Hollow plate glass

A technology of vacuum glass plate and vacuum cavity, which is applied in the field of daylighting, heat preservation, heat collecting vacuum glass plate, and sound insulation. It can solve the problems of inconsistent expansion length and vacuum glass plate breakage, and achieve low cost, simple structure and sound insulation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

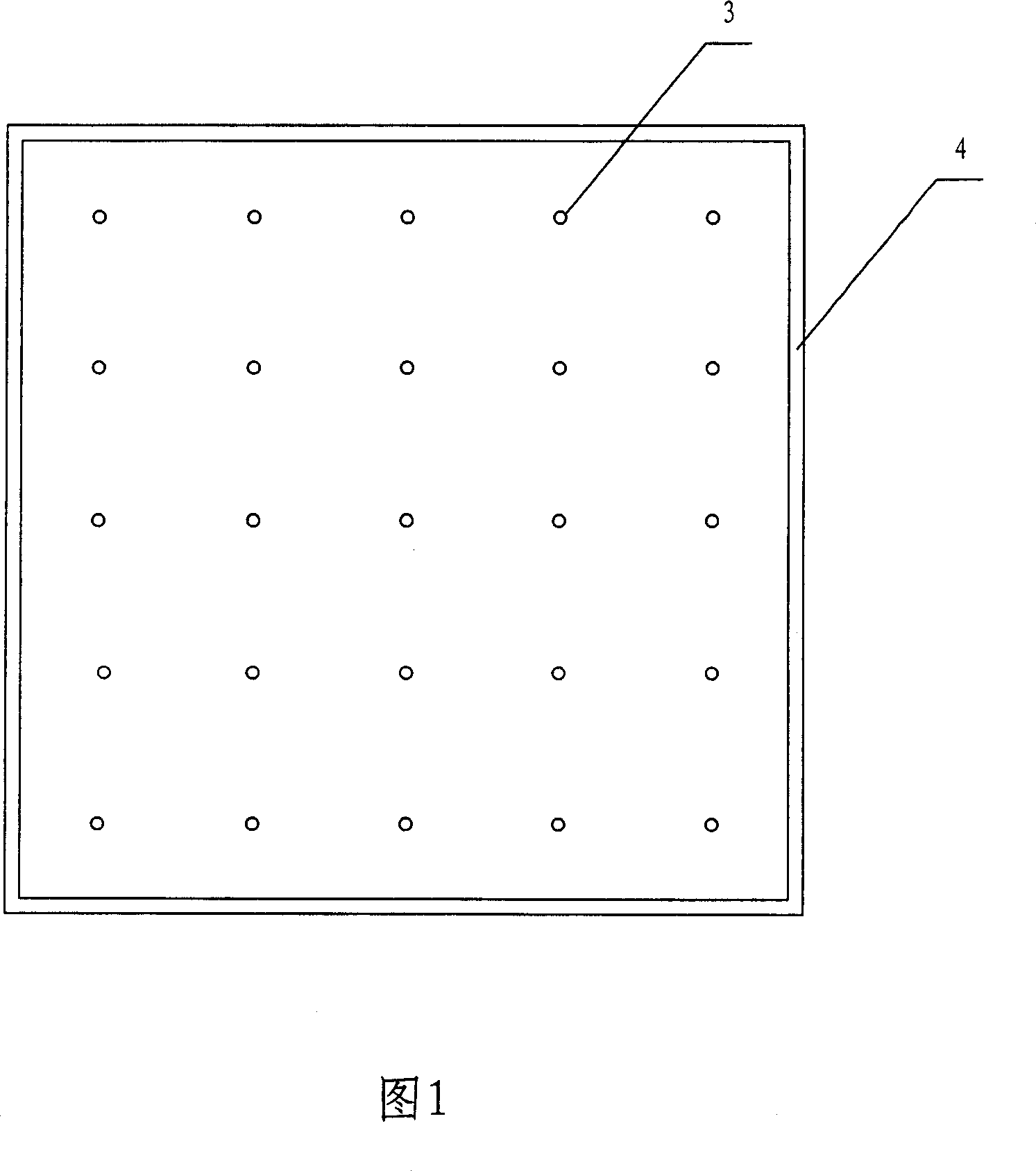

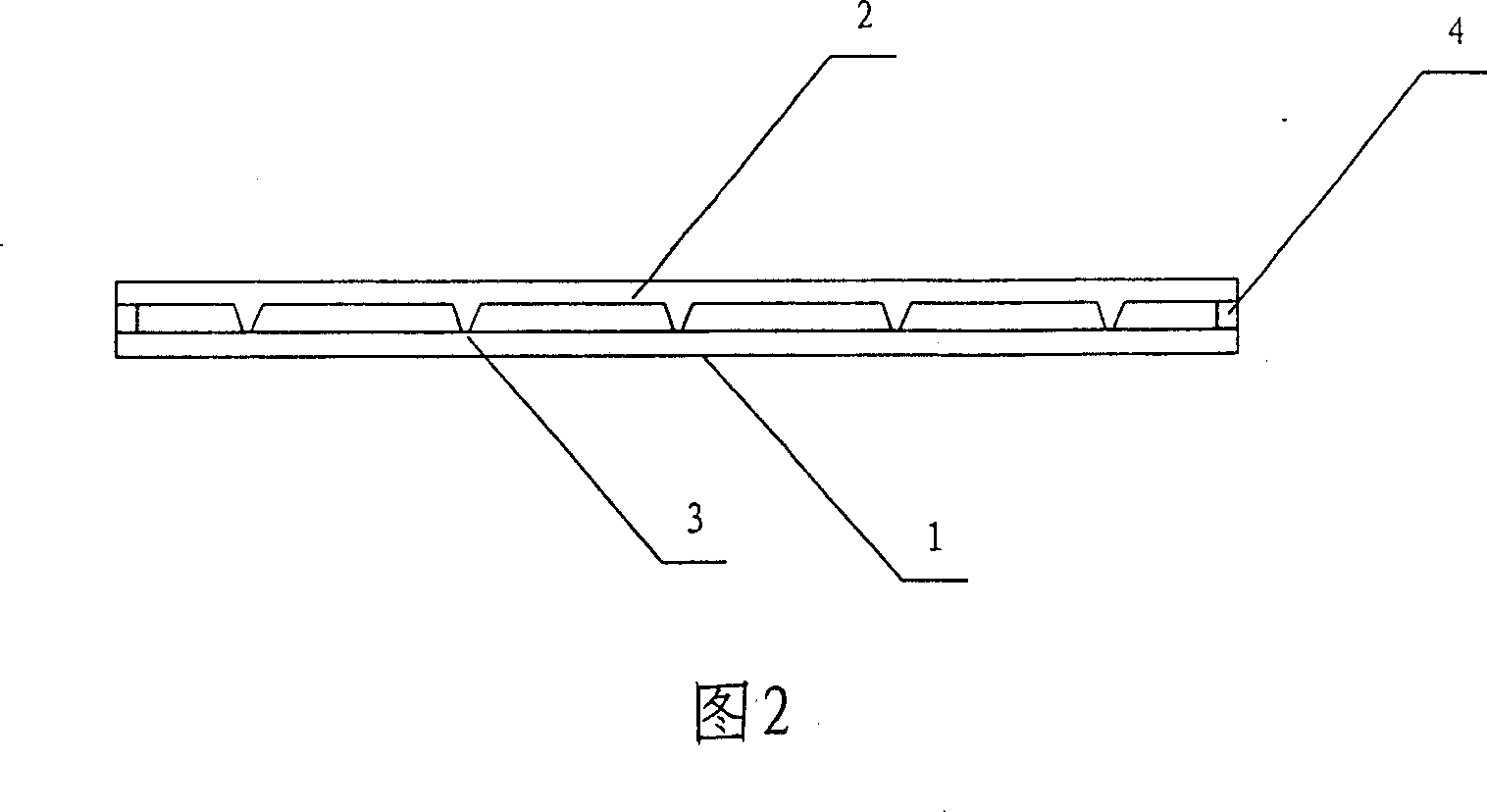

[0018] Example 1: a vacuum glass panel, consisting of two panels sealed around to form a vacuum cavity, one panel 1 is a plane; the other panel 2 is a continuous wave-shaped panel, and the connection points 3 of each wave are