Bundling device

The technology of a strapping device and driving device, which is applied to the parts and packaging of strapping machines, can solve the problems of difficult statistics and control of the amount of strapping, unstable quality, and large investment in equipment, so as to realize large-scale continuous automatic production, The effect of good quality stability and small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

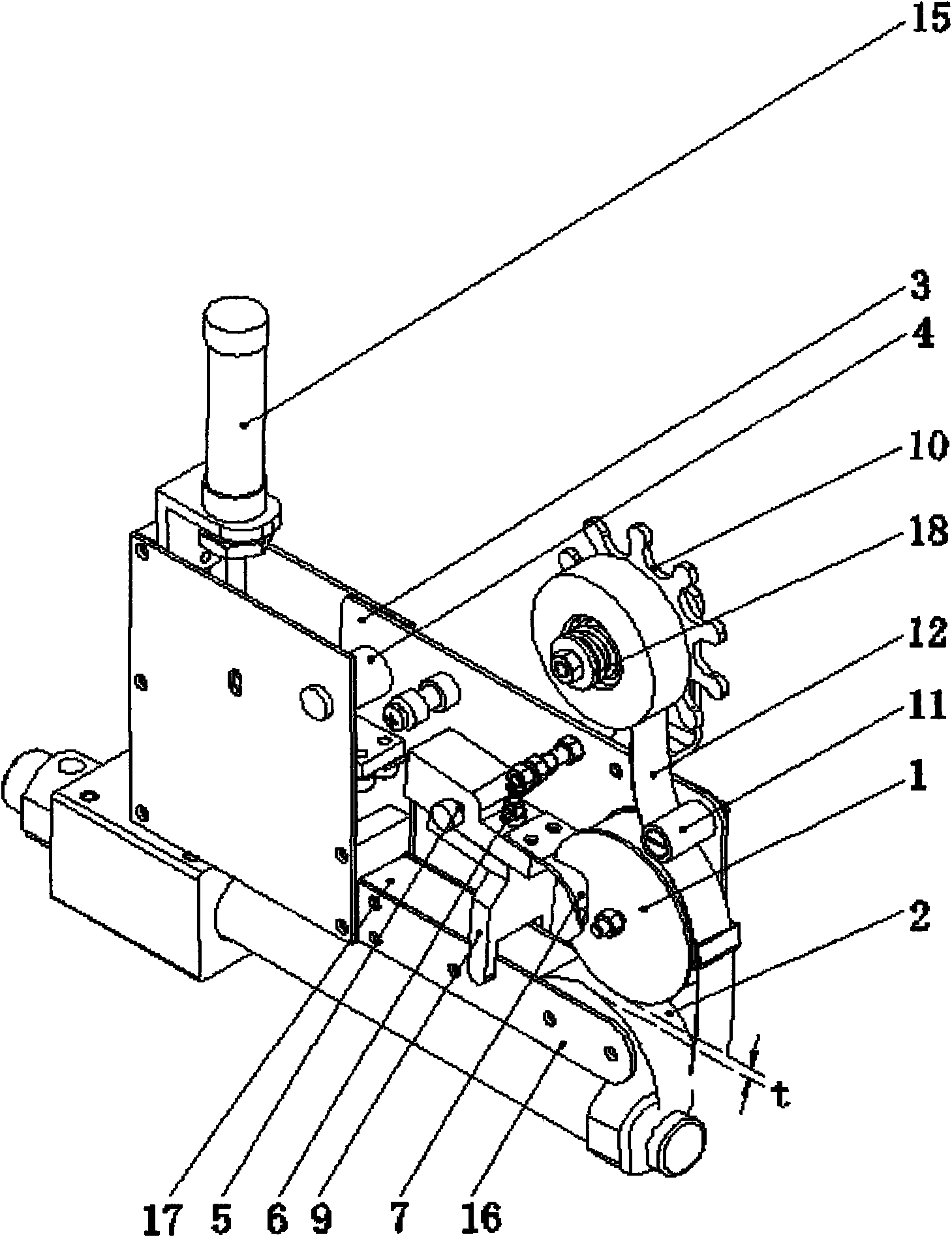

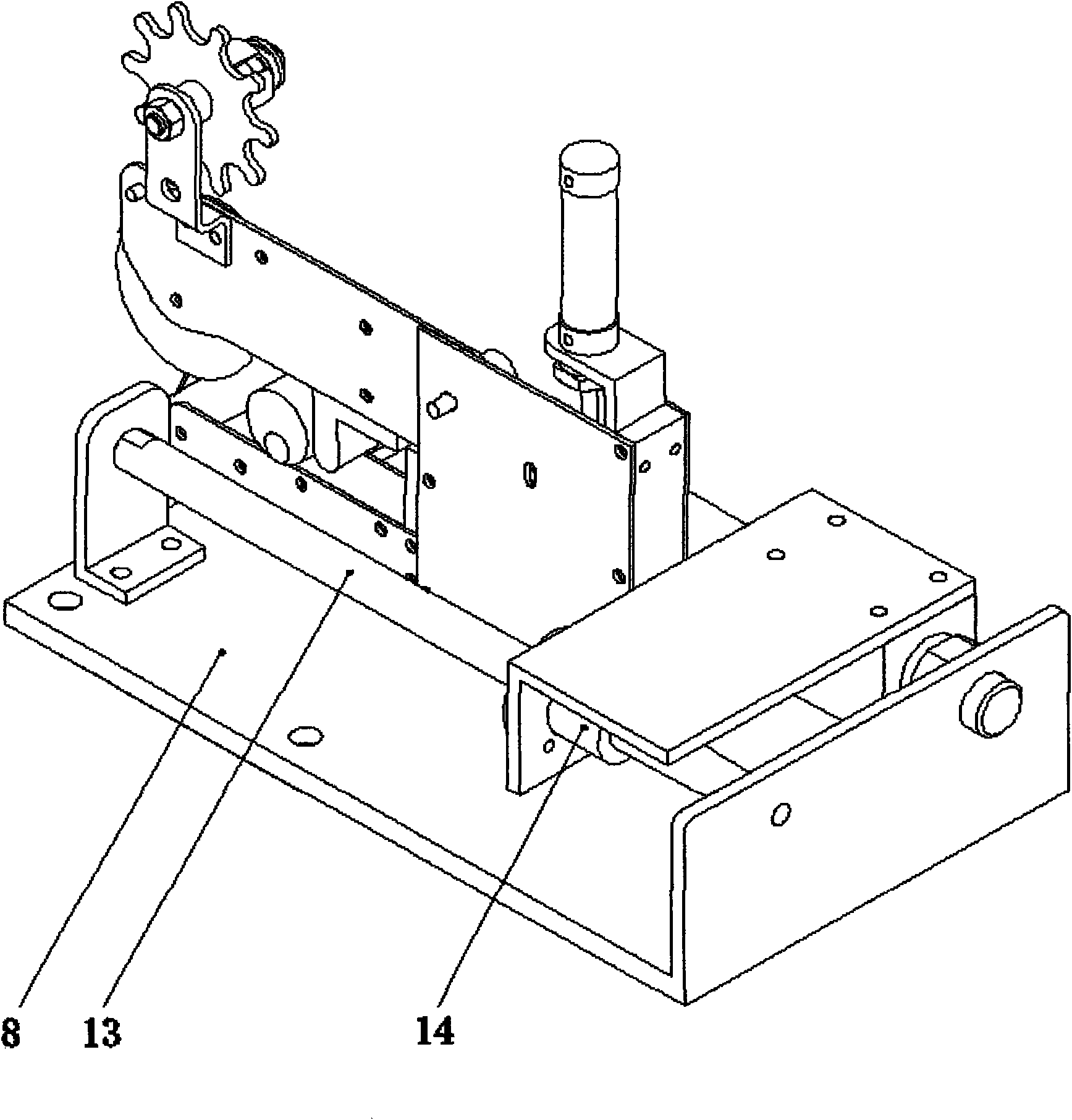

