Stringing method of high-tension overhead line

A high-voltage overhead and stringing technology, which is applied to the space arrangement/configuration of overhead lines/cable equipment, cables, etc., can solve the problems of complicated, cumbersome processes, and a large number of poles and pull wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

[0018] A kind of wiring method of high-voltage overhead line, it comprises the following steps:

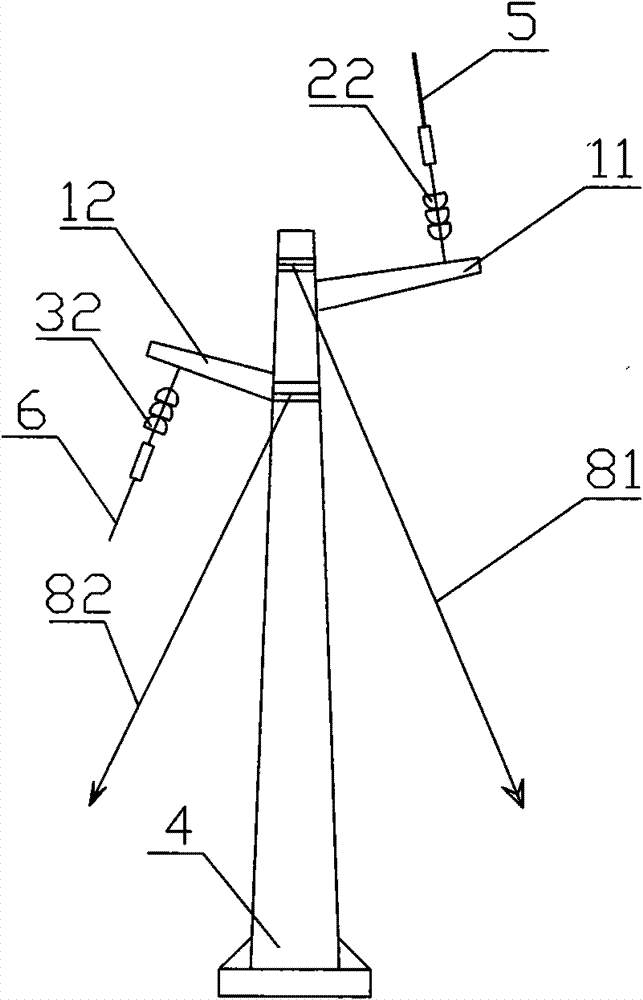

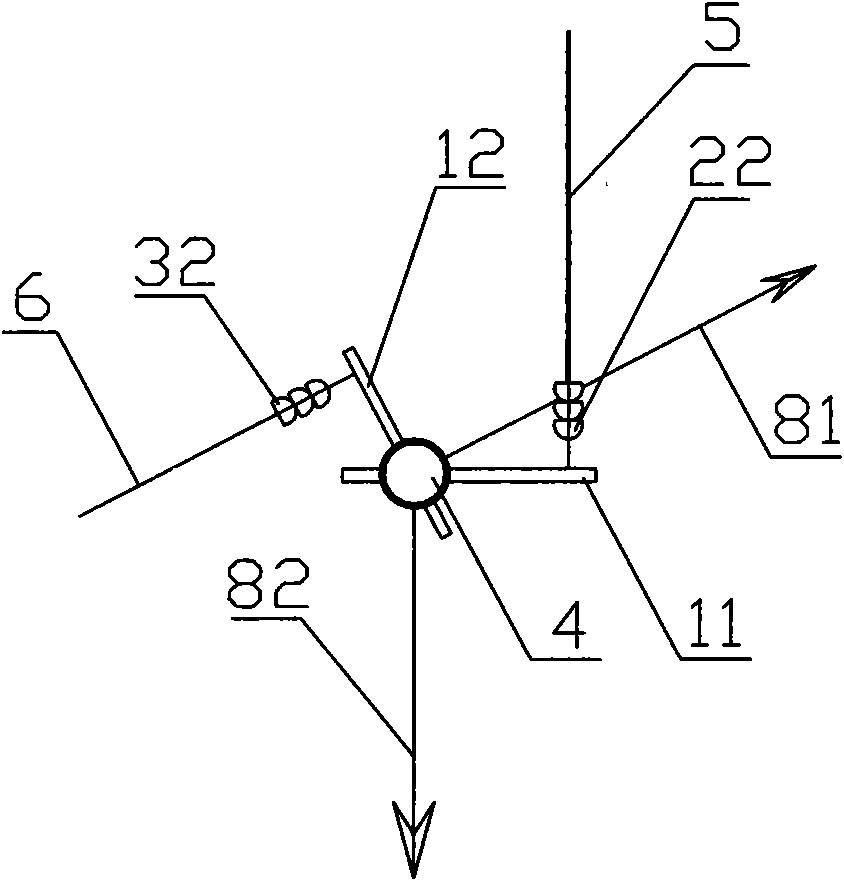

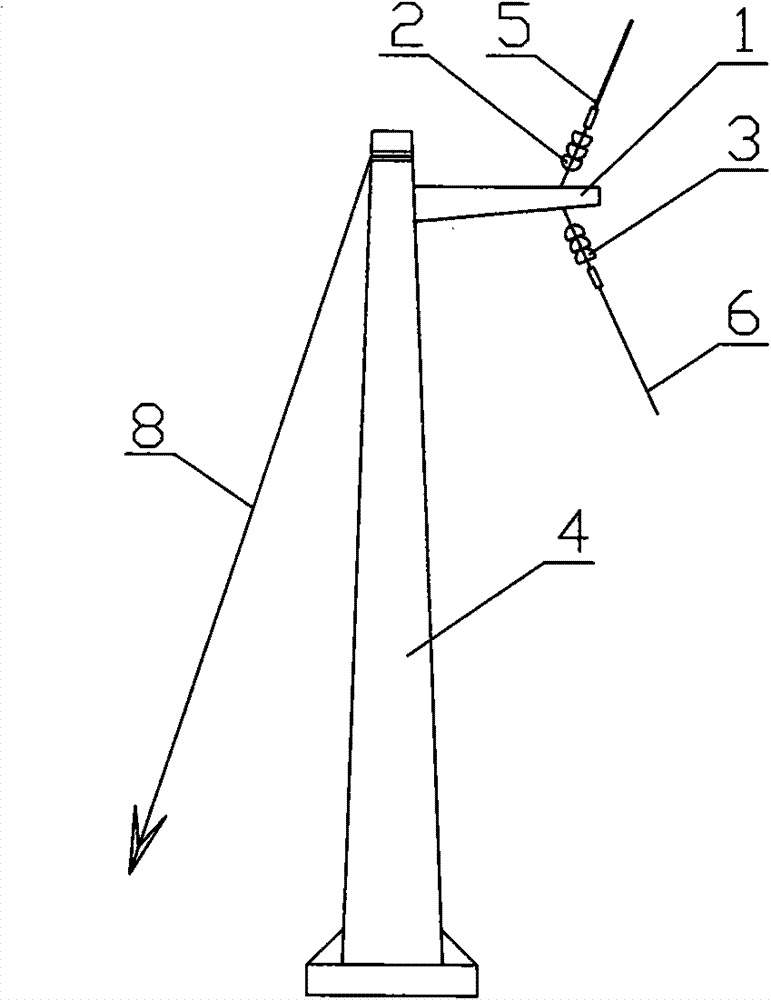

[0019] Step 1. Install an adjustable horizontal cross arm on the tower pole or line pole, set a set of main line wiring insulator strings on one side of the horizontal direction of the cross arm, and set a set of insulator strings on the other side of the horizontal direction of the cross arm A set of branch line wiring insulator strings;

[0020] Step 2, adjusting the horizontal direction of the cross arm, setting the cross arm in the middle of the direction of the main line and the direction of the branch line;

[0021] Step 3. Connect the main line to the main line wiring insulator series, connect the branch lines to the branch line wiring insulator series, and then connect the main line to the branch lines.

[0022] For the utility pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com