supported on the plane panel 1. The peripheral sealing layer 4 can be melted and coagulated with materials such as metal, rubber, plastic, etc. with a low melting point, or sealed with an adhesive.

Embodiment 2

[0019] Example 2 is basically the same as Example 1, the difference is that an evacuation nozzle is provided at the corner of the vacuum glass plate, or on the plate surface.

Embodiment 3

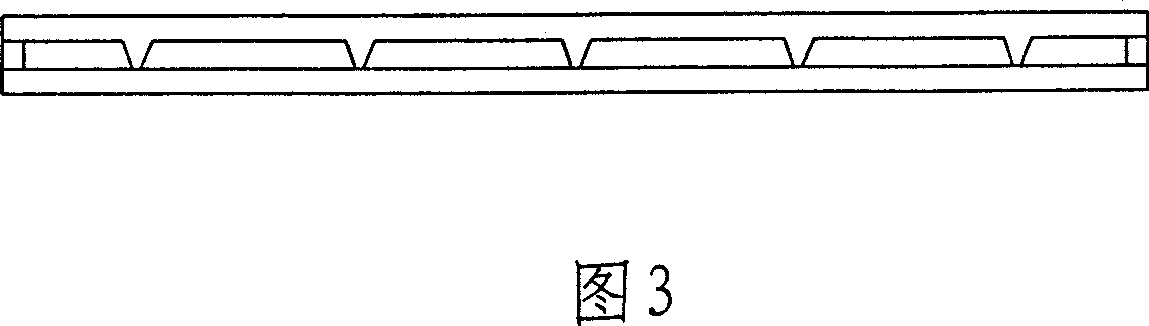

[0020] Embodiment 3: On the basis of Embodiment 1, a continuous wave-shaped panel is arranged on the other side of the flat panel 1, and the flat panel and the two continuous wave-shaped panels form two vacuum cavities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com