Purely folding gift packing box

A packaging box and folding technology, applied in the field of pure folding gift packaging, can solve the problems of high production cost, high operating cost, and increased workload of gift installation, and achieve low production cost and use cost, and broad market application prospects , Create convenient and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

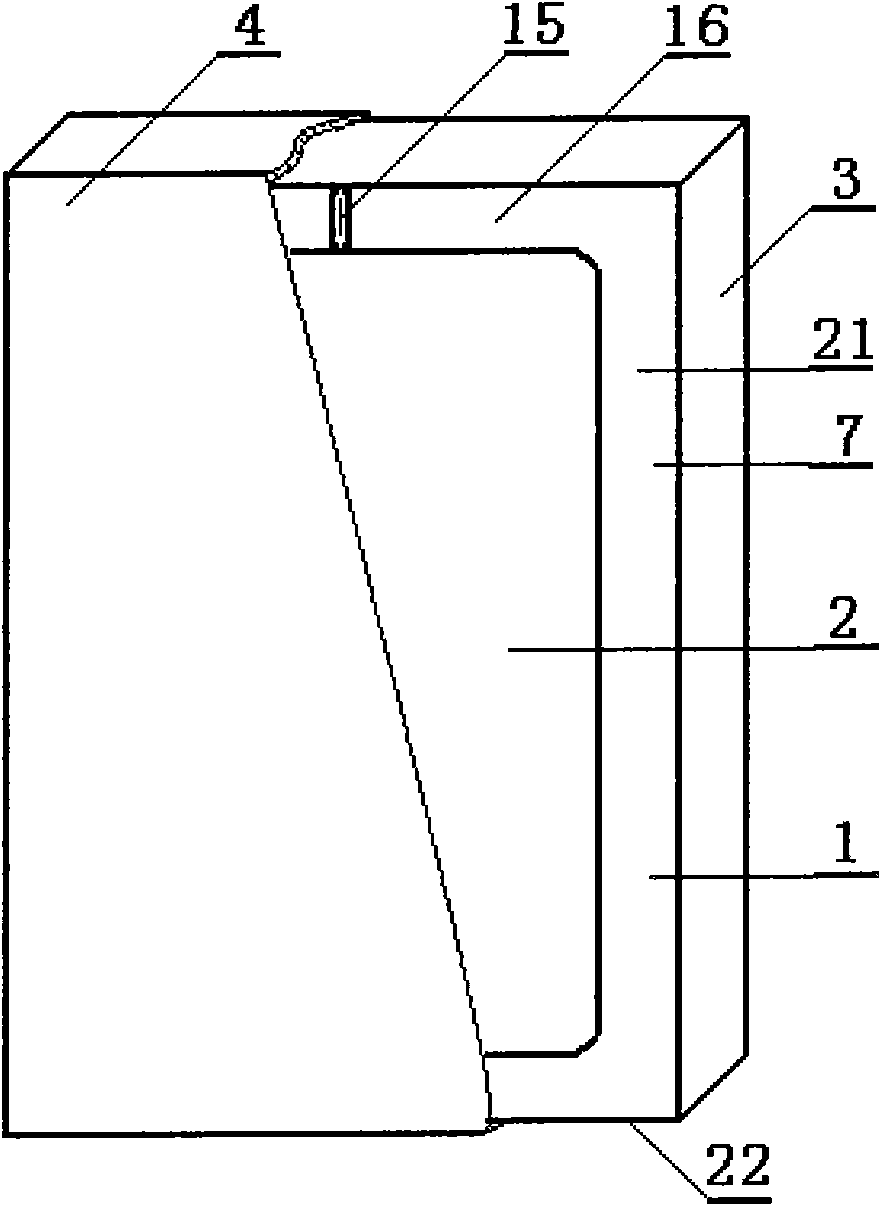

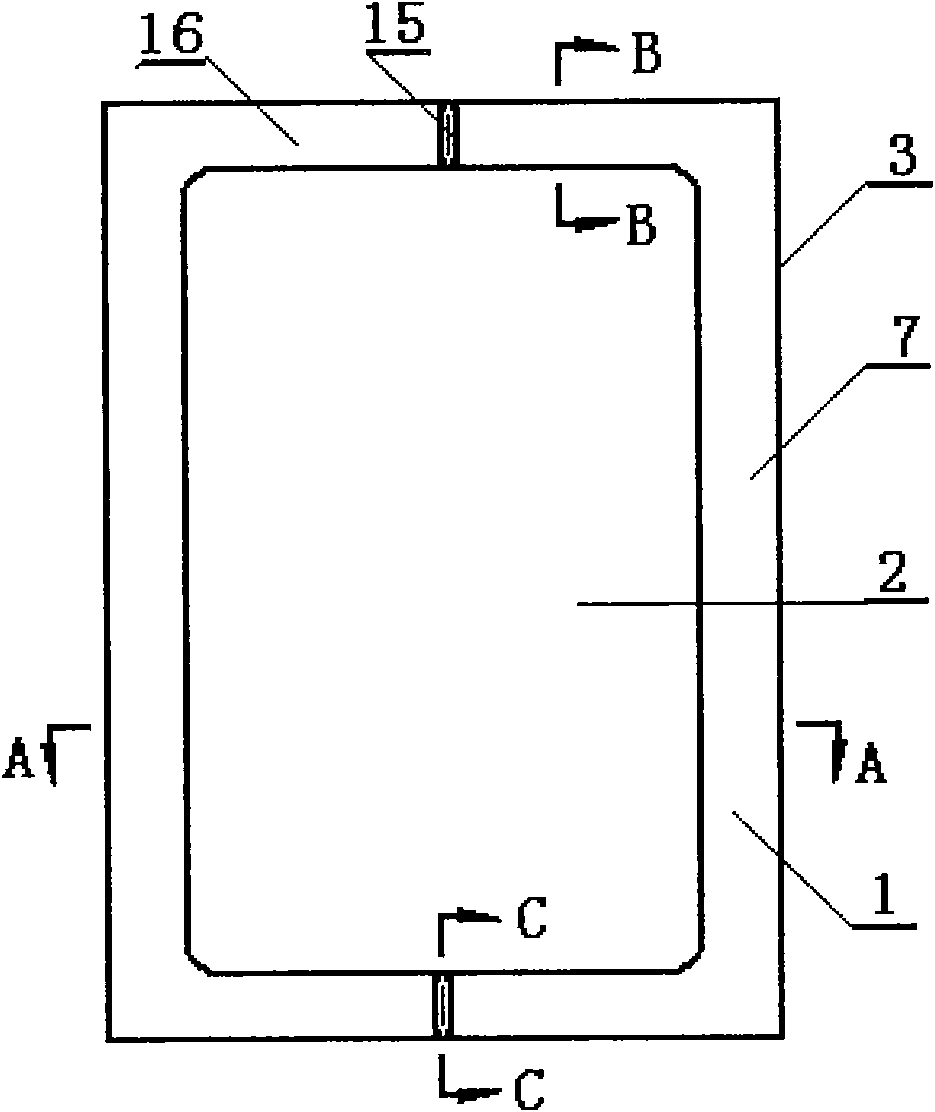

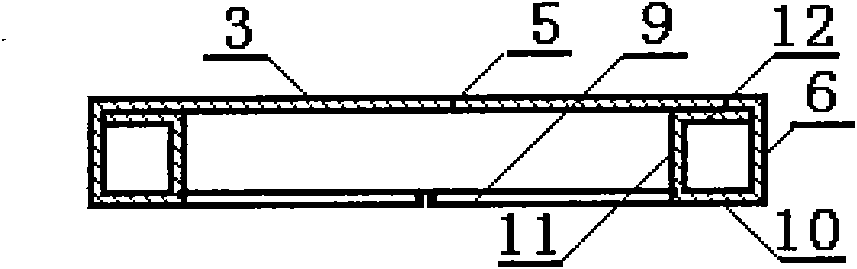

[0025] exist Figure 1-Figure 8 Among them, the main body of the pure folding gift packaging box of the present invention is composed of a box body 3 and a box cover 4 with an internal auxiliary support frame 1 and a gift storage compartment 2, and is characterized in that the box body 3 and the internal auxiliary support frame 1 are purely foldable and integrated The component is provided with an intermediate bottom plate 5, continuously arranged on the left and right sides of the intermediate bottom plate 5, and the first fold strip 6 with a width a corresponding to the thickness s of the box body, and a width b corresponding to the left and right sides of the internal auxiliary support frame 1. The width of the frame edge 7 is consistent, and the front and rear proximal ends are provided with the second folding strip 10 of the outwardly exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com