Waveguide laser for carrying out transverse mode control by adopting filtering film matcher

A technology of waveguide lasers and transverse modes, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of difficult to obtain high-power laser output, affect low-order mode power, and power drop, so as to increase the effective mode Field area, good mode selection effect, and the effect of increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

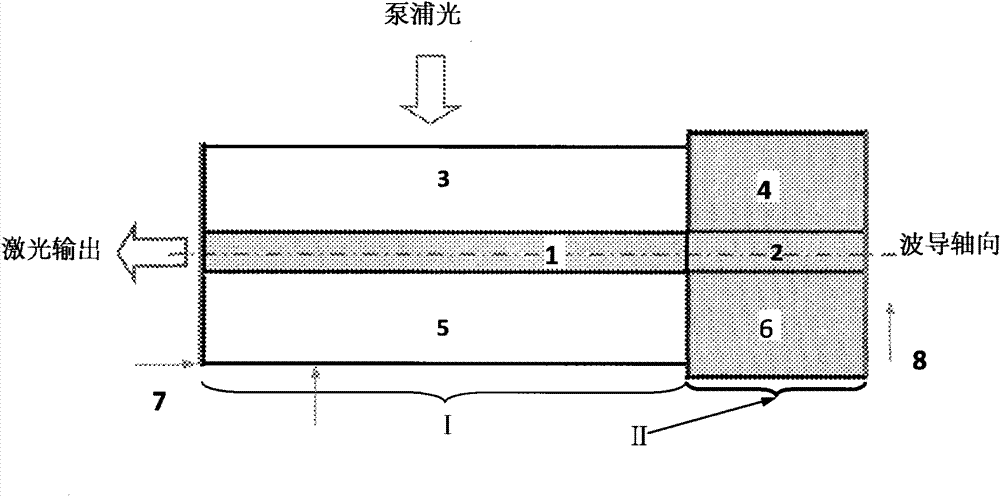

[0045] This embodiment is a slab waveguide laser using transverse mode control. Such as figure 1 As shown, the segmented slab waveguide consists of two sections I and II. Both I and II adopt a symmetrical structure. The core diameters of the guide cores (1) and (2) are both 100um. The overall size of the waveguide I is 0.4mm×4mm×12mm, and the entire waveguide size of the waveguide II is 0.5mm×5mm× 12mm. That is, the cladding (3) and substrate (5) of I are smaller than the cladding (4) and substrate (6) of II. The pump light is injected from one edge of I through the coupling device, and the laser oscillation gains gain in I. After entering II, it is completely reflected by the coating on the end face of II and returns, and then enters I. After multiple round trips, the high-order mode loss is greater than that of the low-order mode. Mode loss, the laser beam with better beam quality is finally output from the end face of II. The coating film (8) on the II end face is total...

Embodiment 2

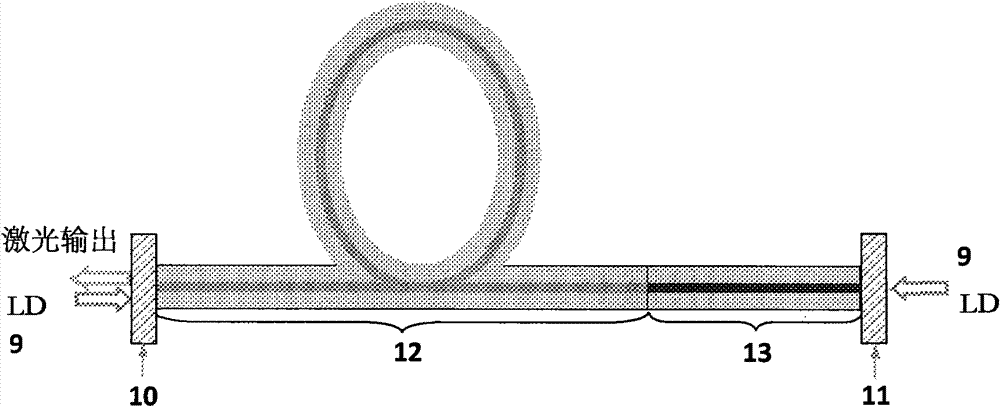

[0047] This embodiment is a fiber laser using transverse mode control, such as figure 2 shown. LD pump source (9), dichroic mirrors (10), (11) and gain fiber (12) form a basic Fabry-Perot resonator cavity, the fiber adopts segmented structure, gain fiber (12) and guide fiber (13) Have the same core diameter, same numerical aperture and cladding size. The cladding of the gain fiber (12) is quincunx, and the cladding of the conducting fiber (13) is circular. The dichroic mirror (10) is close to the end face of the optical fiber (12), and it is highly transparent to the pump light and highly reflective to the fiber laser; the output mirror (11) is highly transparent to the incident pump light and partially transparent to the fiber laser. The pumping light is injected into the inner cladding of the optical fiber after passing through the dichroic mirror from both ends of the optical fiber, and excites laser oscillation in the optical fiber section (12). In one return journey, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com