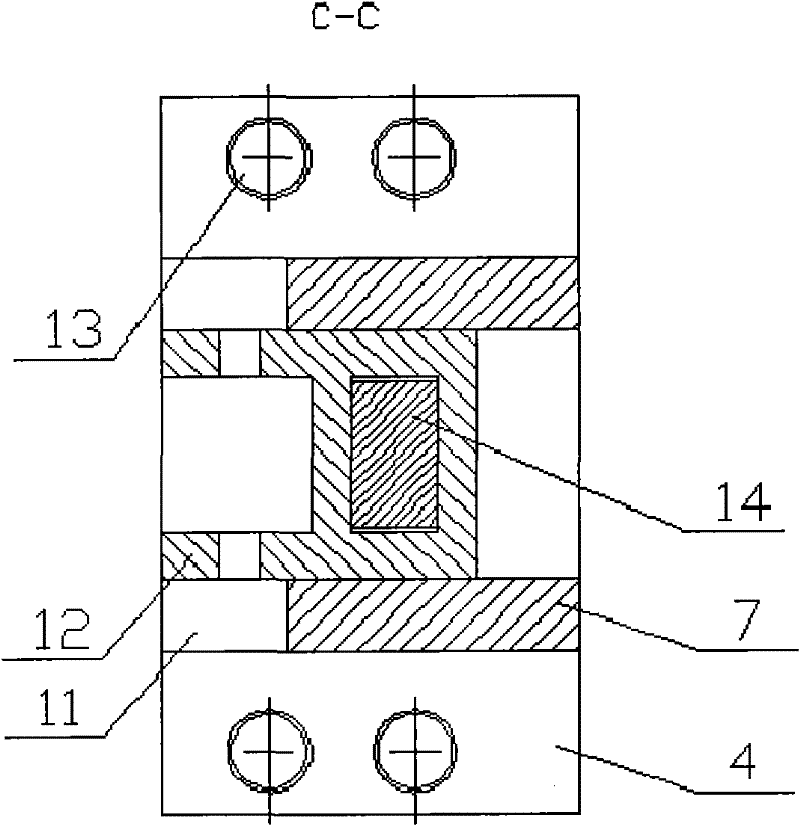

[0016] Said invention consists of figure 1 The overall structure diagram of the material testing machine, figure 2 Partial cross-sectional view of quantitative tension and compression loading machine base.

[0017] Its loading method is weight loading.

[0018] The specific function realization of this test device is as follows:

[0019] Quantitative tensile loading action process: firstly, the loading support machine 7 is fixed on the corresponding position on the fixed base 4 through the tightening screw 13, and then one end of the test piece 3 is fixed on the pin hole 5, if the experimental condition is to realize the loading of the hinged test piece , it is fixed on the pin hole, otherwise, the test piece 3 is fixed on the pin hole 5. The other end of the workpiece is fixedly placed in the guide groove in the loading support frame 7, and the test piece 3 is fixed by passing through the guide slider 12 through the guide groove with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com