Double-hoisting-point pole head clamp for replacing straight-line insulator of 220 kV line steel pipe pole in electrified mode

A technology for linear insulators and live replacement, which is applied in the field of load-bearing tools, can solve the problems of insulators and operating methods not being updated in time, difficulty in carrying out live operations, and inconvenient transportation, so as to improve the difficulty of installation and improve the reliability of power supply , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

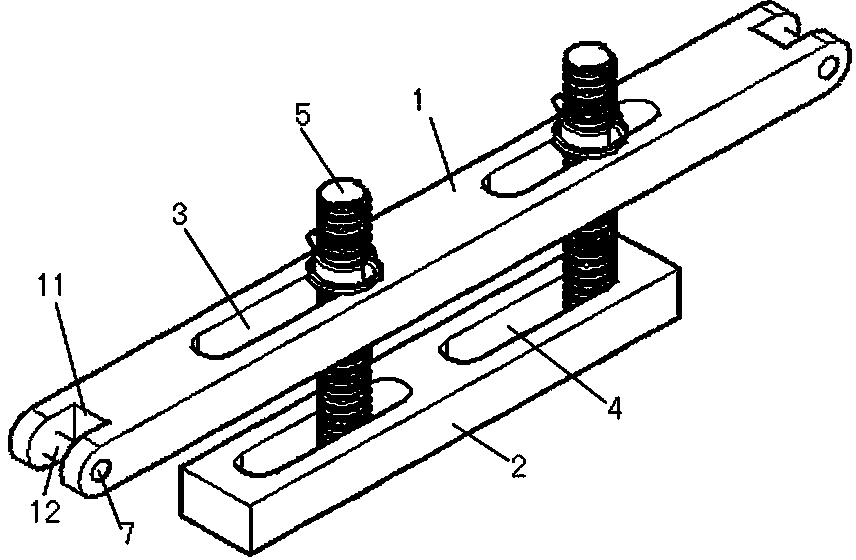

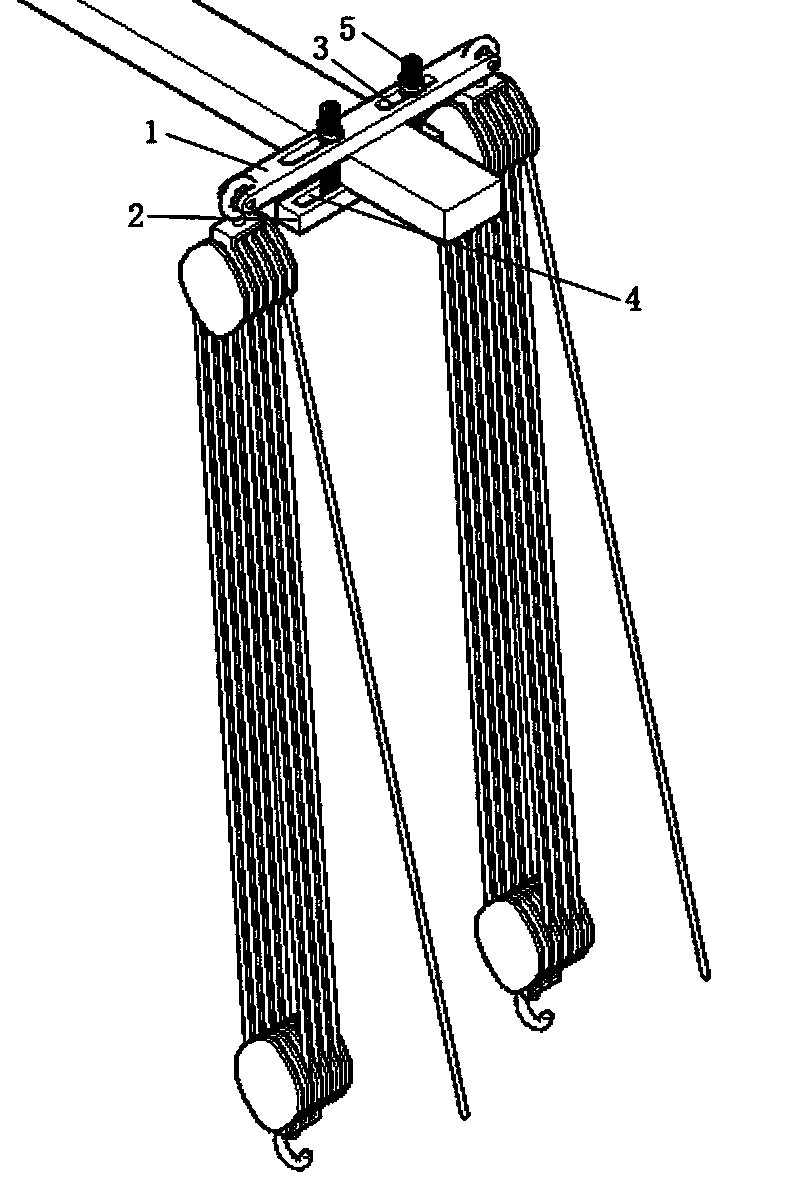

[0016] Such as figure 1 , 2 As shown, the present invention 220kV line steel pipe pole electrified replacement linear insulator used double lifting point rod head fixture includes: load-bearing upper beam 1 and fastening lower beam 2, the two sides of the load-bearing upper beam 1 are provided with two An equidistant adjustable long hole 3 is used to adjust the position where the fastening bolts need to be installed and adapt to the width of the steel pipe pole cross-arm head. A U-shaped groove 11 is respectively arranged at both ends of the load-bearing upper beam 1, and a hole 7 is arranged on both sides of the U-shaped groove 11. After the bolt 12 passes through the hole 7, it is fixed by a nut to form a tool suspension point. The tool suspension point is used to hang the insulated tool, which is the most stressed component in this fixture. The fastening lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com