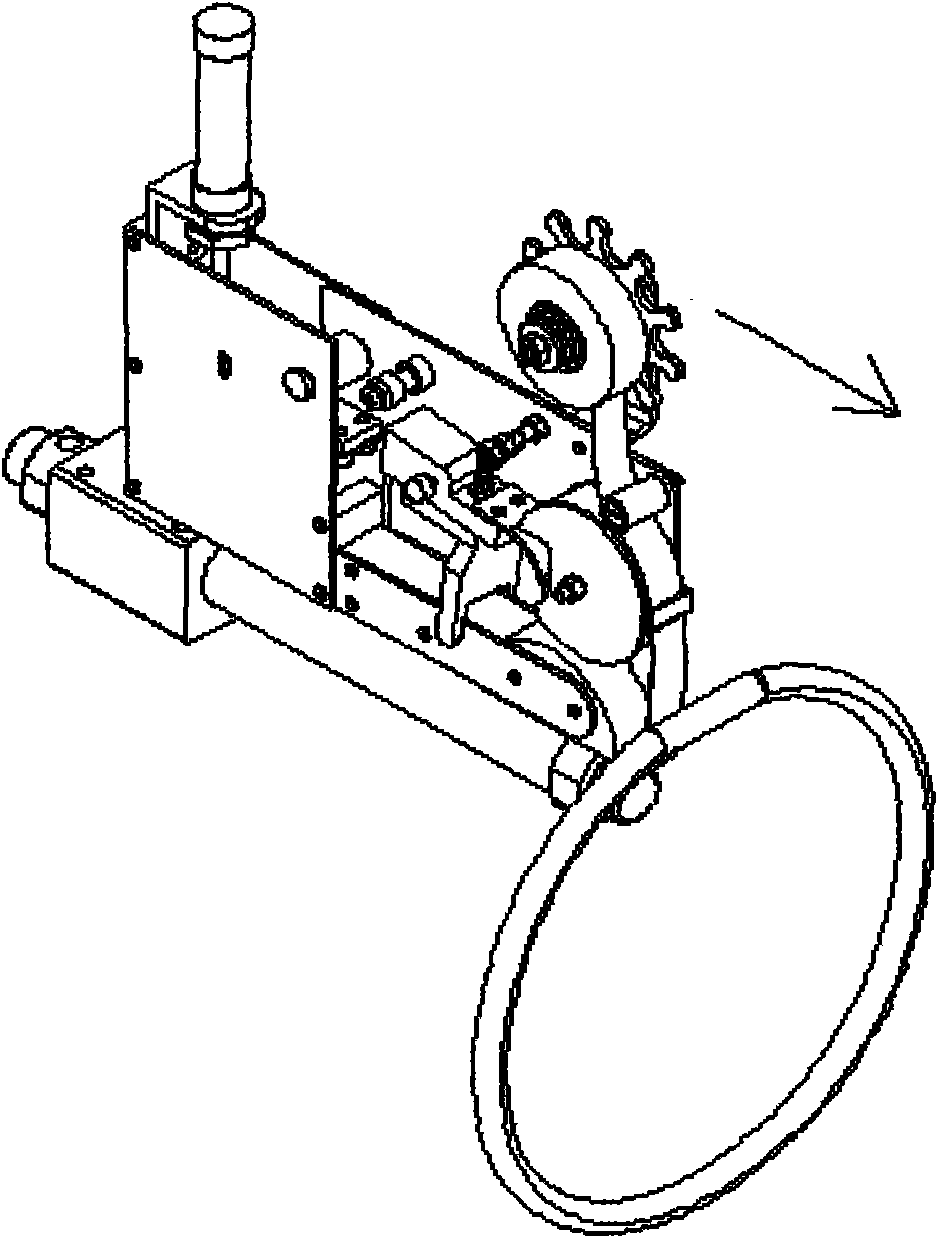

[0016] Such as figure 1 , 2 As shown, the present invention relates to a strapping device, which includes a headstock and an upper tape fixing part 1, a lower tape fixing part 2 and a tape installation shaft 18 installed on the headstock, and the upper and lower tapes are fixed The parts are distributed up and down alternately, and the gap between the two constitutes a tape wrapping channel, and the tape wrapping channel is used for the line to be bundled to carry the tape strip 12 through it.

[0017] The upper and lower adhesive tape fixing parts are preferably arc-shaped on their opposite surfaces, and the rear part of the adhesive tape wrapping channel formed by this is a flared opening with a large outside and a small inside. Thus, the surface of the upper and lower fixing parts can be smoothly contacted with the wire handle and gradually squeeze the adhesive tape so that it can be reliably bonded to the wire handle, avoiding that the surfaces of the upper and lower fix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap